Method for controlling lateral displacement of submarine pipeline

A control method and technology for submarine pipelines, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as buckling of submarine pipelines, pipeline rupture, and large pipeline stress, so as to prevent buckling propagation and operate Simple procedure and harm reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

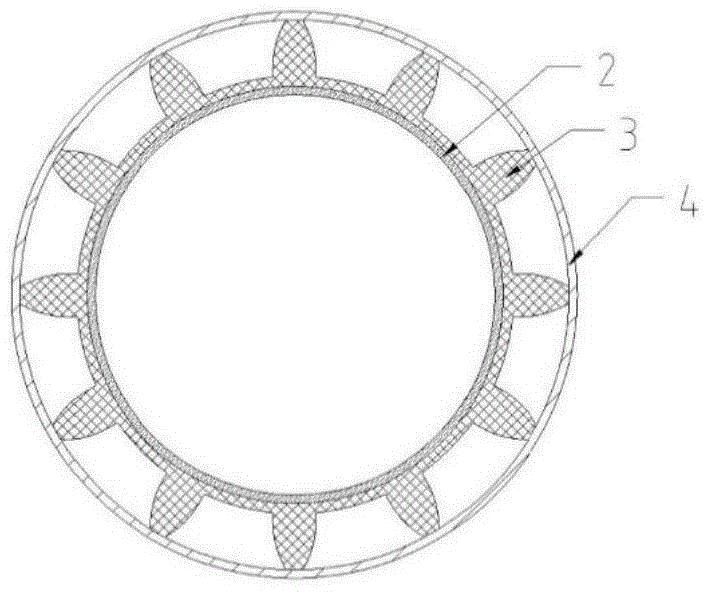

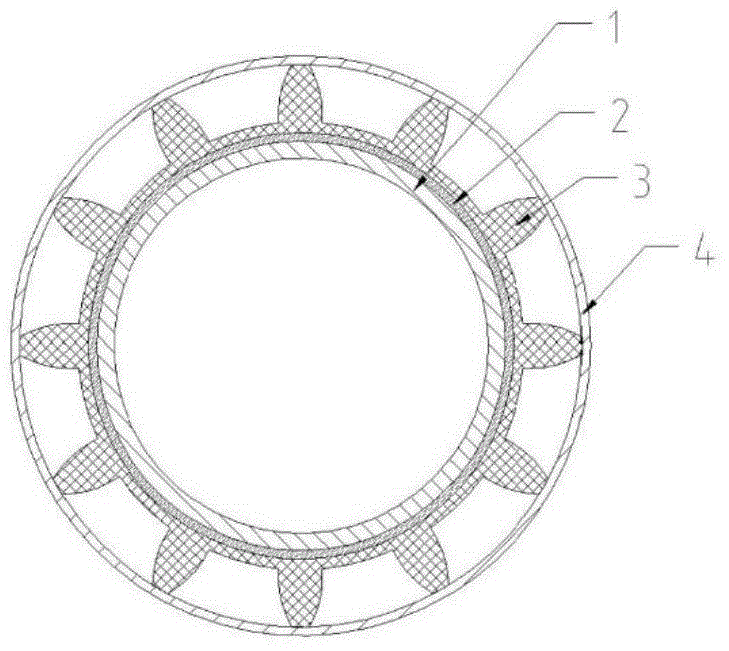

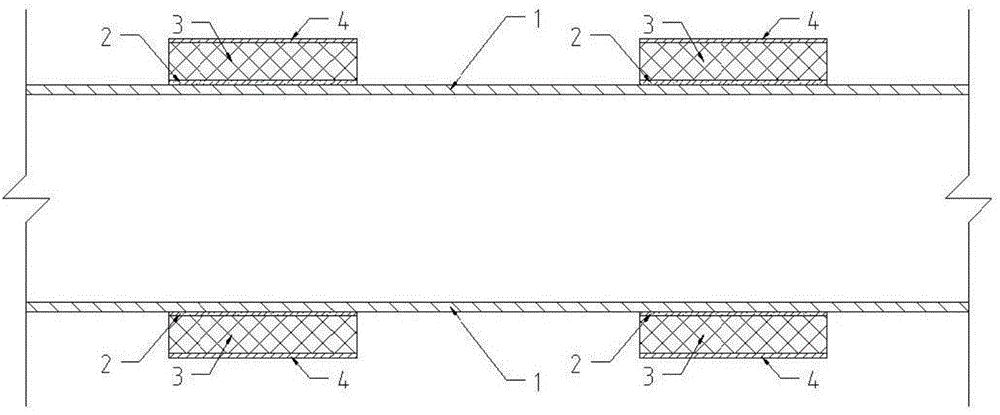

[0022] Attached below Figure 1-5 The present invention is described in detail with examples.

[0023] 1, the lateral displacement control device that the present invention adopts mainly comprises stress sensor 2, microprocessor chip, power supply, relay, sucker type electromagnet 5, several parts of protective layer structure 4.

[0024] 2. The stress sensor 2 includes a strain gauge, a microprocessor chip, a relay and a power supply. The stress sensor 2 uses high-precision resistance strain gauges, and the strain gauges are evenly distributed circumferentially on the outer surface of the pipeline 1 to measure the pipeline strain. The strain gauge converts the measured strain into a corresponding voltage signal, which is used as the input signal of the intermediate relay to control the closing and opening of the output circuit of the intermediate relay. The inner diameter of the stress sensor 2 is the same as the outer diameter of the pipeline 1, and the strain gauges are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com