Method for putting hook in textile automatic packaging and hook adopting method

An automatic packaging and textile technology, applied in packaging and other directions, can solve the problems of a lot of labor, complex hooking mechanism, low success rate of hooking, etc., to simplify the movement trajectory, increase the packaging cost, and improve the overall packaging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

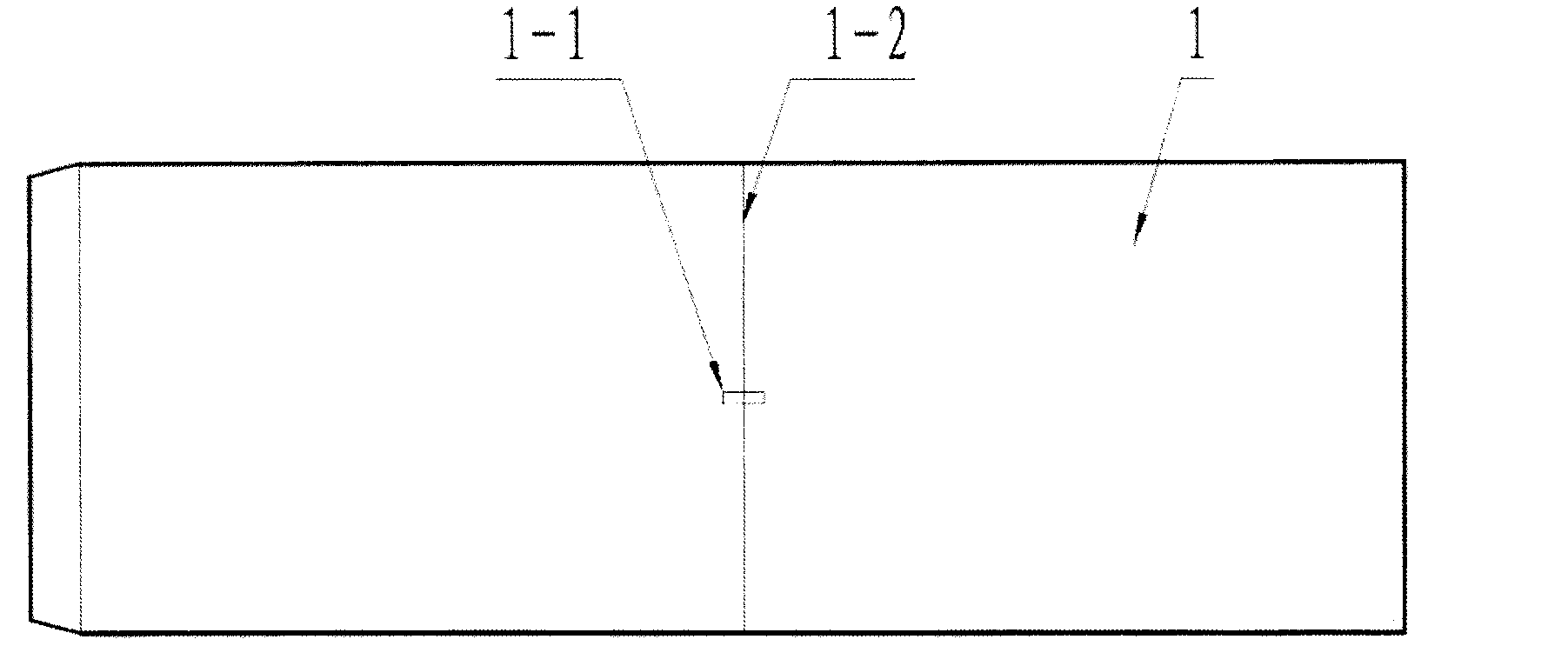

[0022] Such as figure 1 As shown, it is a schematic diagram of the packaging cardboard used for automatic packaging of textiles and its hook indentation provided by the present invention. The half-folded part of the packaging cardboard 1 is provided with a half-fold indentation 1-2, which is located in the center of the half-fold indentation 1-2. Fold the indentation 1-2 perpendicular to each other and make the rectangular hook indentation 1-1.

