Cold-compression welding wire machine

A technology of cold-press welding and wire machine, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of welding electrode welding residue sticking, affecting product welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In one embodiment of the present invention, the welding electrodes in the cold wire welding machine are made of ceramic material. Due to the large difference in chemical structure between ceramic materials and metal materials, and the surface of ceramics is smooth, welding electrodes will not bond with welding residues such as welding residues of metal welding wires under normal circumstances, which will not affect the next welding. Significantly improve welding efficiency and welding quality.

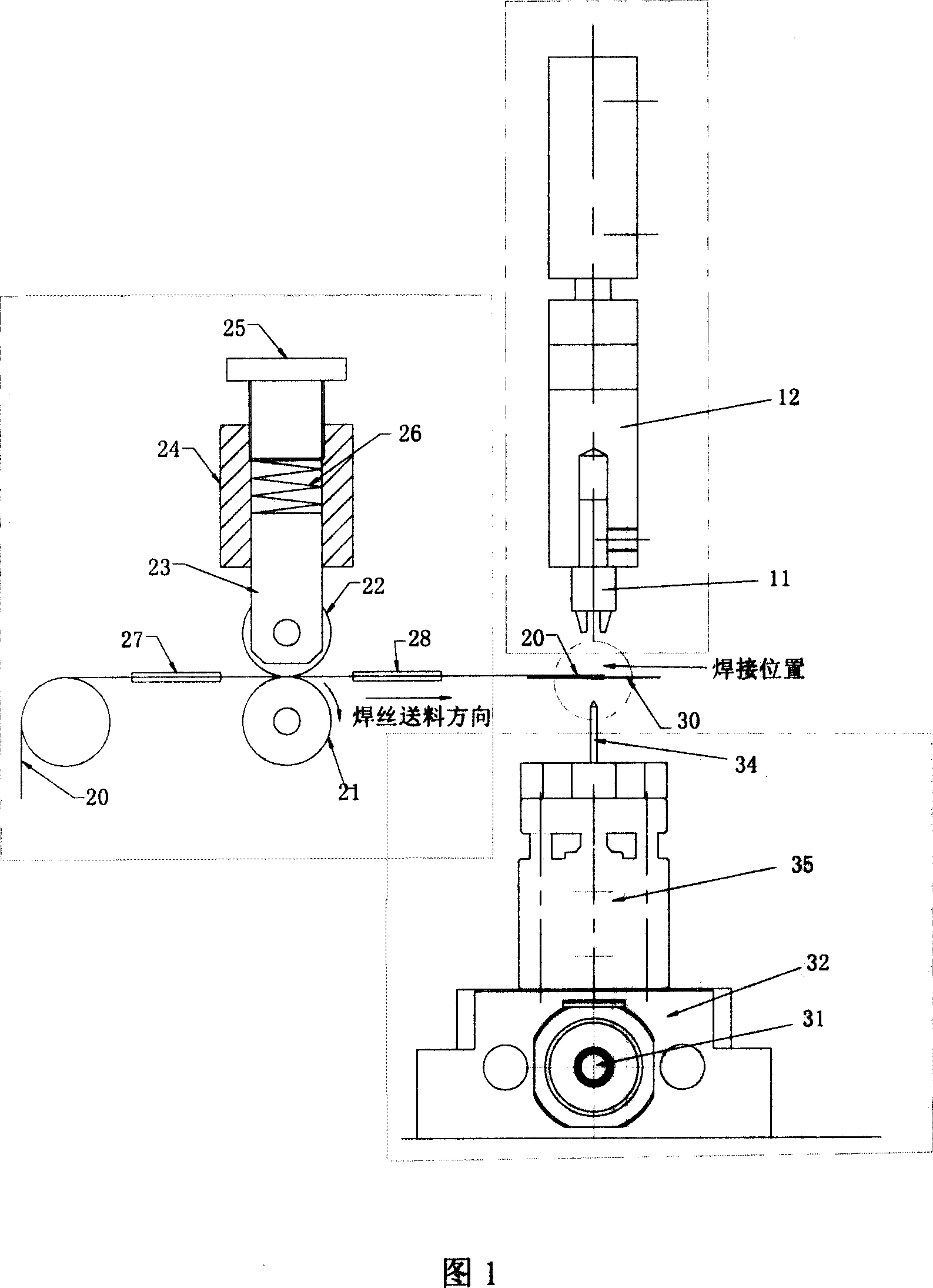

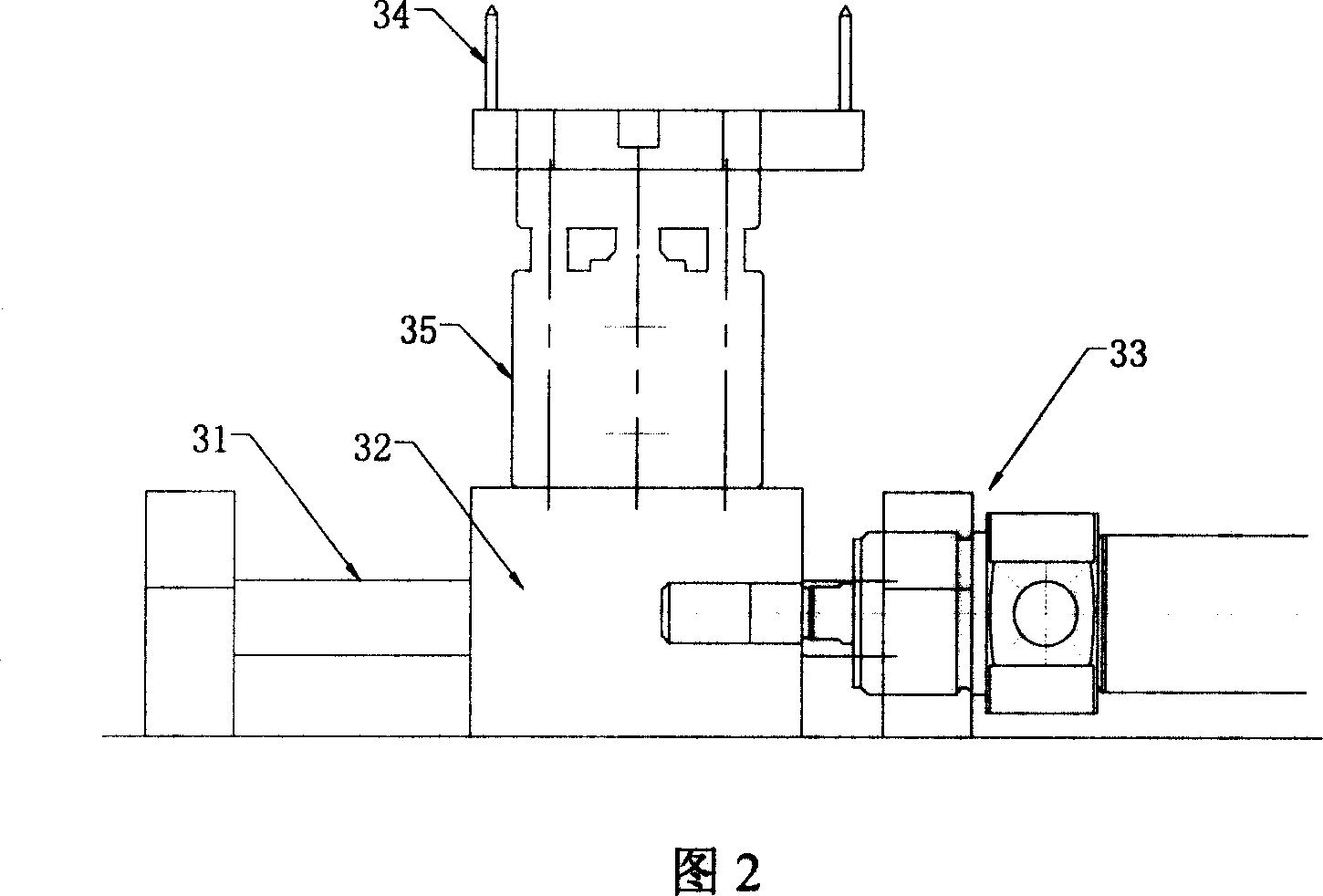

[0012] As shown in FIG. 1 , in the cold-pressed wire welding machine, the welding electrode 11 is usually fixed by the welding electrode fixing member 12 . In the prior art, the electrode holder 12 is usually also made of metal materials.

[0013] In the present invention, since the welding electrode 11 is made of ceramic material, the welding electrode holder 12 is also preferably made of ceramic material. The advantage is that the welding electrode and the welding electrode h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com