Workpiece collaborative machining method and system and collaborative control method and device

A technology of workpiece and workpiece coordinates, applied in the direction of digital control, electrical program control, etc., can solve the problems that it is difficult to realize the synchronous control movement of mechanical unit A, the difficulty of motion trajectory, and the difficulty of interpolation, so as to achieve low interpolation difficulty and synchronization The effect of improved control movement and simple movement trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

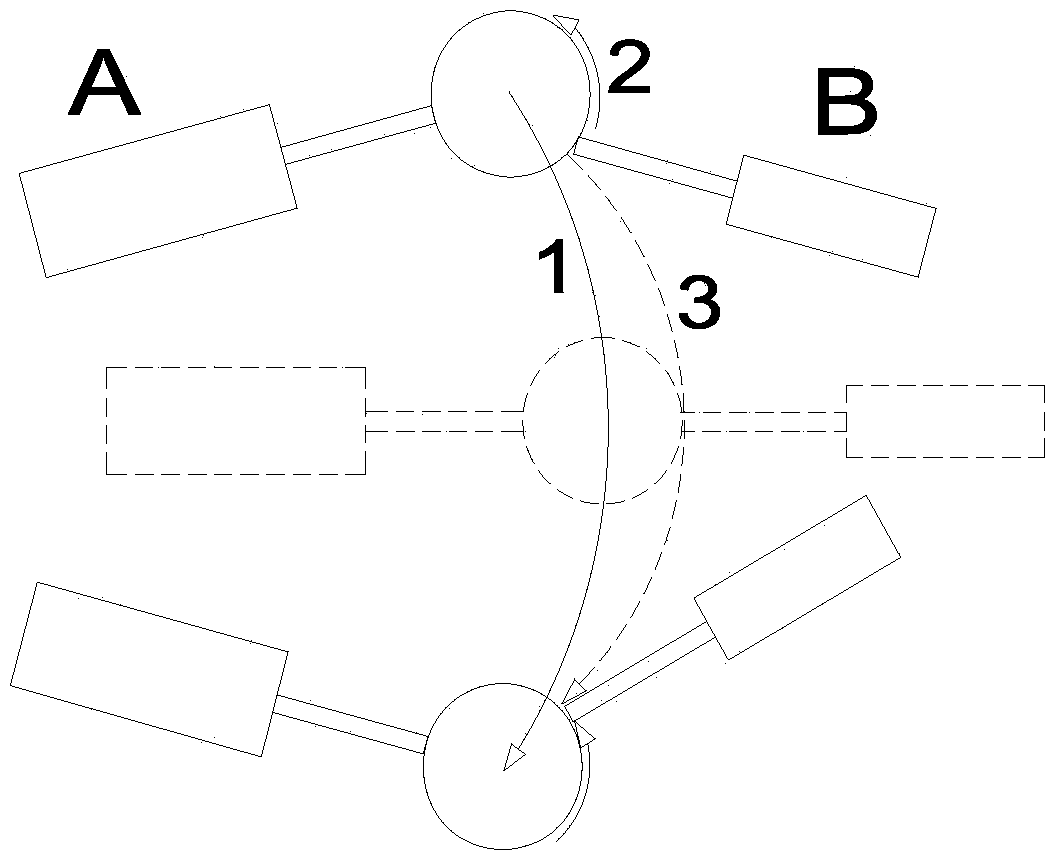

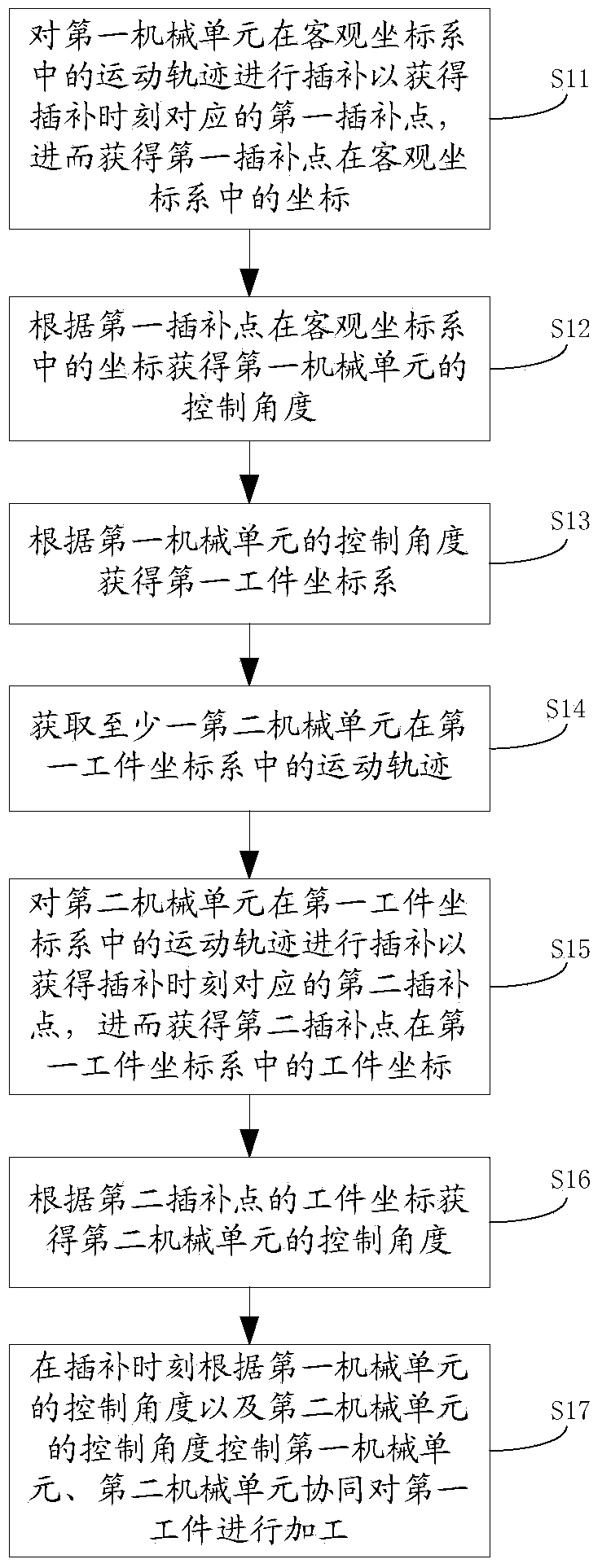

[0025] See figure 2 , The first embodiment of the collaborative processing method of the workpiece of the present invention includes:

[0026] Step S11: Interpolate the movement track of the first mechanical unit in the objective coordinate system to obtain the first interpolation point corresponding to the interpolation time, and then obtain the coordinates of the first interpolation point in the objective coordinate system.

[0027] Interpolate the motion track of the first mechanical unit in the objective coordinate system to obtain the first interpolation point corresponding to the interpolation time t, and then obtain the coordinates of the first interpolation point in the objective coordinate