Water-cooled TIG welding rotating arc sensor

A rotating arc and sensor technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as melting and evaporation, affecting weld quality, tungsten inclusion, etc., to facilitate welding, expand the application field, and reduce the quality of sensors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

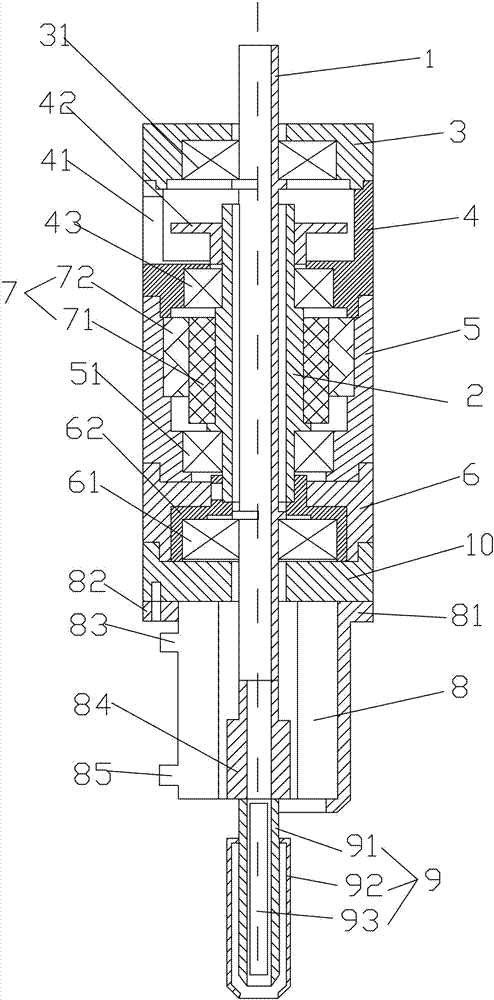

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

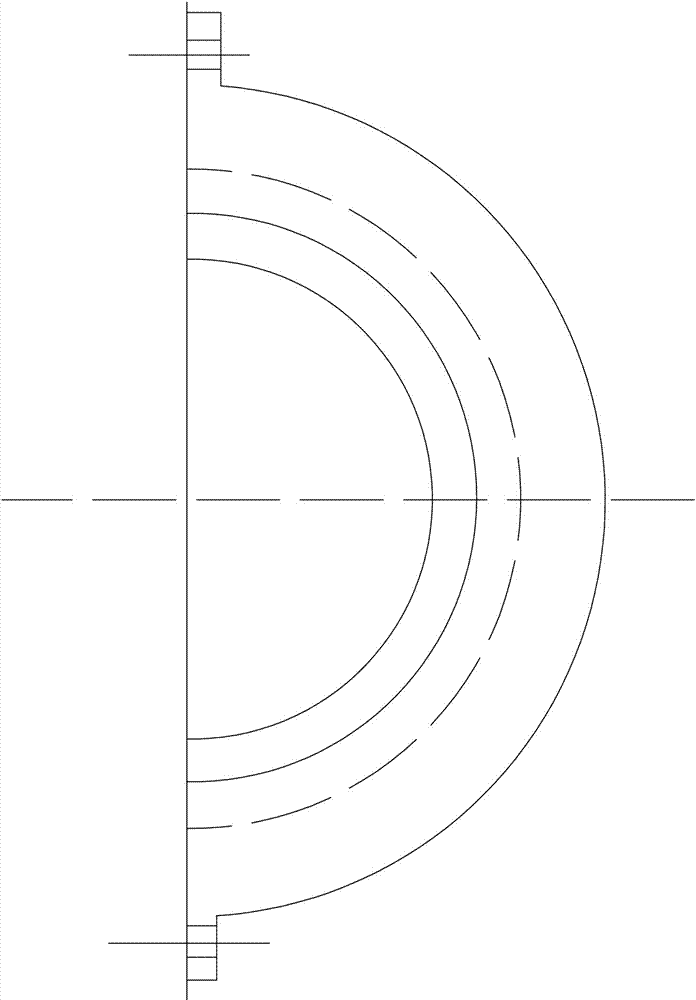

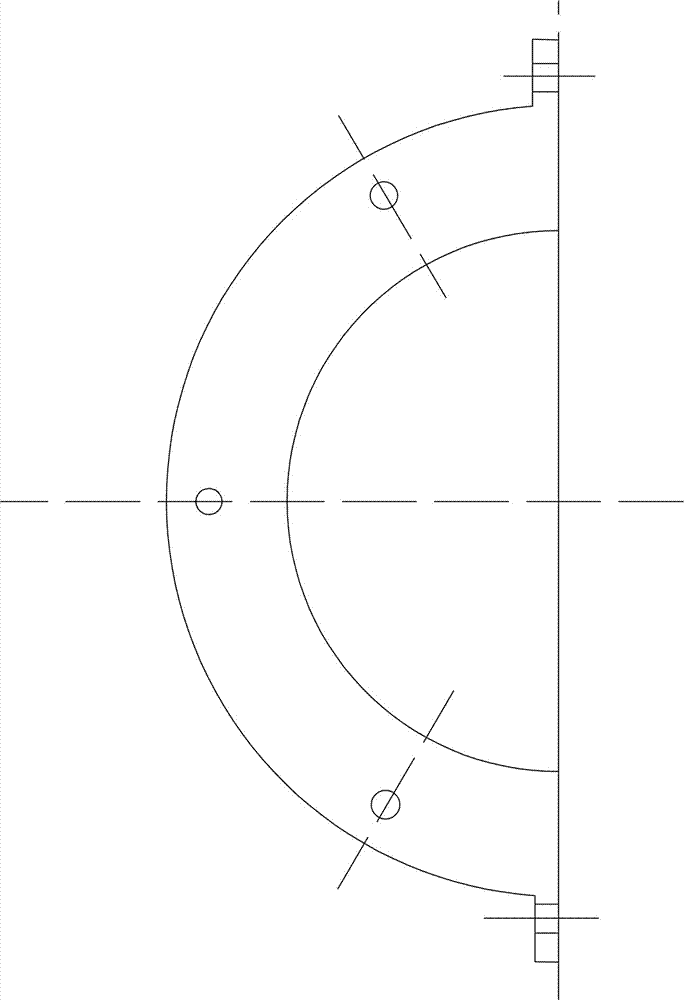

[0027] see Figure 1-4 .

[0028] The invention discloses a water-cooled TIG welding rotary arc sensor, which comprises an external casing and a hollow conductive rod 1 located in the casing, the casing is a hollow columnar cavity, and the conductive rod 1 runs through the top of the casing. , the lower surface, and the housing is sequentially arranged as an end cover 3, a speed measuring chamber 4, a power chamber 5, an eccentric chamber 6, and a bottom cover 10 from top to bottom. Shaft 2, a gap is provided between the hollow shaft 2 and the conductive rod 1, an optical code disc 42 and a photoelectric sensor 41 are arranged inside the speed measuring chamber 4, and the optical code disc 42 is tightly connected with the hollow shaft 2. In the embodiment, the optical code disc 42 and the hollow shaft 2 are fixed by screws, and the photoelectric sensor is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com