Automobile anti-sideslip hinge

An anti-skid and hinge technology, applied in anti-skid devices, motor vehicles, road vehicles, etc., can solve the problems affecting the service life of anti-skid chains, poor mechanical properties of nylon, etc., and achieve improved service life, good mechanical properties and wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

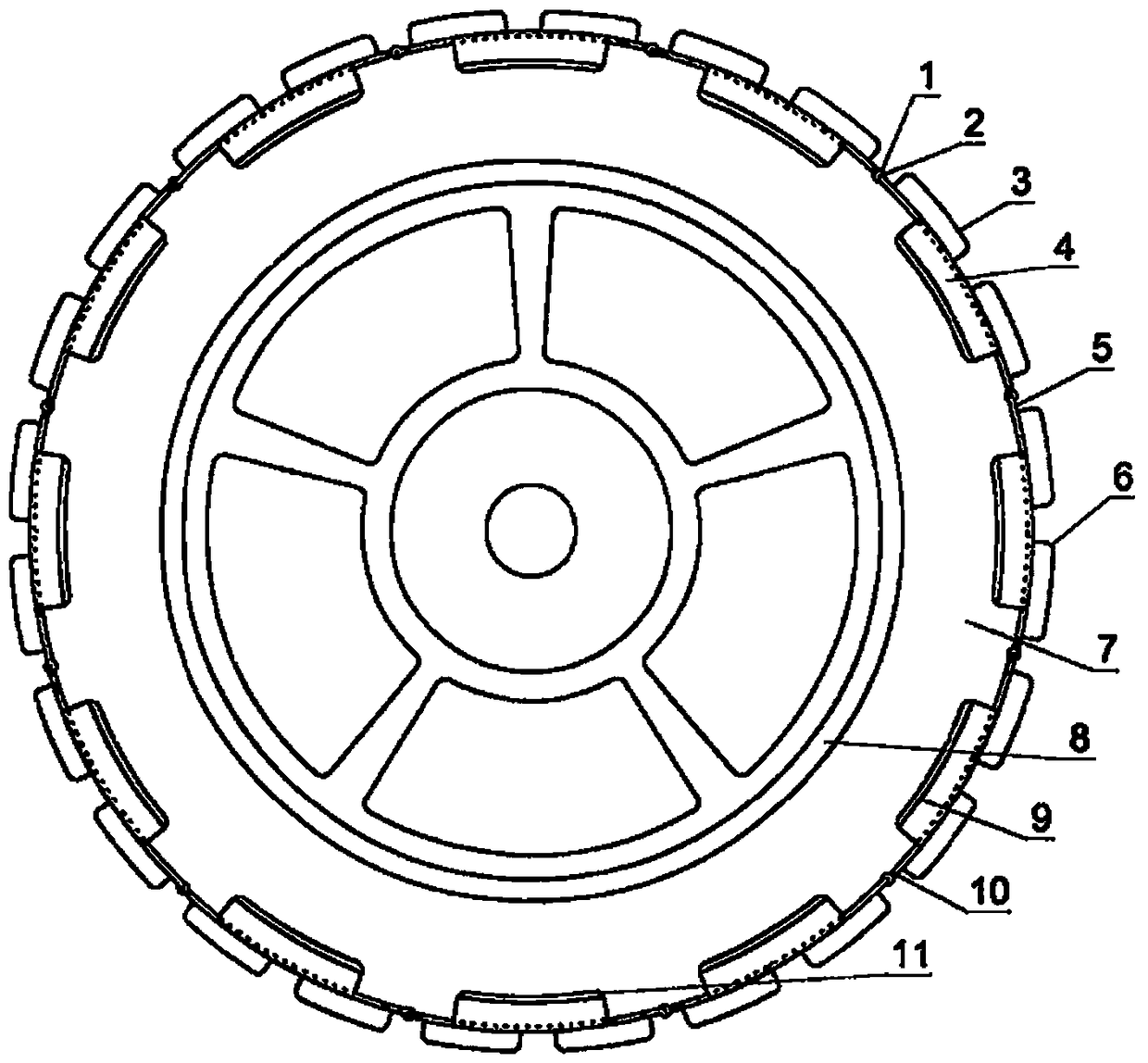

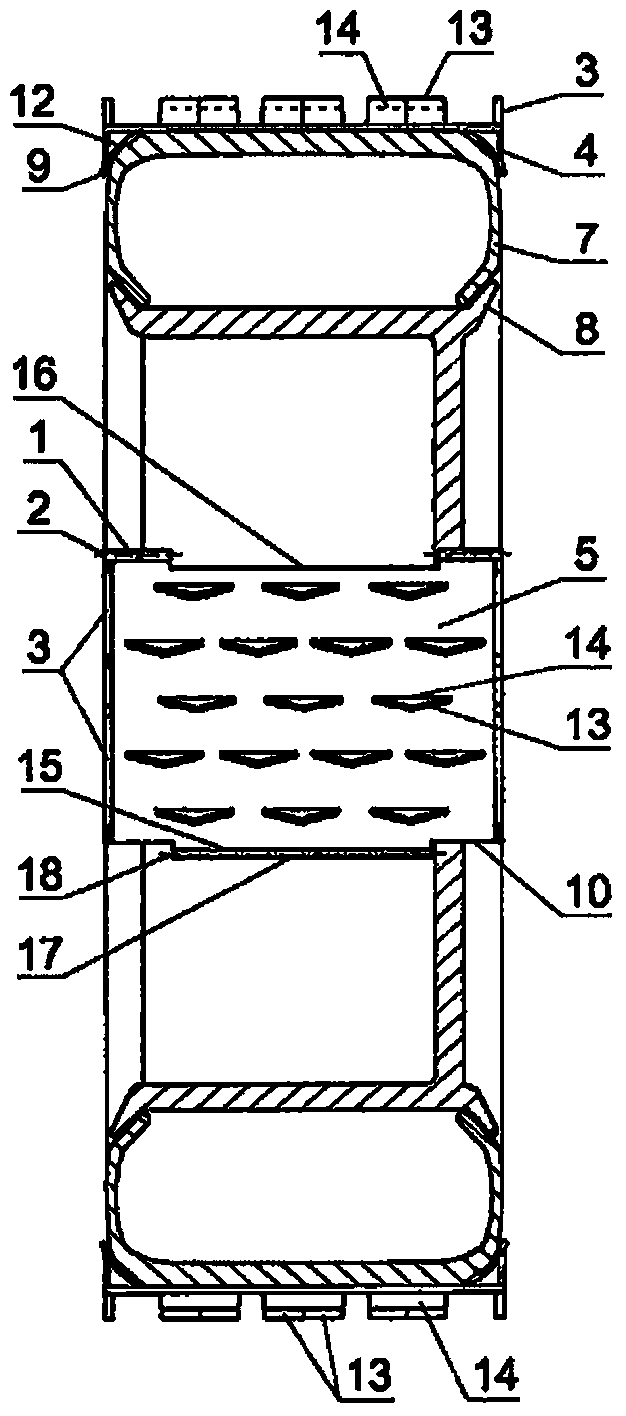

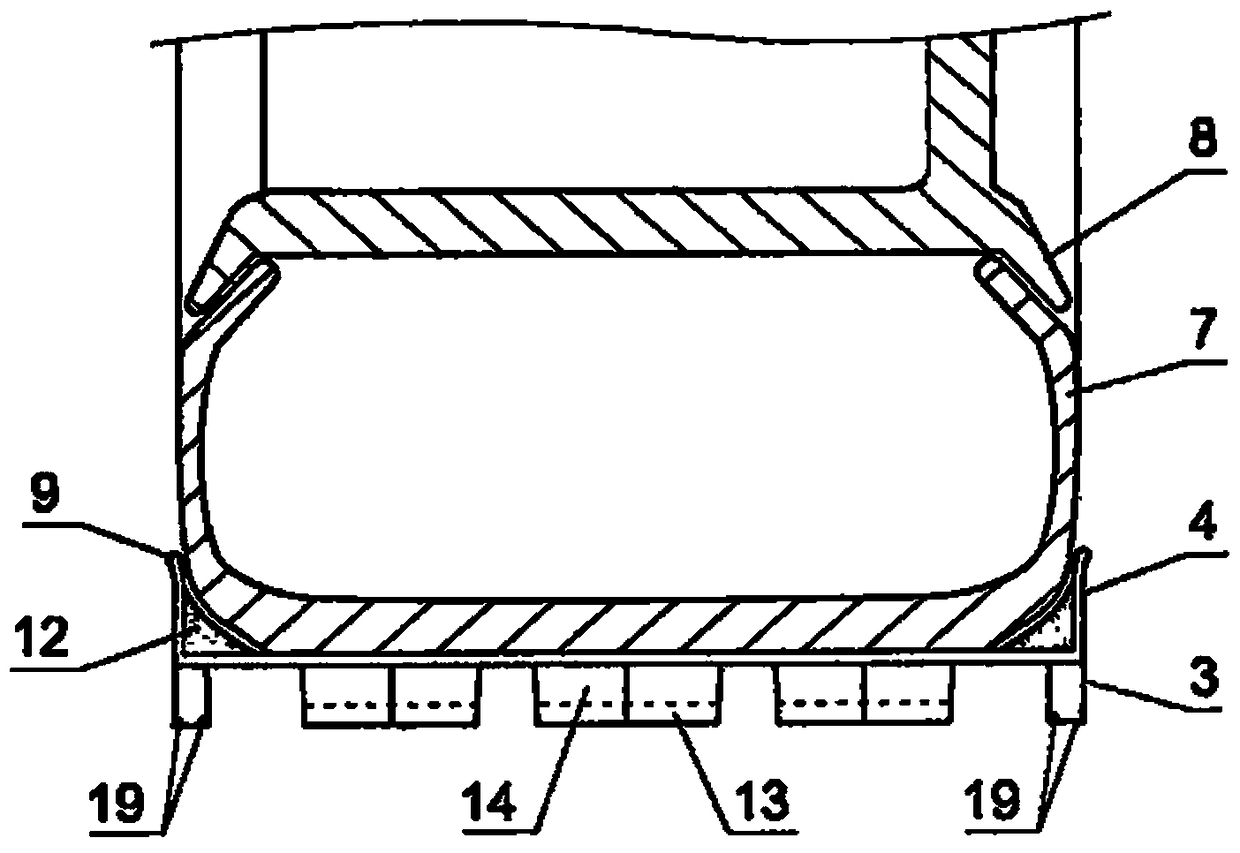

[0025] see Figure 1 to Figure 3 , the present embodiment provides an automobile anti-slip hinge, which includes a first sleeve (1), a first shaft hole (2), an anti-slip sheet (3), a positioning side plate (4), a hinge bottom plate (5 ), rounded corners of anti-slip sheet (6), curling edge (9), floor shoulder (10), rounded corner of positioning side plate (11), buffer pad (12), anti-skid tooth (13), anti-skid tooth base (14 ), the protruding side (15), the concave side (16), the second sleeve (17) and the second shaft hole (18).

