End-window X ray tube

A technology of X-ray tube and end window, which is applied in the directions of X-ray tube, X-ray tube electrode, X-ray tube parts, etc. Productization and mass production, reducing difficulty and manufacturing costs, and meeting the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

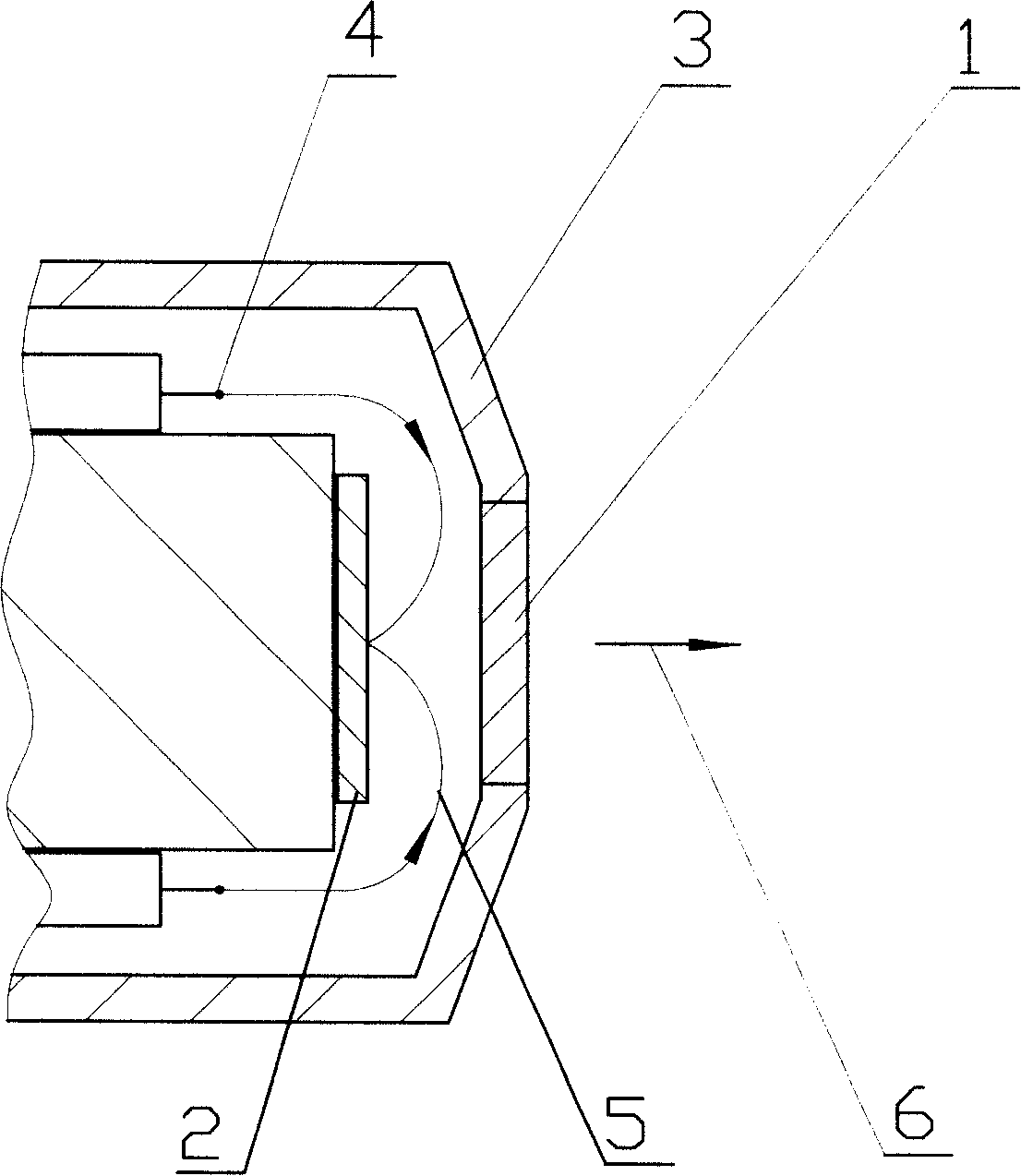

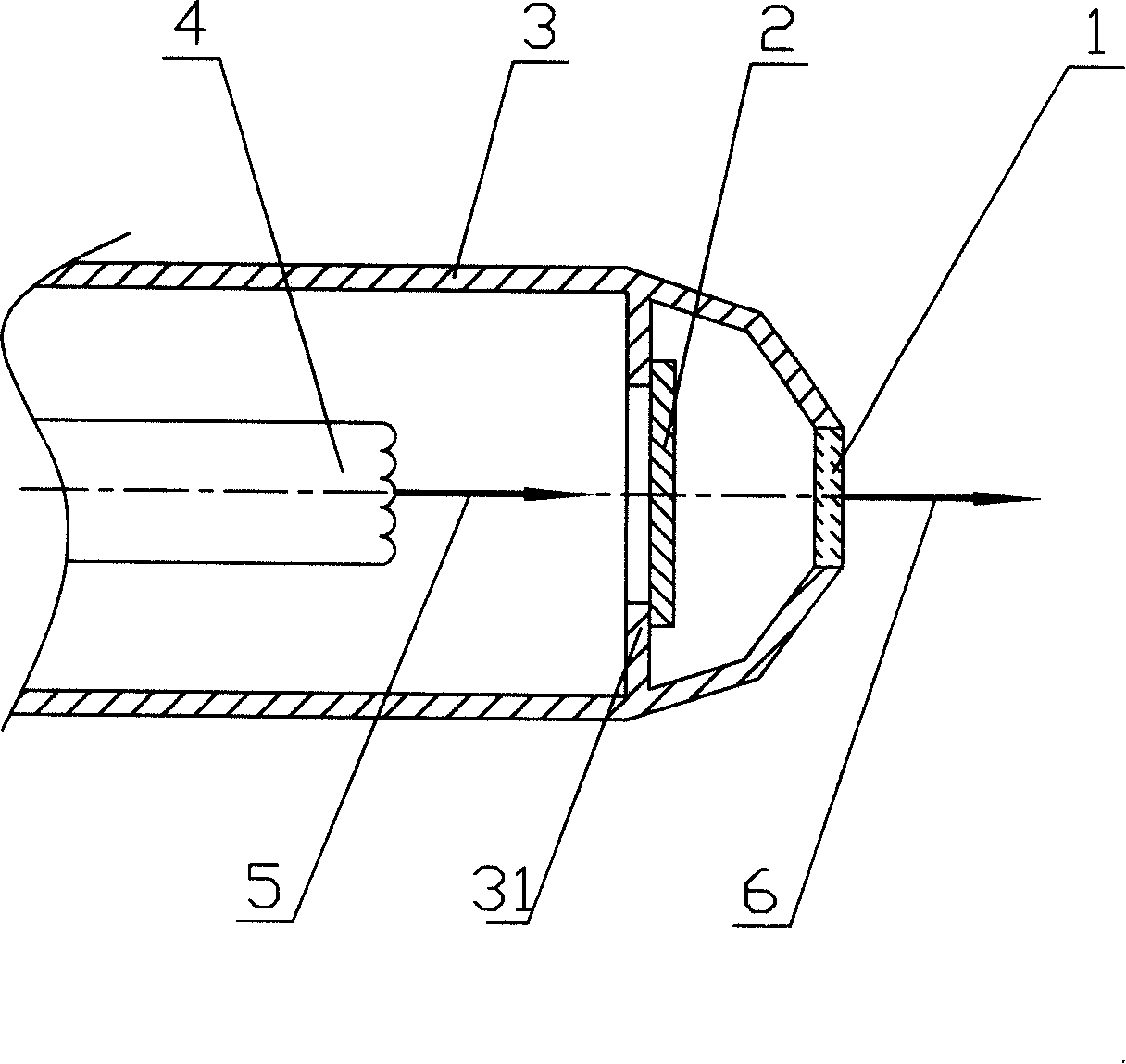

[0016] The end window X-ray tube described in this embodiment consists of figure 2 As shown, it includes a housing 3, a cathode filament 4 for emitting an electron beam 5, a thin film anode target 2, and a beryllium window 1. The shell 3 is made of copper-based material, and a ring-shaped bracket 31 for installing a thin film anode is installed inside the shell 3, and the shell 3 is directly grounded. The cathode filament 4 is encapsulated in the housing 3 and is powered by a voltage of -40kV. The beryllium window 1 is arranged on the end surface of the housing 3 and is located directly in front of the electron beam 5. The thin-film anode target 2 is arranged between the cathode filament 4 and the beryllium window 1. In this example, a thin-film molybdenum sheet with a thickness of 20 μm is used as the thin-film anode target 2. The thin-film anode target 2 is welded to the ring frame 31 inside the housing 3 , It can ensure good electrical and thermal contact. Because of the good t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com