Variable coupling of high pressure rotor and low pressure rotor of turbofan engine

一种涡扇发动机、高压转子的技术,应用在发动机元件、发动机功能、机器/发动机等方向,能够解决大发电机、不实际等问题,达到电力工作频率合适、尺寸合适、大容量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

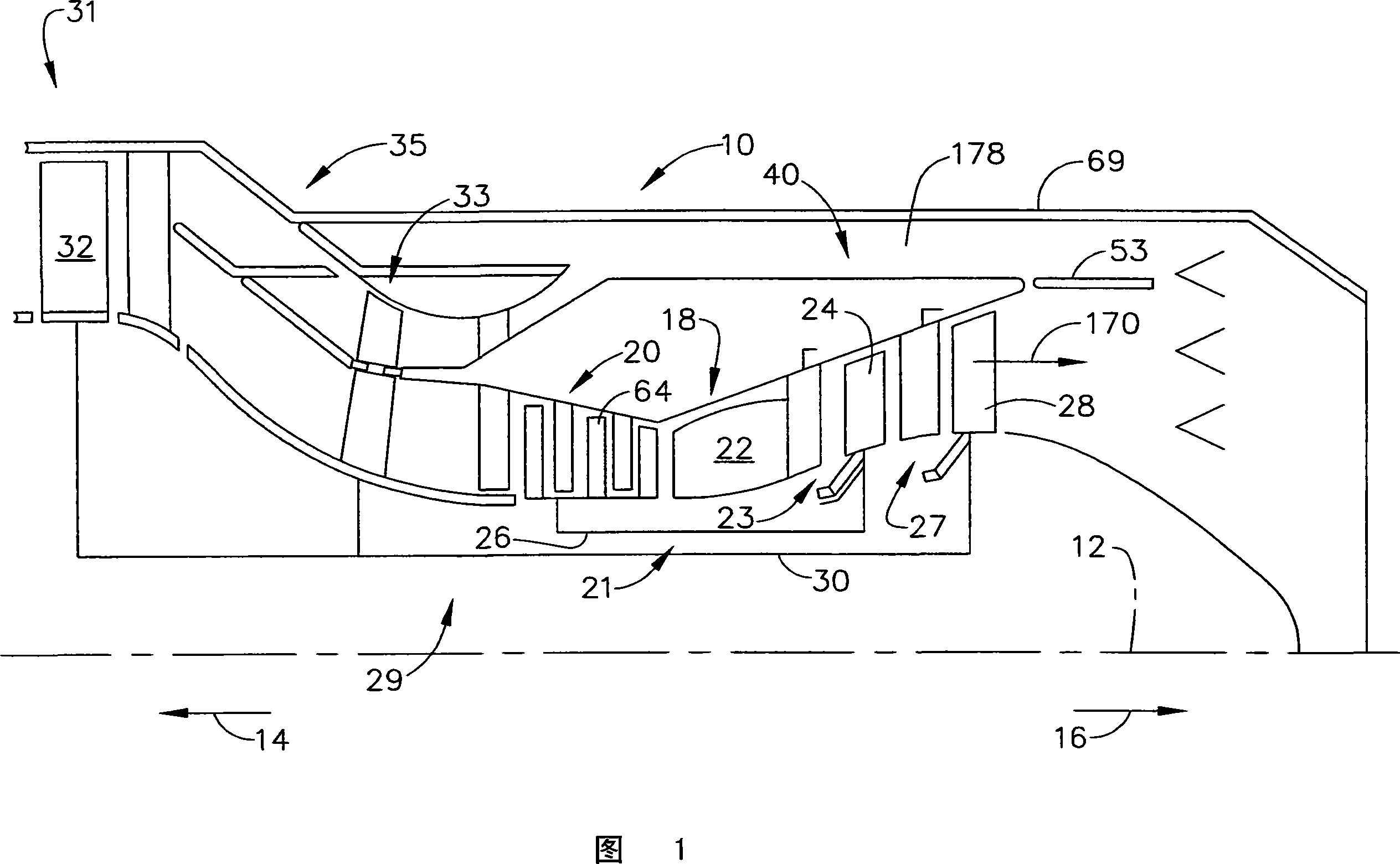

[0025] Shown in FIG. 1 is an exemplary turbofan engine 10 having a generally axially extending axis or centerline 12 extending generally in a forward direction 14 and an aft direction 16 . The ducted turbofan engine 10 includes a core engine 18 (also referred to as a gas generator) including a high pressure compressor 20, a combustor 22, and a high pressure turbine (HPT) 23 having a row of high pressure turbine blades 24, All arranged in series, axial flow relationship. High pressure compressor blades 64 of high pressure compressor 20 are fixedly connected in driving engagement to high pressure turbine blades 24 by a larger diameter annular core motor shaft 26 coaxially disposed about centerline 12 of engine 10 to create high pressure rotor 21.

[0026] A combustor 22 in the core engine 18 mixes pressurized air from the high pressure compressor 20 with fuel and ignites the resulting fuel and air mixture to produce combustion gases. Some work is extracted from these gases by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com