Nickel titanium memory alloy/polyurethane compound damping panel and preparation method thereof

A nickel-titanium memory alloy and composite damping technology, applied in chemical instruments and methods, sound-producing instruments, instruments, etc., can solve the problems of poor damping effect, poor corrosion resistance, low tensile strength, etc., and achieve low cost and corrosion resistance. Good, wear-resistant and corrosion-resistant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment 1: A nickel-titanium memory alloy / polyurethane composite damping plate in this embodiment is characterized in that a nickel-titanium memory alloy / polyurethane composite damping plate adopts a three-layer composite structure, consisting of an upper surface layer, a lower surface layer and a middle layer. The damping layer is pressed; the upper surface and the lower surface are nickel-titanium memory alloy plates, and the damping layer is polyurethane plates.

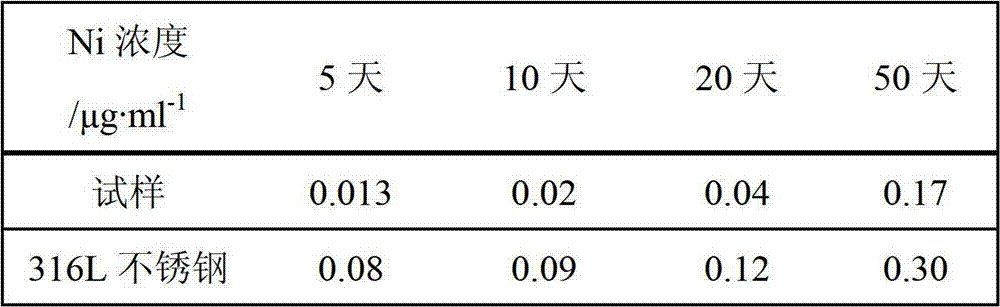

[0012] A nickel-titanium memory alloy / polyurethane composite damping plate in this embodiment adopts a three-layer composite structure, including an upper surface layer, a lower surface layer and a middle damping layer, and the upper surface layer and the lower surface layer are nickel-titanium memory alloy plates, which have high strength and hardness. And the wear resistance and corrosion resistance are better than ordinary metal materials. The middle damping layer is made of elastic polyuretha...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass fraction of nickel in the nickel-titanium memory alloy sheet material of the upper surface layer and the lower surface layer is 50.7% ~ 51%, the thickness range of the sheet material is 0.2 ~ 1mm, other steps The parameters are the same as in the first embodiment.

specific Embodiment approach 3

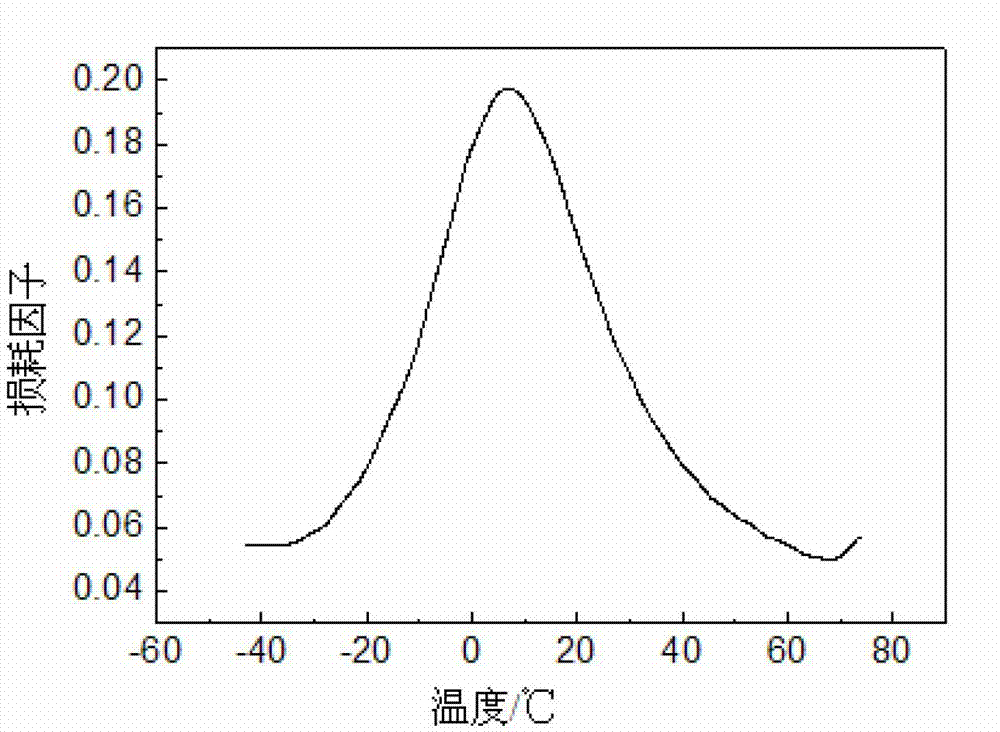

[0014] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the polyurethane plate of the damping layer has a glass transition temperature of -43~-47°C, a processing temperature of 180~195°C, and a thickness range of 0.1~2mm, other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com