Measuring processing performing head applicable to hole forming in aircraft skin

An aircraft skin and executive head technology, applied in the field of measurement and processing executive heads, can solve problems such as tool breakage, coordinate conversion errors, affecting hole position accuracy, etc., to reduce skin deformation and vibration, eliminate coordinate conversion errors, The effect of improving hole size accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

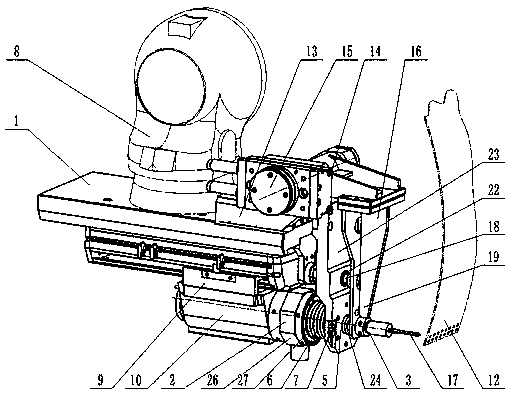

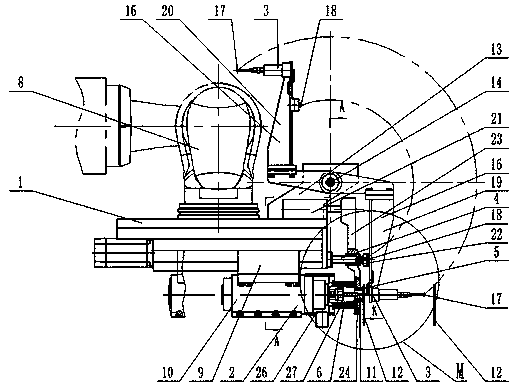

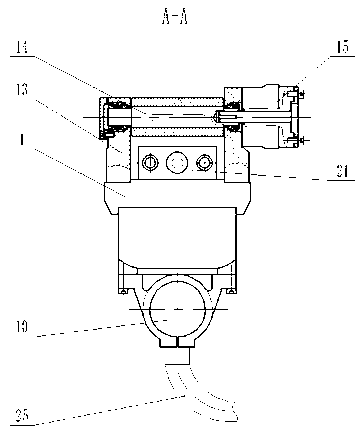

[0033] Such as figure 1 As shown, a measuring and processing executive head suitable for aircraft skin drilling, including a frame 1, an axially movable power head system 2, an indexable coaxial measuring head system 3, a positioning shaft 4, and an auxiliary pressing system 5. Vacuum chamber 6;

[0034] Such as figure 1As shown, the frame 1 is located inside the execution head to realize the installation of various system components; the top of the frame 1 has a mechanical arm connection structure, which is connected to the end 8 of the mechanical arm, and the entire execution head is driven by the mechanical arm to perform multi-axis motion. Realize the position transfer of the execution head between multiple hole positions and the adjustment of the hole making direction;

[0035] Such as figure 1 and figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com