[0026] Wrap a group of anti-skid hinges formed by the hinge base plate (5) on the outside of the automobile tire, the anti-skid teeth (13) on the hinge base plate (5) and the anti-skid tooth base (14) form a power anti-skid mechanism, and a set of anti-skid plates (3) Form the anti-skid mechanism, the first sleeve (1), the first shaft hole (2), the bottom plate shoulder (10), the protruding edge (15), the concave edge (16), the second sleeve ( 17) ...

Embodiment 2

[0035] see Figure 1 to Figure 3 , this embodiment provides an automobile anti-skid hinge, the structure of the automobile anti-skid hinge provided in this embodiment is basically the same as the structure of the automobile anti-skid hinge provided in Embodiment 1, the difference is that this embodiment provides The specific composition of the nylon composite material provided in Example 1 is different from that of the nylon composite material. Specifically, the nylon composite material provided in this example is made of the following components by weight: 100 parts of nylon 8I salt, 5 parts of graphene oxide, 6 parts of sepiolite powder, 4 parts of expanded graphite, silane coupling 3.5 parts of agent KH560, 2 parts of nano-carbon sol with a solid content of 22%, 2 parts of nano-titanium dioxide, 3 parts of wollastonite powder, 0.4 parts of benzoic acid, 0.3 parts of 6-aminocaproic acid, and 45 parts of deionized water. The preparation method of this nylon composite materia...

Embodiment 3

[0040] see Figure 1 to Figure 3 , this embodiment provides an automobile anti-skid hinge, the structure of the automobile anti-skid hinge provided in this embodiment is basically the same as the structure of the automobile anti-skid hinge provided in Embodiment 1, the difference is that this embodiment provides The specific composition of the nylon composite material provided in Example 1 is different from that of the nylon composite material. Specifically, the nylon composite material provided in this example is made of the following components by weight: 100 parts of nylon 10T salt, 7 parts of graphene oxide, 7 parts of sepiolite powder, 6 parts of expanded graphite, silane coupling 4 parts of agent KH560, 3 parts of nano-carbon sol with a solid content of 23%, 3 parts of nano-titanium dioxide, 4 parts of wollastonite powder, 0.8 part of benzoic acid, 0.4 part of 6-aminocaproic acid, and 55 parts of deionized water. The preparation method of material comprises the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com