Method for improving performance of tantalum powder, tantalum powder and tantalum capacitor anode block prepared from the tantalum powder

A technology of tantalum powder and high performance, which is applied in the field of tantalum capacitor anode blocks, can solve the problems of tantalum powder with high bulk density, failure to meet product requirements, and large product weight deviation, so as to reduce friction damage rate, improve production efficiency, and improve The effect of molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The specific volume of the tantalum powder used is 50000μF·V / g.

[0015] Weigh 500g of tantalum powder, 15g of stearic acid, and 10g of polyethylene glycol; measure 200mL of absolute ethanol;

[0016] Mix the weighed stearic acid, polyethylene glycol and measured absolute ethanol in a beaker, heat to 60°C, keep the temperature for 10 minutes, stir and dissolve, and after the polyethylene glycol and stearic acid are completely dissolved, the modified Sexual fluid;

[0017] Add the modified liquid to the tantalum powder, mix, heat to 60°C, mix at a constant temperature for 3 hours, and naturally cool to room temperature to obtain the modified tantalum powder;

[0018] Detect the fluidity and bulk density of modified tantalum powder;

[0019] Put the modified tantalum powder in the molding die, press molding, the molding weight is 45mg / a tantalum block, and the pressing density is 5.2g / cm 3 ;Randomly select 10 molded products, weigh them, and calculate the relative erro...

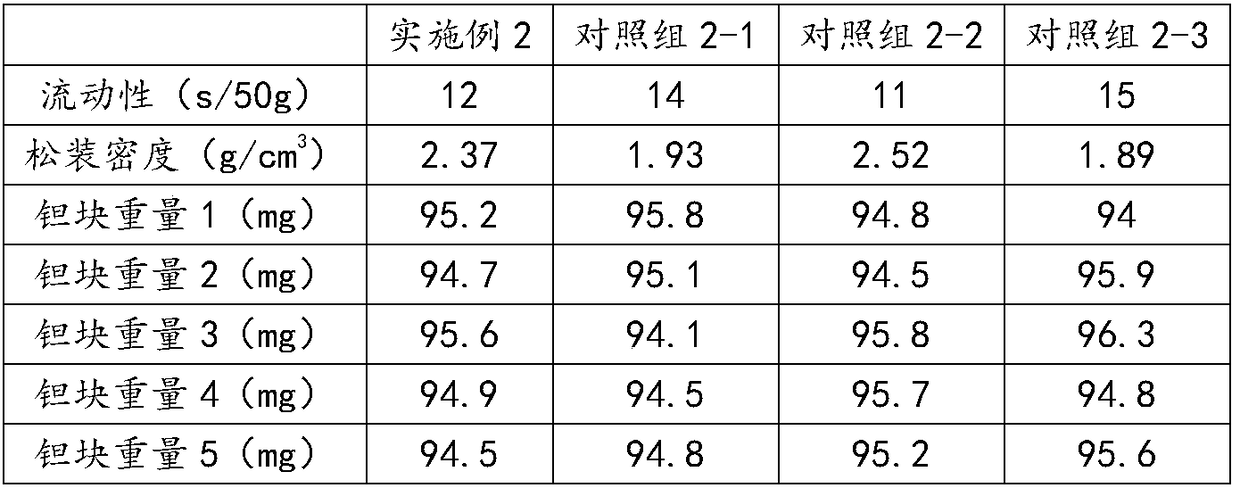

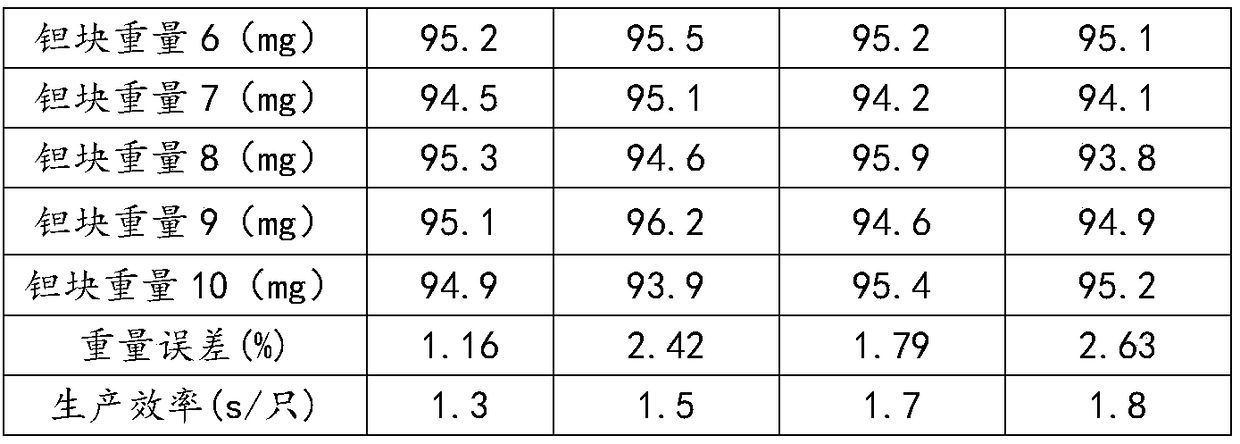

Embodiment 2

[0030] The specific volume of tantalum powder is 8000μF·V / g.

[0031] Weigh 1000g of tantalum powder, 20g of stearic acid, 10g of polyethylene glycol; measure 150mL of absolute ethanol;

[0032] Mix the weighed stearic acid, polyethylene glycol and measured absolute ethanol in a beaker, heat to 50°C, keep the temperature for 15 minutes, stir and dissolve, and after the polyethylene glycol and stearic acid are completely dissolved, the modified Sexual fluid;

[0033] Add the modified liquid to the tantalum powder, mix, heat to 50°C, mix at a constant temperature for 4 hours, and naturally cool to room temperature to obtain the modified tantalum powder;

[0034] Detect the fluidity and bulk density of modified tantalum powder;

[0035] Put the modified tantalum powder in the molding die, press molding, the molding weight is 95mg / a tantalum block, and the pressing density is 5.2g / cm 3 ;Randomly select 10 molded products, weigh them, and calculate the relative error, and count ...

Embodiment 3

[0047] The specific volume of the tantalum powder used is 3500μF·V / g.

[0048] Weigh 2000g of tantalum powder, 20g of stearic acid, 10g of polyethylene glycol; measure 90mL of absolute ethanol;

[0049] Mix the weighed stearic acid, polyethylene glycol and measured absolute ethanol in a beaker, heat to 70°C, keep the temperature for 10 minutes, stir and dissolve, and after the polyethylene glycol and stearic acid are completely dissolved, the modified Sexual fluid;

[0050] Add the modified liquid to the tantalum powder, mix, heat to 70°C, mix at a constant temperature for 2 hours, and naturally cool to room temperature to obtain modified tantalum powder;

[0051] Detect the fluidity and bulk density of modified tantalum powder;

[0052] Put the modified tantalum powder in the molding die, press molding, the molding weight is 150mg / a tantalum block, and the pressing density is 5.2g / cm 3 ;Randomly select 10 molded products, weigh them, and calculate the relative error, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com