High-strength high-toughness Al-Mg-Si-Cu wrought aluminum alloy and preparation method thereof

A deformed aluminum alloy, high-strength and high-toughness technology, applied in the field of high-strength and high-toughness Al-Mg-Si-Cu deformed aluminum alloy and its preparation, can solve the problems of inability to obtain strength value, lower mechanical properties, lower plasticity and toughness of materials, etc. , to achieve the effect of reducing size, improving performance, and increasing the percentage of subgrains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] High-strength and high-toughness Al-Mg-Si-Cu deformed aluminum alloy, the mass percentage of the composition is: Mg 0.6~1.5wt.%, Si 0.8~1.6wt.%, Cu 0.2~0.8wt.%, Mn 0.2~1.0 wt.%, Cr 0.1~0.4wt.%, Ti 0.01~0.1wt.%, Fe≤0.25wt.%, the sum of unavoidable impurities≤0.15wt.%, and the balance is Al.

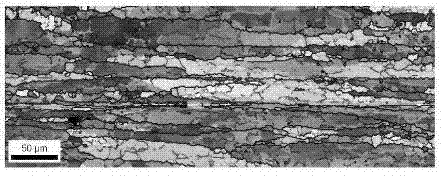

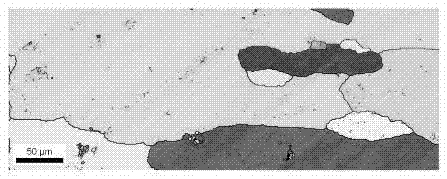

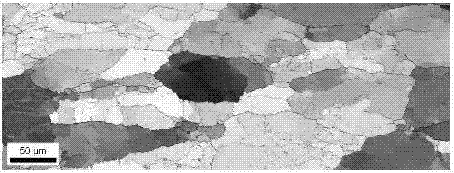

[0017] The preparation method of the high-strength and high-toughness Al-Mg-Si-Cu deformed aluminum alloy of the present invention, firstly, the alloy ingot is prepared by semi-continuous casting, and the composition content of Mg 0.6~1.5wt.%, Si 0.8~1.6 wt.%, Cu 0.2~0.8wt.%, Mn 0.2~1.0wt.%, Cr 0.1~0.4wt.%, Ti 0.01~0.1wt.%, Fe≤0.25wt.%, the sum of unavoidable impurities≤0.15 wt.%, the balance is Al; then homogenized, the ingot is heated to 520~570oC with the furnace in the circulating air furnace, kept for 4~10h, and air-cooled; then thermally processed and deformed, the ingot after homogenization treatment , thermal processing on thermal processing equipment, to ensure that the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com