High-nitrogen austenitic stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

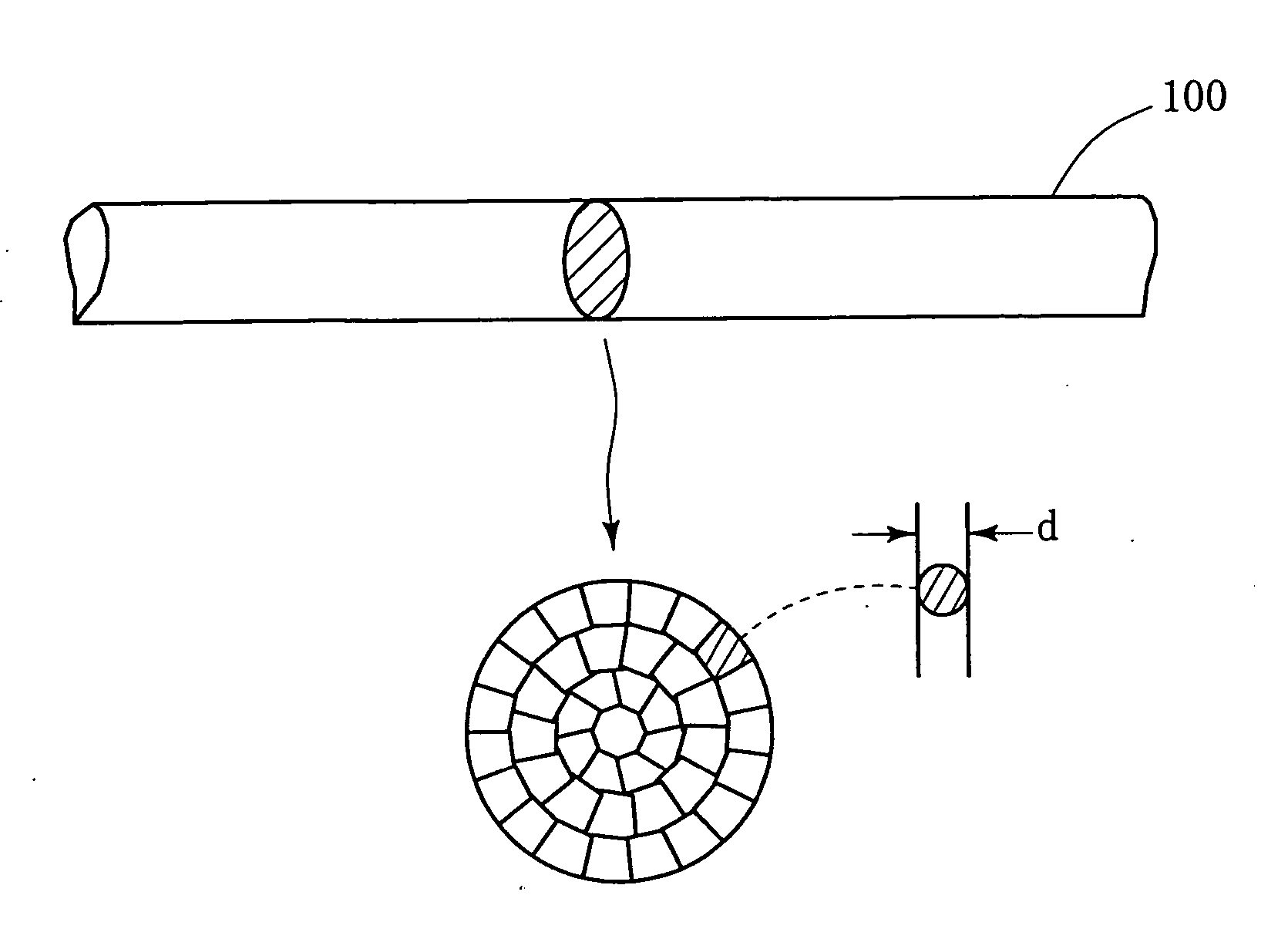

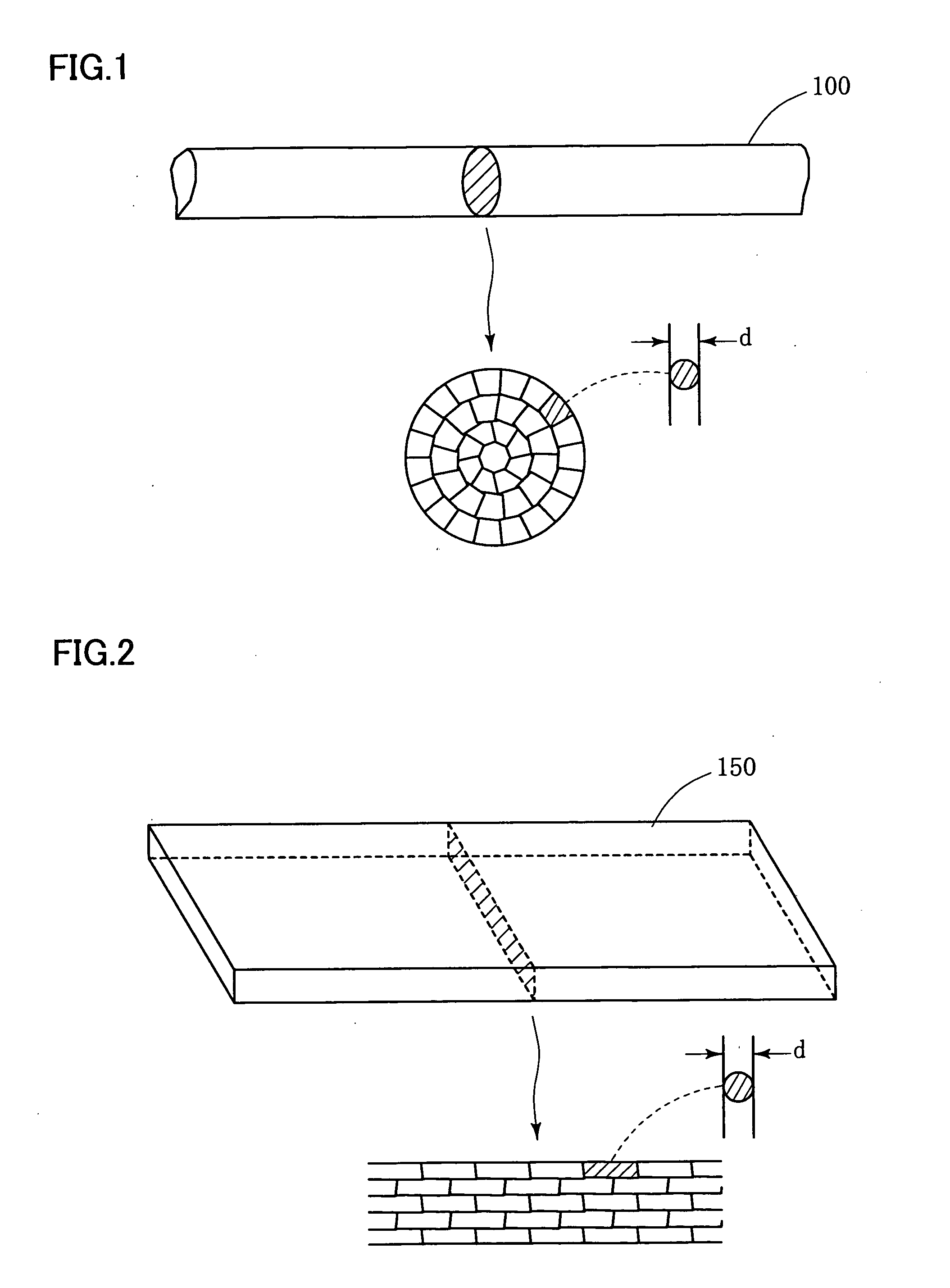

Image

Examples

Embodiment Construction

[0077]

CSiMnPSCuNiCrMoCoWVAlTiNbONExample 10.040.150.20.010.010.160.2130.01.000.150.200.0080.010.0021.38Example 20.030.201.50.020.010.050.2024.06.021.520.460.0070.050.0031.20Example 30.100.311.00.020.010.200.0127.01.870.0060.0021.05Example 40.030.507.00.010.010.510.1018.04.030.260.100.210.0060.090.040.0021.07Example 50.020.119.00.020.010.320.3026.02.500.980.480.0050.060.0021.33Example 60.030.192.00.020.010.160.2025.01.500.340.140.010.0060.0011.20Example 70.050.163.00.010.011.500.0826.02.010.130.0040.0030.84Example 80.030.221.50.020.010.160.0725.02.450.470.150.0050.0011.12Example 90.050.211.80.020.010.160.0925.10.100.200.020.0060.020.010.0031.17Example 100.060.201.50.020.010.970.0732.00.510.310.050.320.0050.150.050.0031.21Example 110.010.285.00.010.010.100.0928.00.540.290.160.120.0100.070.0020.98Example 120.030.012.00.020010.160.0328.40.520.150.010.0070.0051.22Example 130.030.201.80.020010.190.0226.01.990.0080.0011.14Comparative*0.310.244.00.010.010.140.3126.80.540.200.0060.0021.11Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com