Polytetrafluoroethylene composite material and preparation method thereof

A polytetrafluoroethylene and composite material technology, which is applied in the field of polytetrafluoroethylene composite materials and its production, can solve the problems of poor wear resistance, low wear rate and friction coefficient, and achieves improved mechanical properties and wear resistance. Effects of friction coefficient, good mechanical properties and wear resistance

Inactive Publication Date: 2012-10-10

HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the properties of the existing PTFE composite materials are constantly being improved, the wear resistance of the existing PTFE composite materials is still poor, and it c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

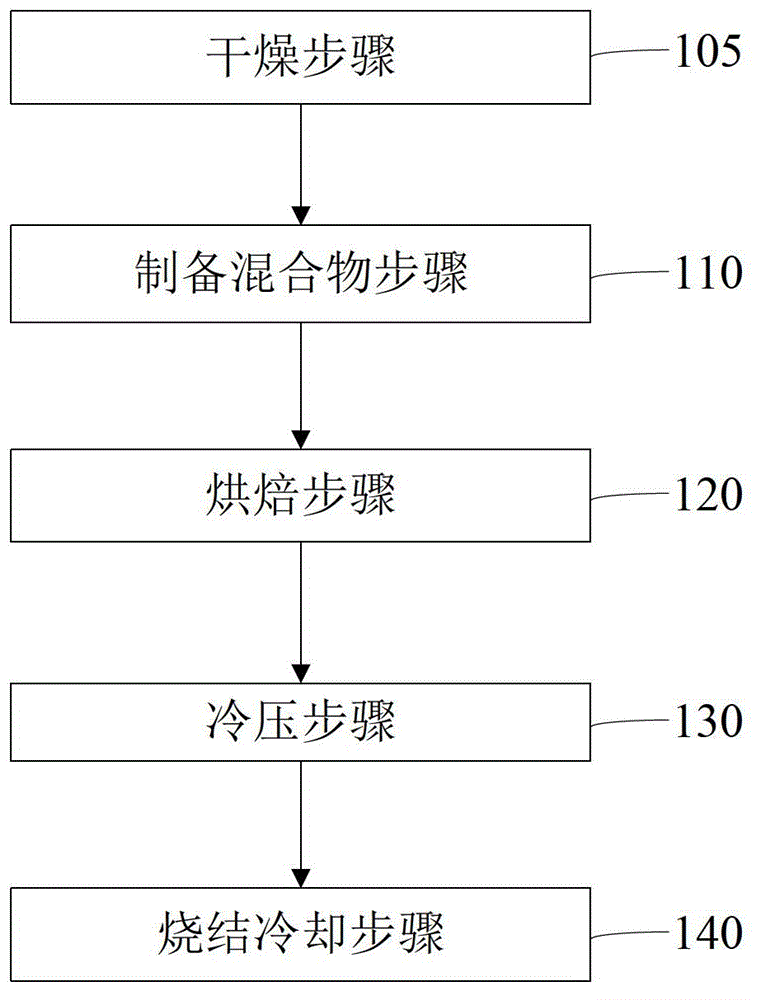

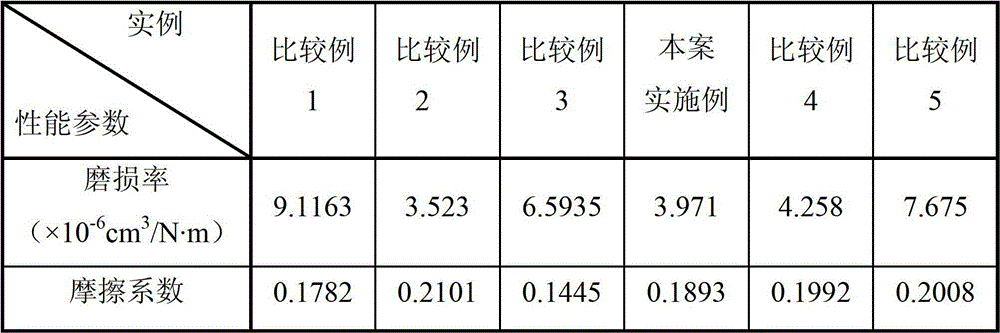

A polytetrafluoroethylene composite material is prepared by steps of mixing polytetrafluoroethylene powders, polyimide powders and graphite powders to prepare a mixture and subjecting the mixture to baking, cold pressing, sintering and cooling. The prepared polytetrafluoroethylene composite material comprises polytetrafluoroethylene, polyimide and graphite, wherein the mass percent of the polytetrafluoroethylene is between 65% and 75%, the mass percent of the polyimide is between 17% and 22%, and the mass percent of the graphite is between 7% and 13%. The polytetrafluoroethylene composite material has low friction coefficient and wear rate so that the mechanical property and abrasion resistance are improved.

Description

Technical field [0001] The invention relates to a polytetrafluoroethylene composite material, in particular to a polytetrafluoroethylene composite material with low friction coefficient and wear rate and a manufacturing method thereof. Background technique [0002] Polytetrafluoroethylene (PTFE) is a highly crystalline polymer of tetrafluoroethylene monomer. It is a white waxy thermoplastic with high temperature resistance, good chemical properties, low friction coefficient and good dielectric properties. These advantages make polytetrafluoroethylene widely used. However, PTFE also has many disadvantages, such as poor mechanical properties, large linear expansion coefficient, large molding shrinkage, difficult secondary processing, low hardness, easy wear, large friction coefficient, and creep resistance. Poor, easy to cold flow and so on. In order to improve and overcome the defects of pure PTFE, people have been working on the modification of PTFE to obtain PTFE composit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/18C08L79/08C08K3/04

Inventor 宋伟马芳武赵福全

Owner HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com