A detection device and method for the radial stiffness of a bearing ring with an installation side

A bearing ring, radial stiffness technology, applied in the direction of mechanical bearing testing, etc., can solve the problem of the fixed installation method of the tested bearing ring, the measurement data calculation method of the loading method and the low accuracy of the result judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail in conjunction with accompanying drawing and specific embodiment:

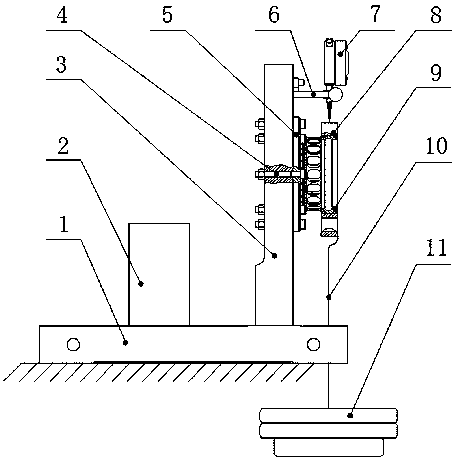

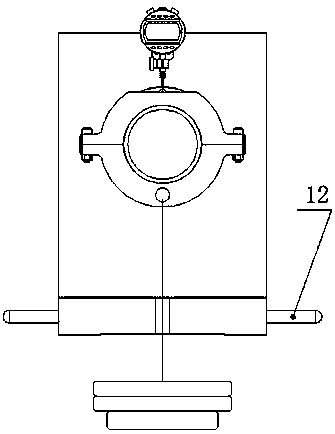

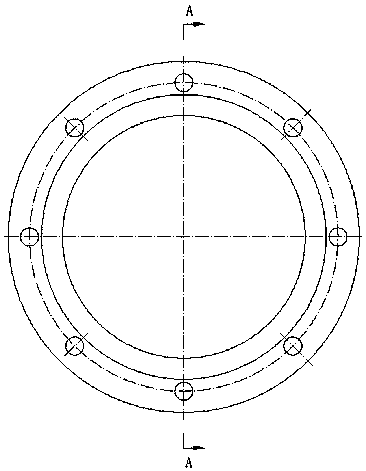

[0033] like figure 1 , figure 2 As shown, a detection device for radial stiffness of a bearing ring with an installation side, the detection device includes a base 1, a vertical plate 3 fixed on the base, a measuring table frame 6, a measuring table 7 and a load block 11; The positioning disc 5 used to fix the bearing ring on the vertical plate is fixed on the vertical plate 3; image 3 , Figure 4 , the positioning, the positioning disc 5 is an annular structure with a stepped through hole in the center; the smaller diameter d1 of the stepped through hole in the center of the positioning disc is greater than the outer diameter of the bearing ring, and smaller than the outer diameter of the bearing ring mounting side ; The larger diameter hole of the stepped through hole in the center of the positioning disc is used as the installation hole for installing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com