High-toughness and corrosion-resistant aluminum alloy profile for aerospace and preparation method thereof

An aluminum alloy profile and aerospace technology, which is applied in the field of high toughness and corrosion-resistant aluminum alloy profiles for aerospace and its preparation, can solve the problem of high toughness and good corrosion resistance, which cannot meet high tensile strength at the same time, and cannot meet the requirements of aluminum alloy profiles. Meet the requirements of aerospace use and other issues, and achieve the effect of excellent corrosion resistance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

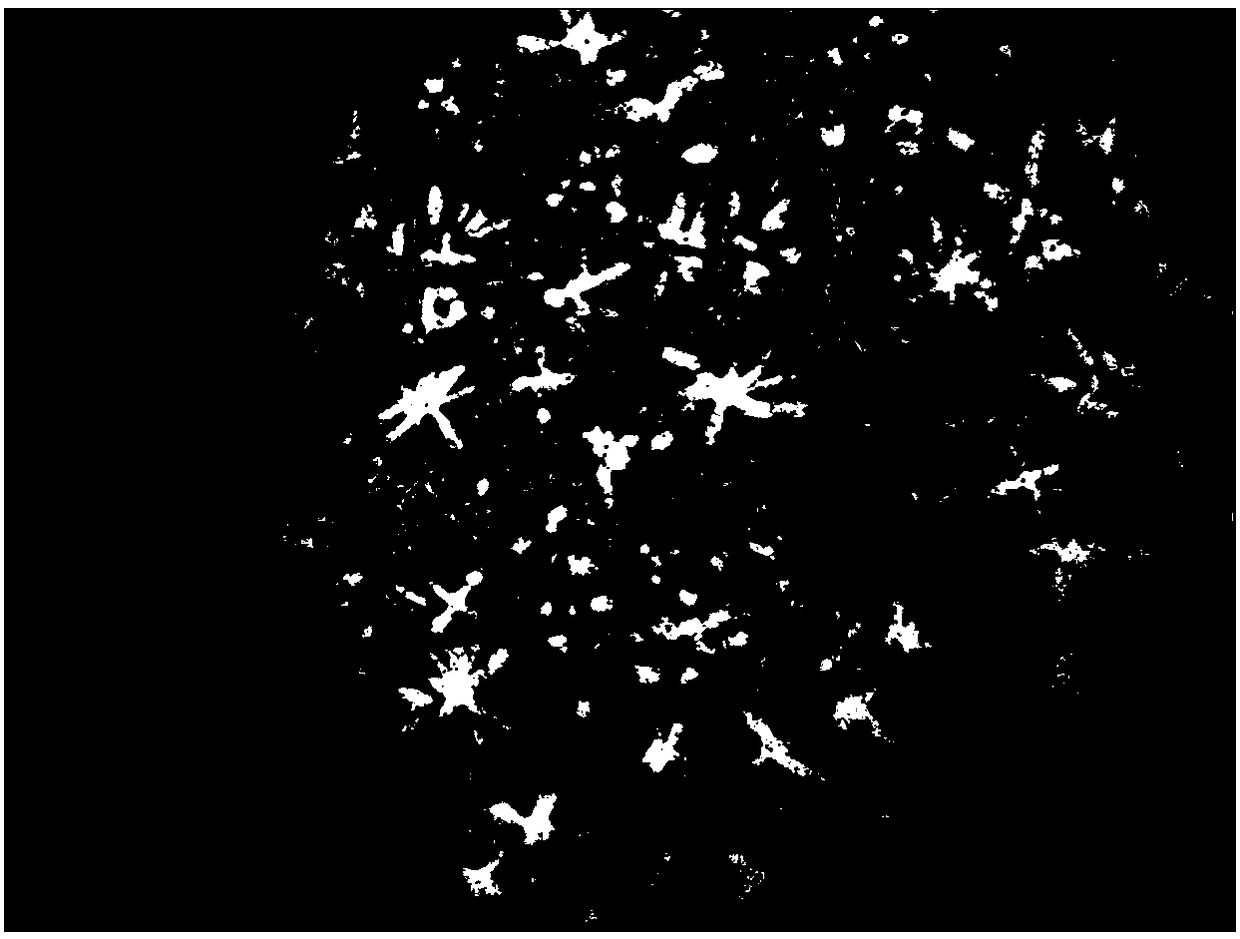

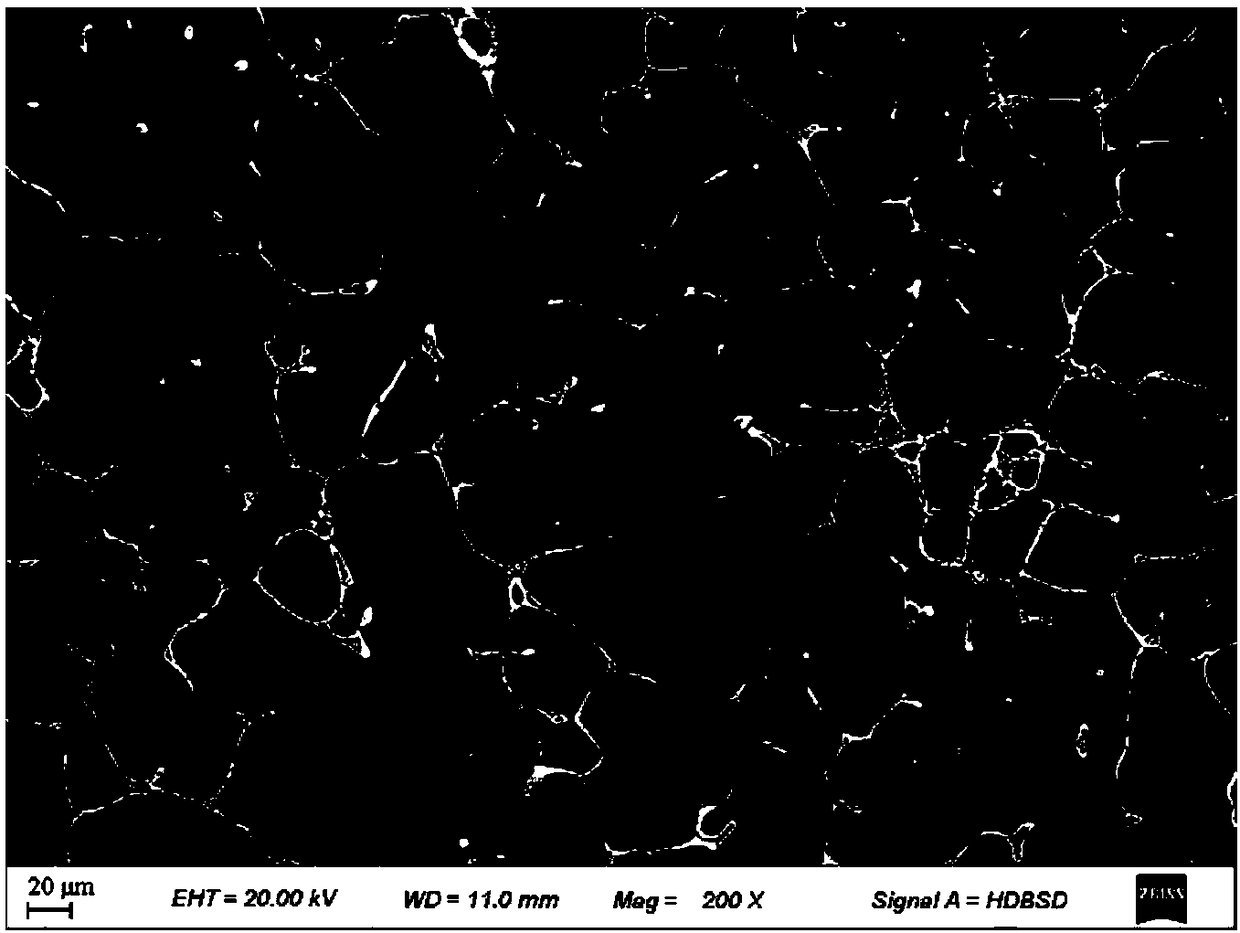

Image

Examples

specific Embodiment approach 1

[0040] Specific implementation mode 1: In this implementation mode, a high-toughness and corrosion-resistant aluminum alloy profile for aerospace is composed of Cu: 1.9% to 2.2%, Mg: 2.2% to 2.6%, and Zn: 9.2% to 9.8% by mass. %, Zr: 0.10% to 0.13%, and the balance is made of smelted raw materials of Al.

[0041] The impurity elements such as Fe and Si in this embodiment originate from aluminum ingots, and the impurities in the aluminum alloy profiles are Fe≤0.08%, Fe≤0.10%, and other single impurities≤0.05%. No effect.

[0042] The longitudinal tensile strength of the profiles manufactured in this embodiment is 670-682N / mm 2 ;Standard non-proportional extension strength 644-647N / mm 2 , the elongation after breaking is 11.3-13.9%; the compressive yield strength is 652-661MPa, and the fracture toughness of the profile tested according to GB / T 4161 is 33.2MPa m 1 / 2 , According to GB / T 12966-2008 test conductivity 37.2 ~ 38.2% IACS, according to HB5455 test exfoliation corrosi...

