Assembling positioning mechanism and method of draught fan impeller blades and draught fan impeller chassis

A technology of fan impeller and positioning mechanism, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high operator requirements, difficulty in ensuring the blade positioning angle, complicated operation, etc., to improve welding accuracy and quality, improve assembly and welding efficiency, and ensure the effect of positioning consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

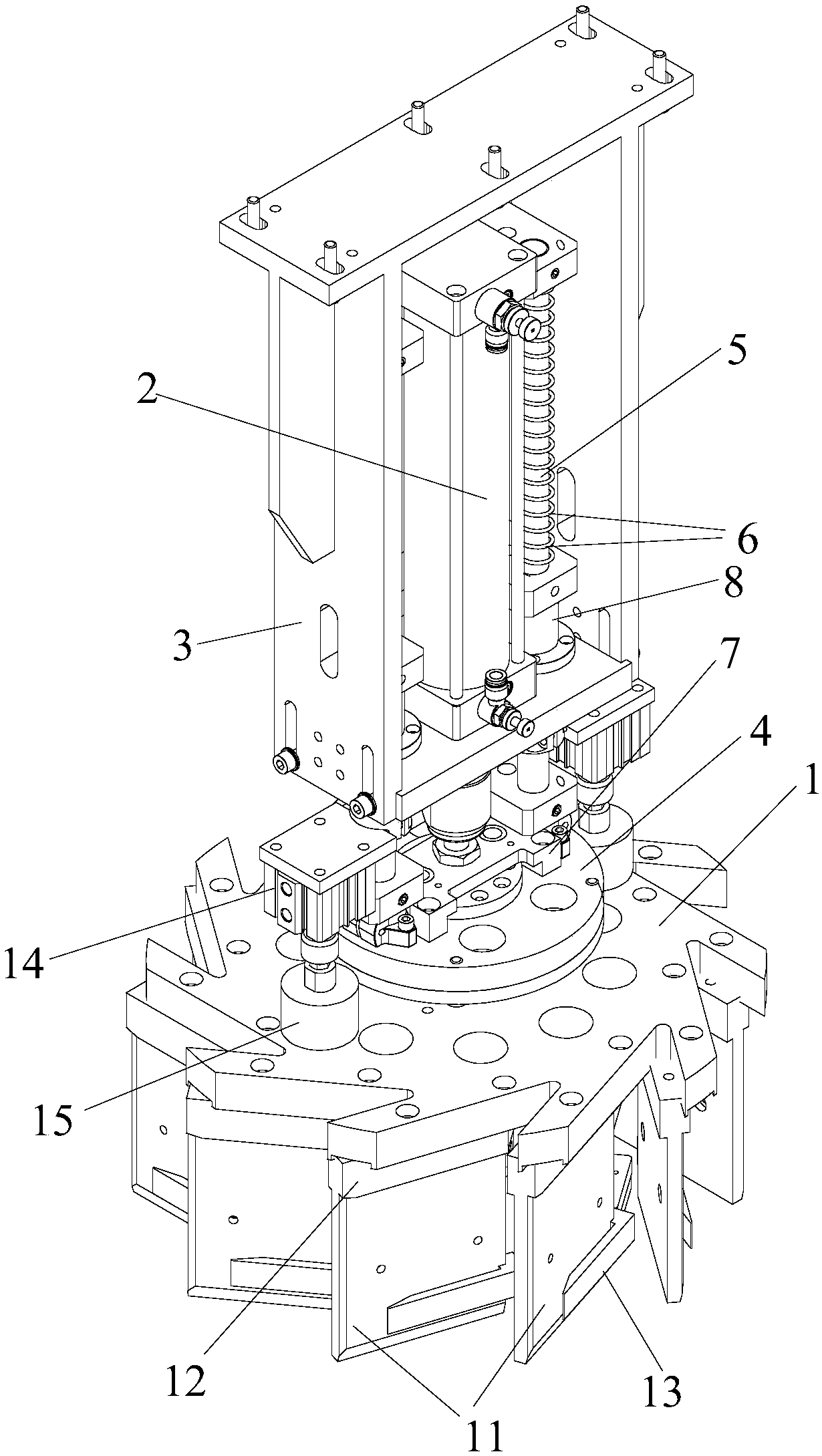

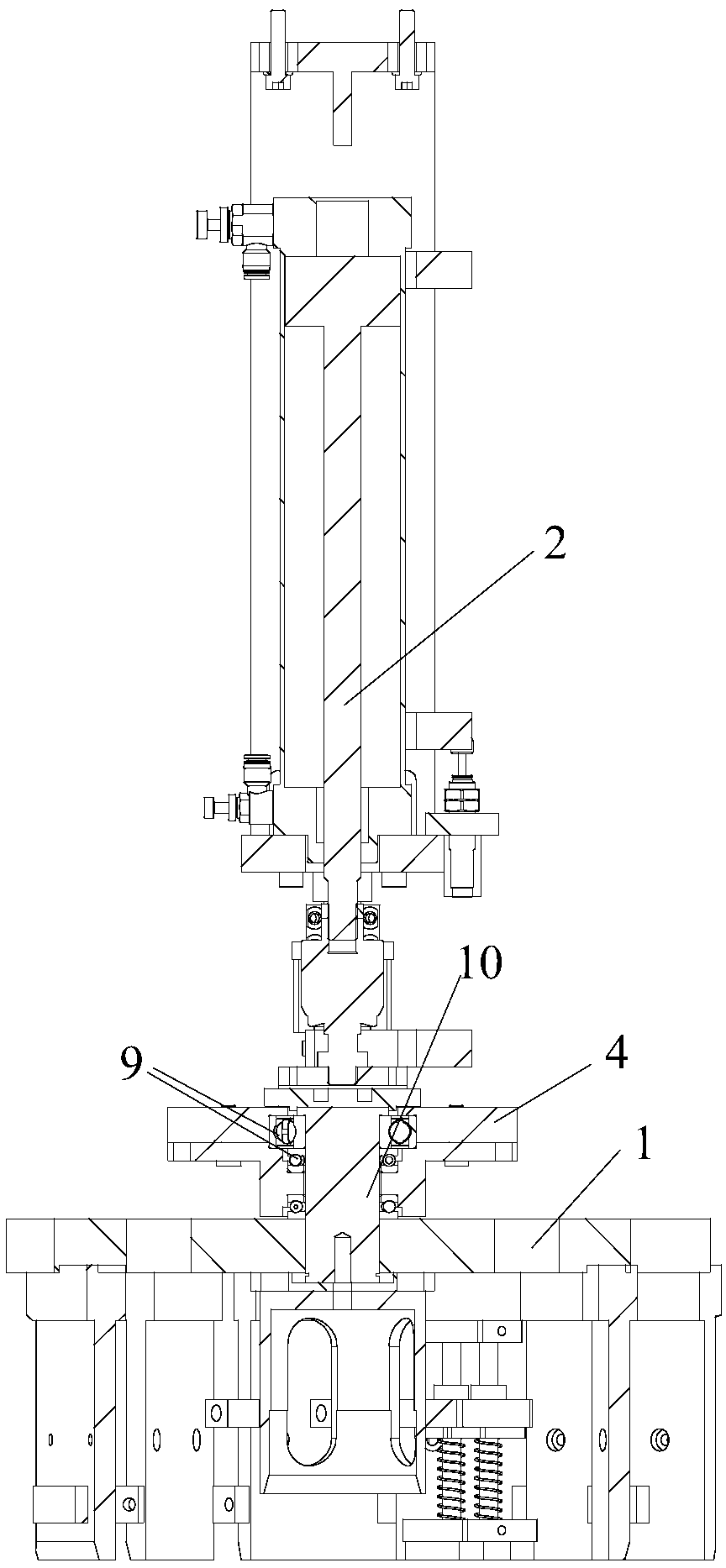

[0040] Such as Figure 1 to Figure 5 As shown, the assembly and positioning mechanism of the fan impeller blade and the fan impeller chassis of the present invention is characterized in that: comprising:

[0041]It is used to press and position the chassis 24 and be rotatable, and is used to correct the blade 23 and position it on the downward pressure positioning device on the chassis 24;

