Automatic placement machine

A placement machine, fully automatic technology, applied in the direction of electrical components, electrical components, electrical components to assemble printed circuits, etc., can solve the problems of high cost, low placement accuracy, complex structure, etc., achieve low cost, increase placement The effect of improving installation efficiency and simplifying motion trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

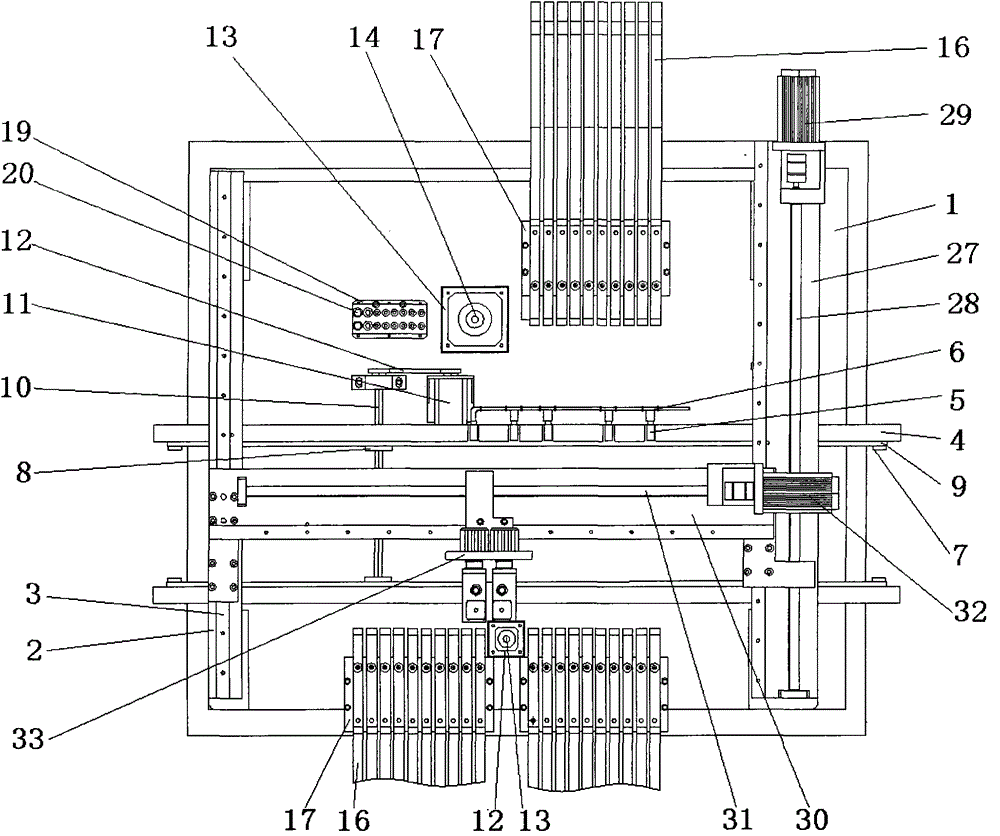

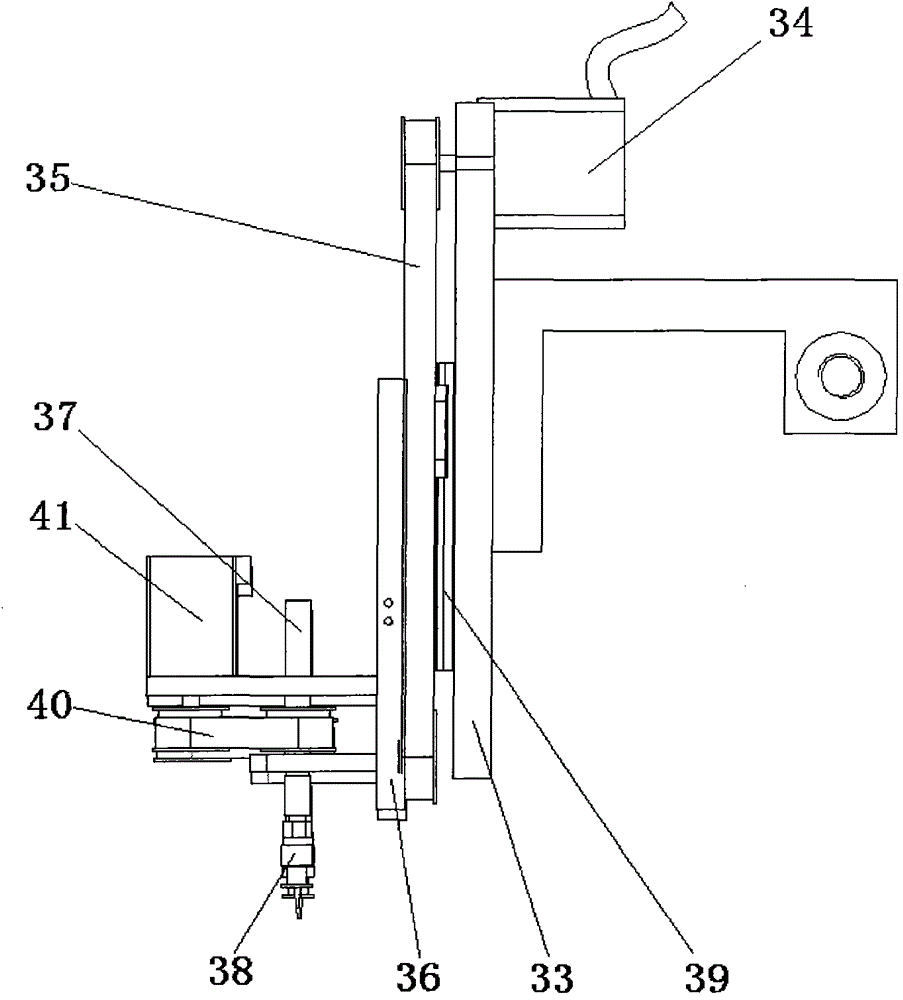

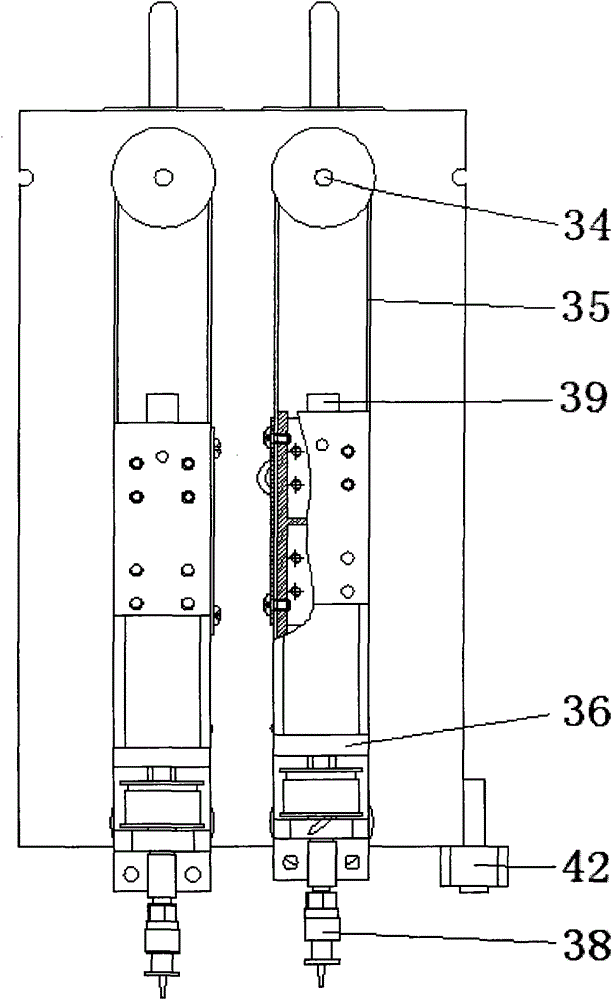

[0025] Such as figure 1 As shown, the fully automatic placement machine described in the embodiment of the present invention includes a base plate 1, and the two sides of the base plate 1 are symmetrically provided with a door-shaped base frame 2, and the upper end surface of the door-shaped base frame 2 on one side is fixedly connected to the second A linear slide rail 3, and the upper end surface of the door-shaped base frame 2 on the other side is fixedly connected with the first lead screw 28 device, the first lead screw 28 device is parallel to the first linear slide rail 3, and the first lead screw 28 device is parallel to the first linear slide rail 3, and the first lead screw 28 device A second lead screw 31 device is vertically arranged between the lead screw 28 device and the first linear slide rail 3, and the second lead screw 31 device is threadedly connected with a double-head placement mechanism, and the bottom of the door-shaped base frame 2 Vertically be provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com