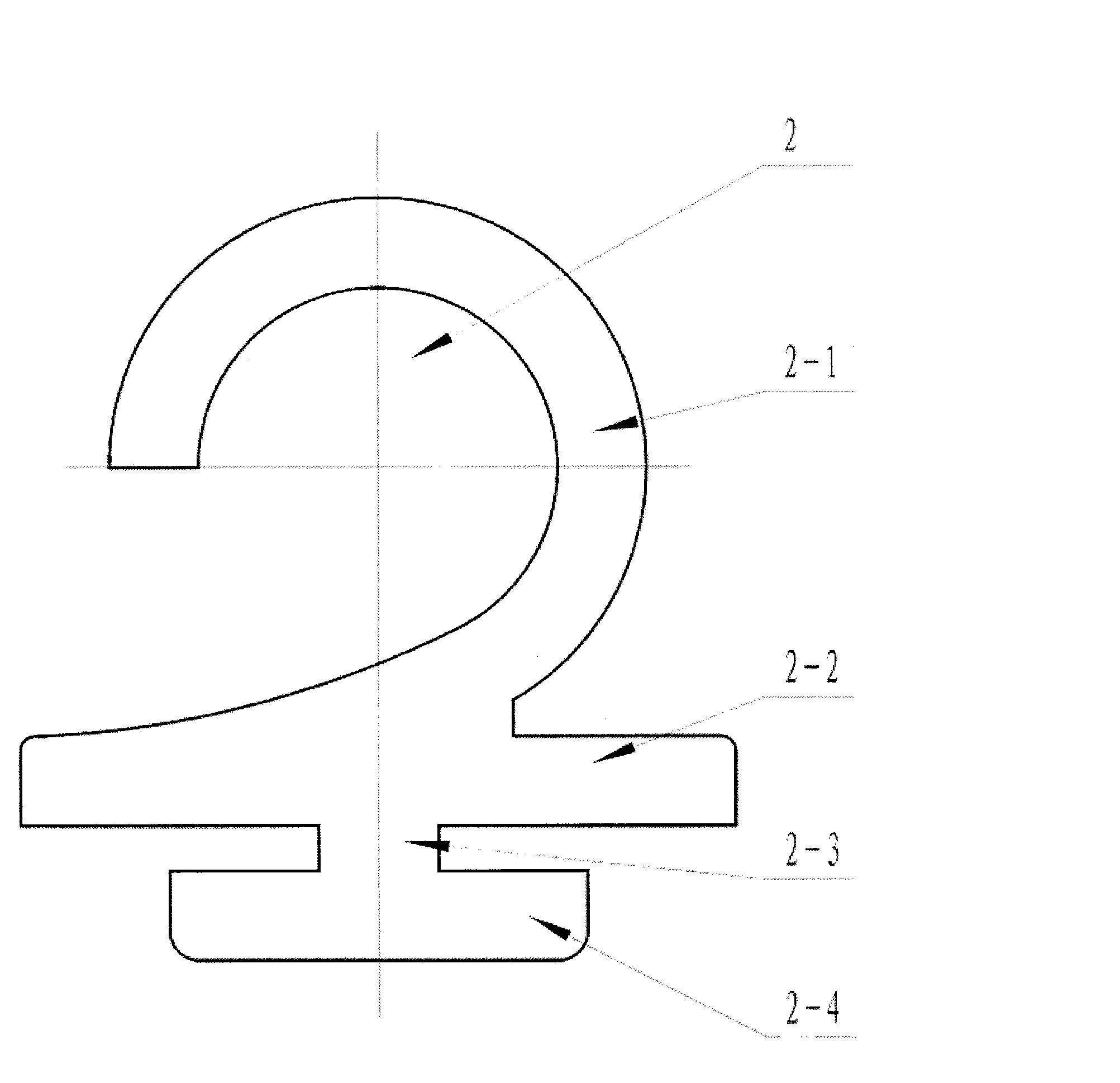

[0023] Such as figure 2 As shown, it is a schematic diagram of a hook for automatic packaging of textiles provided by the present invention, the hook 2 includes an upper hook 2-1 and an upper beam 2-2, the upper hook 2-1 is located on the upper beam 2-2, and the upper beam 2-2 The lower side of the lower beam is connected with the upper side of the lower beam 2-4 by the column 2-3, and the lower beam 2-4 is parallel to the upper beam 2-2. The length of the lower beam 2-4 matches the length of the rectangular hook indentation 1-1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com