Uniform-section blade-type microscale turbine electric spark machining device and process method thereof

A processing device and EDM technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low machining accuracy and large deformation of micro-scale turbine blades, reduce the difficulty of design and manufacturing, and reduce the processing time. The effect of deforming and simplifying the motion track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

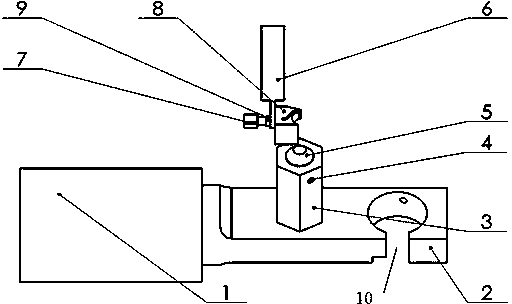

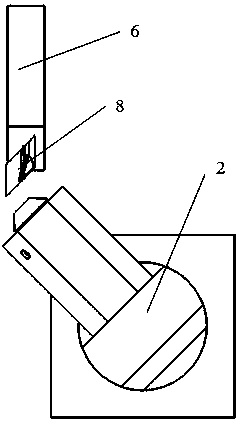

[0033] Please refer to figure 1 As shown, a constant-section airfoil micro-scale turbine electric discharge machining device includes a clamping rod 6, an integrated positioning plate 2, an indexing prism 3 and a reference base 1, and the electrode 8 is installed on the clamping rod with screws 7 and nuts 9. On the rod 6, after adjusting the position, clamp it, and then connect the clamping rod 6 to the spindle of the machine tool; position the workpiece 5 on the indexing prism 3, and lock it with the locking screw 4 to make the two become a rigid body. The degree prism 3 is positioned and clamped on the integrated positioning plate 2; finally, the integrated positioning plate 2 is installed on the reference base 1, rotated to adjust the angle and then locked.

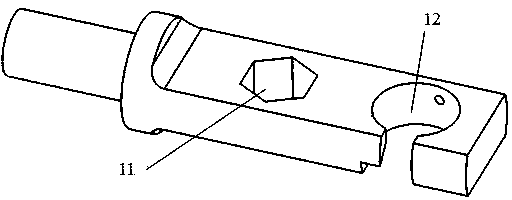

[0034] Please refer to figure 1 and figure 2 As shown, the integrated positioning plate 2 is a positioning plate for processing the electrode 8 and the workpiece 5, and the regular hexagonal hole 11 for positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com