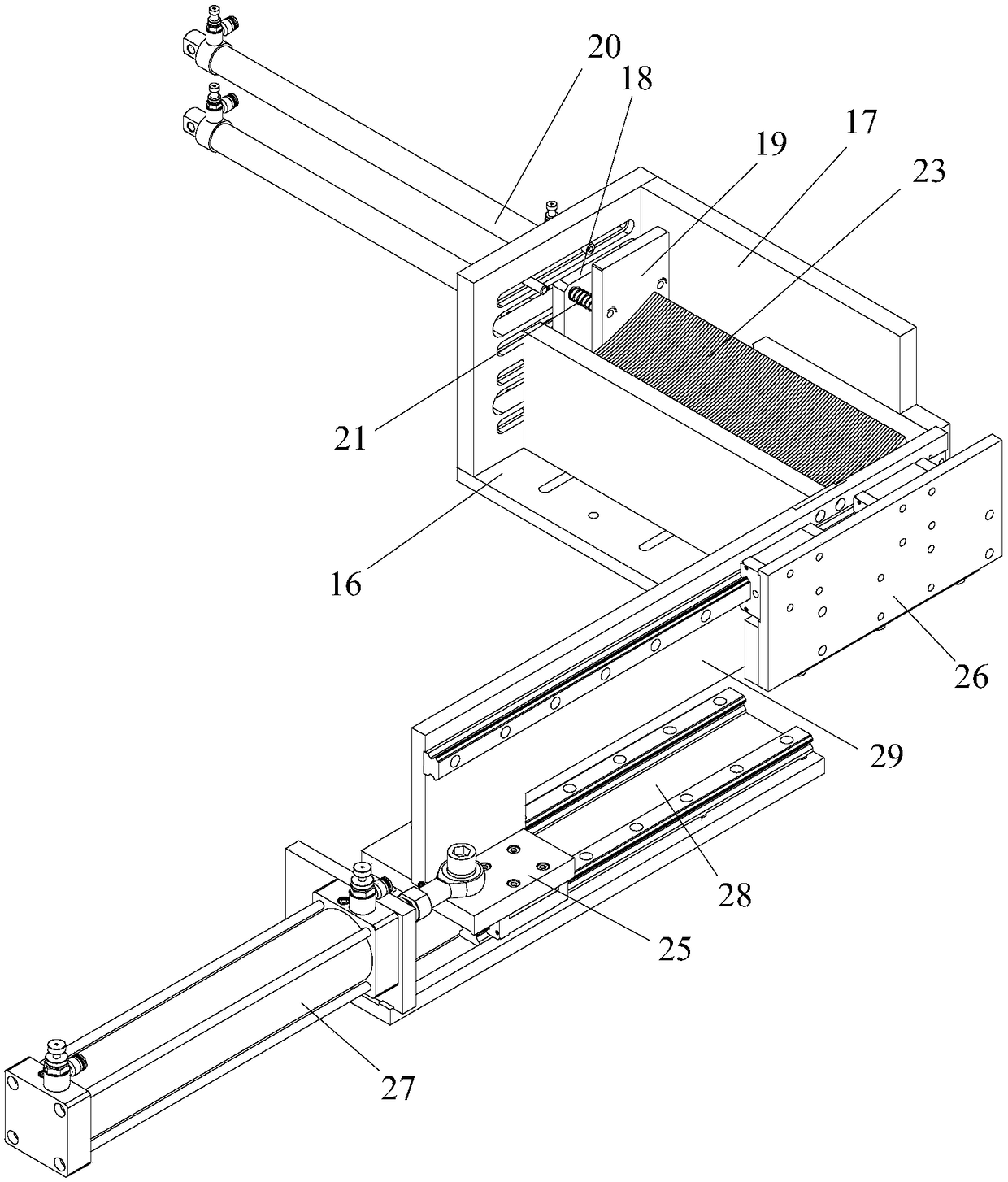

[0042] And it is used to arrange and push the blades 23 to the output station, and push the blades 23 of the output station to the push-down positioning device one by one;

[0043] Wherein, the pressing positioning device is located above the chassis positioning station, and includes a fixed mold 1 for correcting and positioning the blade 23 and a holding part for pressing the fixed mold 1 onto the chassis 24. The fixed mold 1 and the holding part Connected and located above the chassis positioning station, the fixed mold 1 is evenly equipped with welding stations for the blades 23 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com