Container closing apparatus

A sealing and container technology, applied in the directions of bottle/container cover, container closure with cover, packaging, etc., can solve the problems of easy wear, high acceleration, complex mechanical design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments will be described below with reference to the accompanying drawings. Identical, similar or identically acting components are identified here with the same reference numerals, and a repeated description of these components is sometimes omitted in the following description to avoid redundancy.

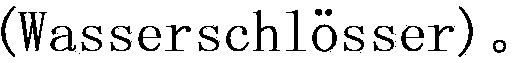

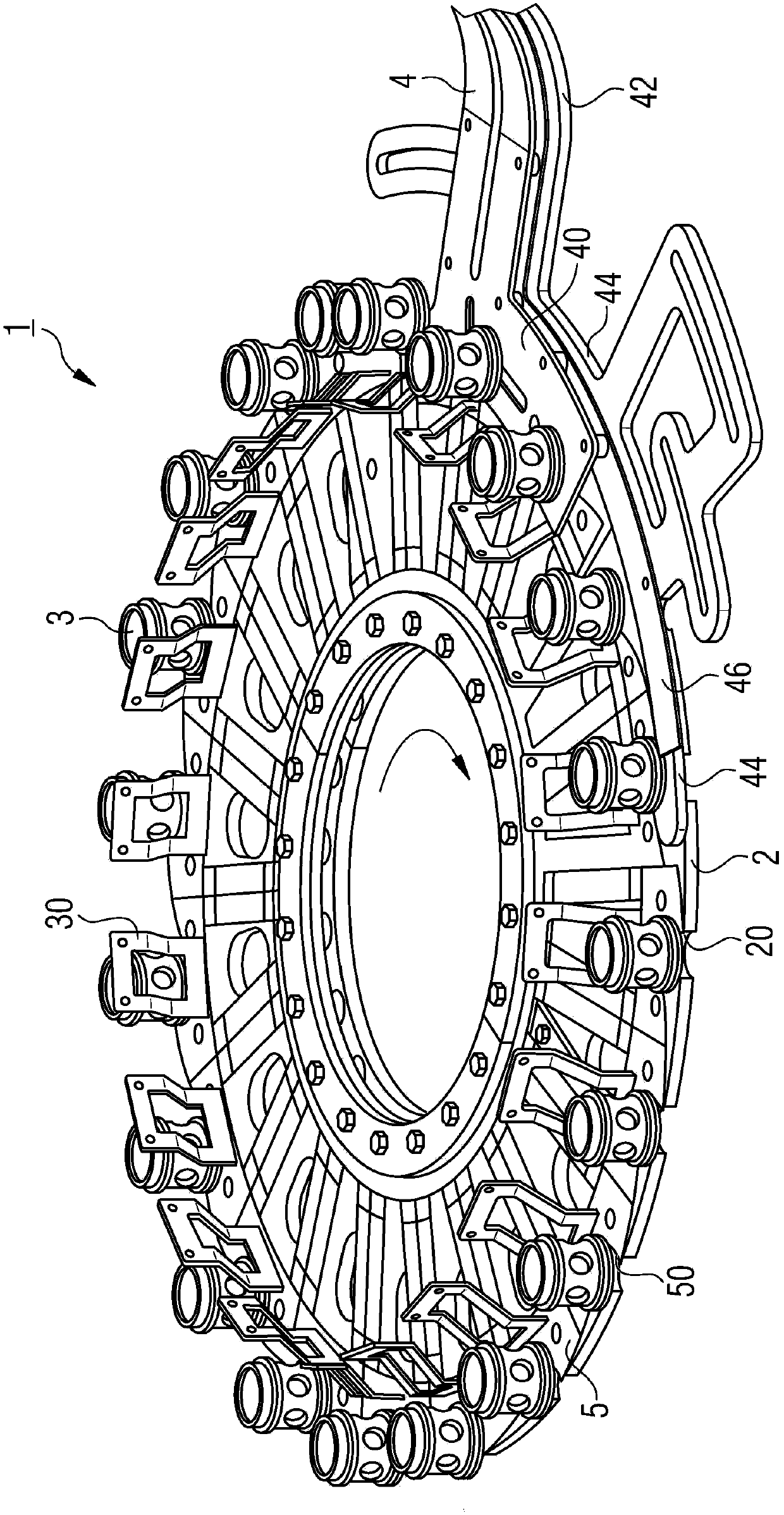

[0036] figure 1 A sealing machine 1 for closing containers with caps is schematically shown. A bottle neck guiding mechanism 2 is provided, which is used to guide the corresponding container, such as a PET bottle, at the bottle neck. In the embodiment shown, it is accordingly a so-called "bottleneck-operated" sealer. These containers are generally accommodated in the bottle neck guide 2 at this time, that is, the neck is accommodated in the recess 20 of the bottle neck guide 2 and then guided along the orbital movement specified by the movement trajectory of the bottle neck guide 2 . The bottle neck guide 2 is here in the form of a star wheel, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com