Carbon fiber hybrid resin-base composite material foam sandwich structure and preparation technique thereof

A composite material, sandwich structure technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problems of easy damage, low elongation at break, etc., to save costs, improve impact resistance, Excellent effect of anti-corrosion and other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

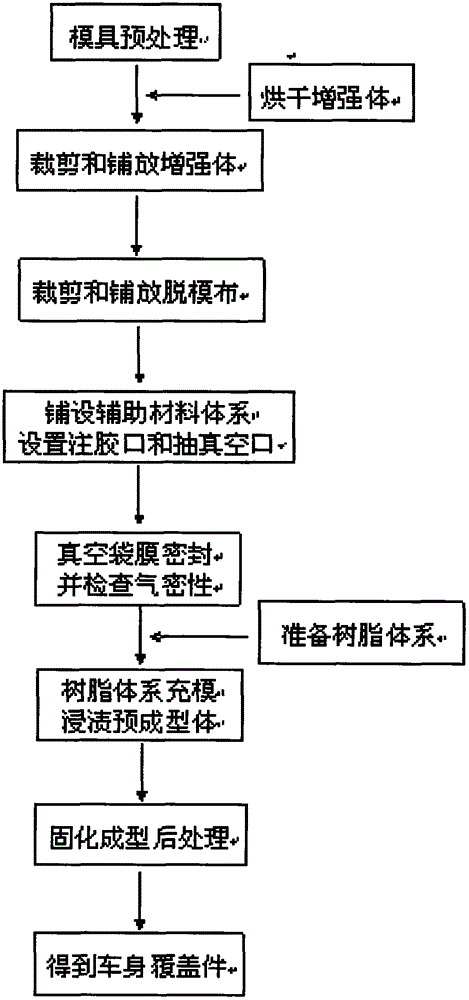

[0033] Preparation of carbon fiber and aramid fiber interlayer mixed form reinforced resin matrix composite sandwich structure automobile roof cover parts. Its preparation process flow chart is as follows figure 1 Shown:

[0034] 1. Mold pretreatment: Wipe the mold surface with alcohol, and then spray AXEL S-19C sealing agent and AXELX-807 release agent on the mold surface.

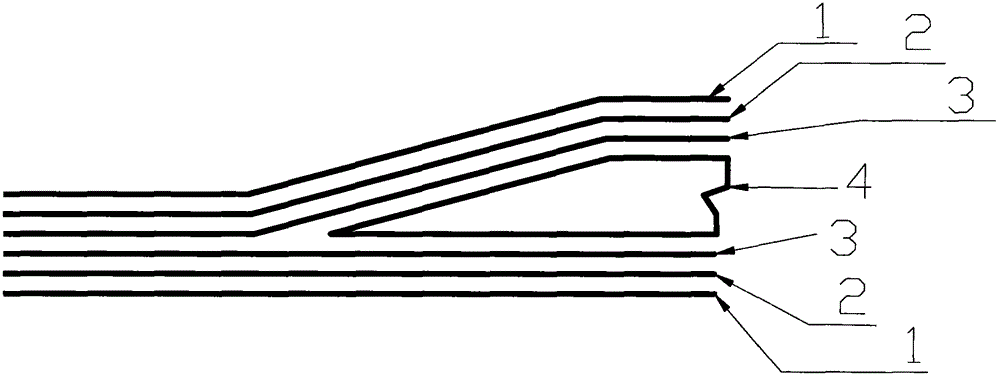

[0035] 2. Cutting and laying reinforcements: Cut 4 pieces of 3K carbon fiber cloth plain weave, 2 pieces of biaxial aramid fiber cloth and 1 piece of PMI sandwich material according to the surface size of the mold, and dry them in an oven; press figure 2 As shown, the reinforcement is laid on the mold to obtain a preform, and the laying sequence from top to bottom is carbon fiber cloth, aramid fiber cloth, carbon fiber cloth, PMI sandwich, carbon fiber cloth, aramid fiber cloth, carbon fiber cloth.

[0036] 3. Cutting and covering the release cloth: Lay the cut R85PA66 release cloth on the surface of t...

Embodiment 2

[0043] Preparation of carbon fiber and aramid fiber layers mixed in the form of reinforced resin-based composite foam sandwich structure automobile door parts, the process flow chart is as follows figure 1 Shown:

[0044] The 1st step is identical with specific embodiment 1.

[0045] 2. Cutting and laying reinforcements: Cut six pieces of mixed carbon / aramid fiber cloth according to the surface size of the mold, and dry them in an oven; lay them on the mold in turn to obtain a preform, and then Lay PVC foam sandwich on the third layer of fiber cloth.

[0046] The 3rd, 4th, 5th steps are identical with specific embodiment 1.

[0047]6. Resin system filling and impregnating the preform: open the injection port, stir the unsaturated polyester resin system that has been vacuumed and degassed, and use vacuum negative pressure to inject the mold cavity to impregnate the above preform, etc. After the preform is completely impregnated, close the injection port, and continue to vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com