specific Embodiment approach 2

[0043] Specific embodiment two: In this embodiment, a method for preparing a high-toughness and corrosion-resistant aluminum alloy profile for aerospace is carried out according to the following steps:

[0044] 1. Aluminum alloy profiles are composed of elements with mass percentages of Cu: 1.9% to 2.2%, Mg: 2.2% to 2.6%, Zn: 9.2% to 9.8%, Zr: 0.10% to 0.13%, and the balance is Al Proportionally weigh aluminum ingots, cathode copper, primary magnesium ingots, zinc ingots, and aluminum-zirconium alloy ingots as raw materials, and then melt the raw materials in a melting furnace to obtain aluminum alloy melts;

[0045] 2. Casting the molten aluminum alloy obtained in step 1 into a round ingot;

[0046] 3. Remove the casting scale of the round ingot at room temperature to obtain an aluminum alloy round ingot from which the scale has been removed;

[0047] 4. Heat the aluminum alloy round ingot with the scale removed at a temperature of 420°C to 440°C for 12 hours, then heat it up ...

specific Embodiment approach 3

[0060] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that the aluminum alloy profiles are Cu: 2.0%, Mg: 2.5%, Zn: 9.6%, Zr: 0.12% and the balance according to the mass percentage of elements The proportion of Al is weighed and weighed to take aluminum ingots, cathode copper, primary magnesium ingots, zinc ingots, and aluminum-zirconium alloy ingots as raw materials. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal tensile strength | aaaaa | aaaaa |

| Non-proportional tensile strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com