system. Interpolation is the process of obtaining the interpolation point located in the middle of the known point according to the interpolation algorithm according to some points on the motion trajectory. The interpolation point corresponding to the interpolation time t is the tool cen...

no. 2 approach

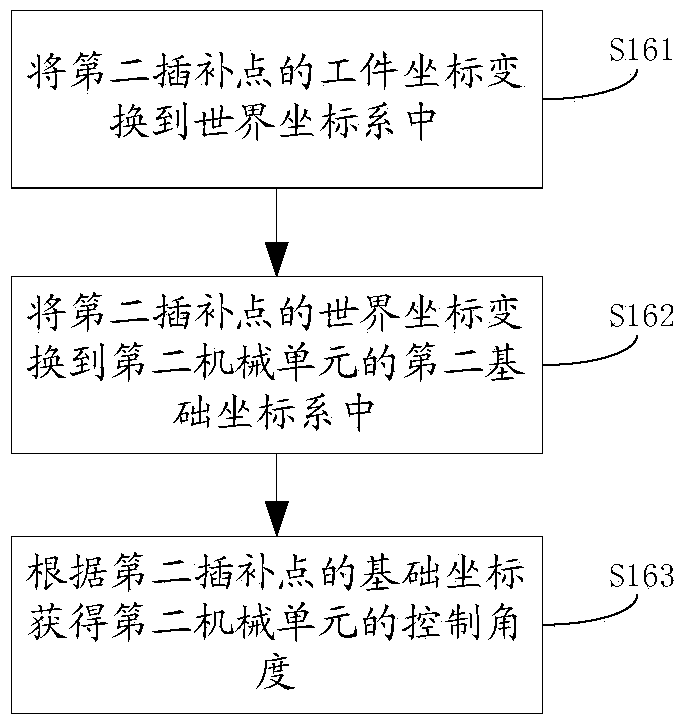

[0052] See Figure 4 , The second embodiment of the collaborative processing method of the workpiece of the present invention includes:

[0053] Step S21: Interpolate the movement track of the first mechanical unit in the objective coordinate system to obtain the first interpolation point corresponding to the interpolation time, and then obtain the coordinates of the first interpolation point in the objective coordinate system.

[0054] In this embodiment, the objective coordinate system is a coordinate system that is stationary with respect to the world coordinate system. Further, the coordinate system that is stationary with respect to the world coordinate system is specifically a workpiece coordinate system that is stationary with respect to the world coordinate system.

[0055] Step S22: Obtain the control angle of the first mechanical unit according to the coordinates of the first interpolation point in the objective coordinate system.

[0056] In this embodiment, the coordinates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com