Medical titanium alloy bone implant and preparation method thereof

A technology of bone implants and titanium alloys, which is applied in the field of medical titanium alloy bone implants and its preparation, can solve the problems of high elastic modulus of titanium alloys, achieve good mechanical properties, wear resistance, and good biocompatibility , the effect of low corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

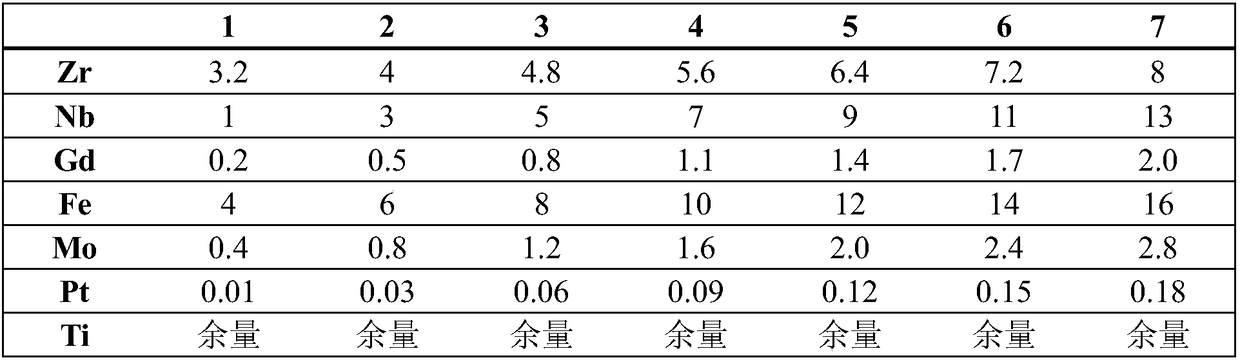

[0020] According to the alloy composition shown in Table 1, the material is selected, and the specific composition is shown in the brackets in Table 1.

[0021] Table 1 Titanium alloy test alloy design composition table (wt%)

[0022]

[0023] The specific preparation process of medical titanium alloy materials is as follows:

[0024] (1) Prepare ingredients: according to the formula amount in Table 1, after mixing each metal powder, mix it in a ball mill for 10h at a rotating speed of 400;

[0025] (2) Raw material melting and casting: The mixed raw materials are smelted in a high-vacuum arc heating furnace, which is first raised to 950°C at a heating rate of 70°C / min, kept for 1.2 hours, and then increased by 1500 at a heating rate of 20°C / min. ℃, fully stirred, then kept for 7 hours, finally poured into an ingot and cooled naturally.

[0026] (3) Homogenization treatment: The obtained ingot is subjected to solution treatment at 800°C, holding time for 10h, and then nat...

Embodiment 2

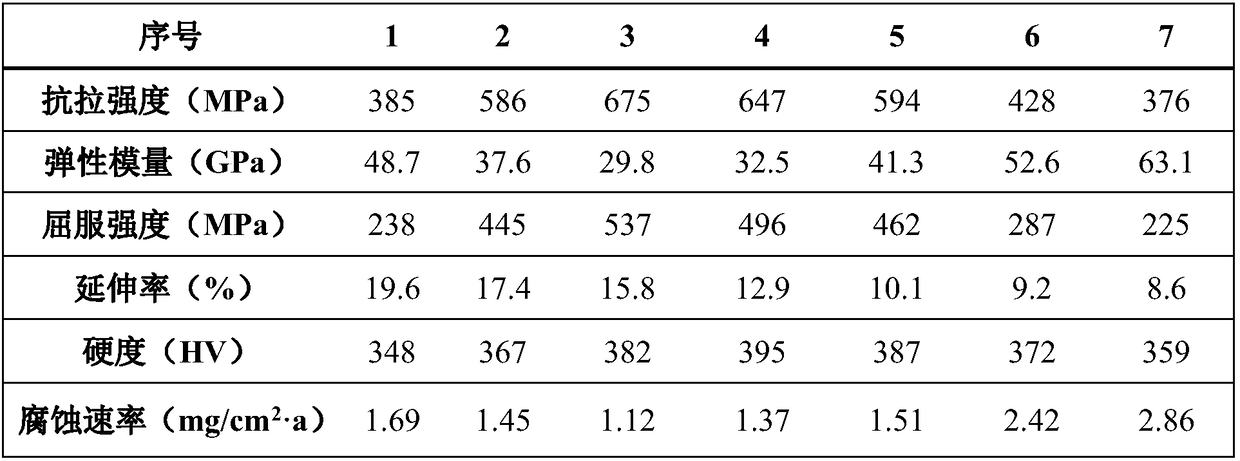

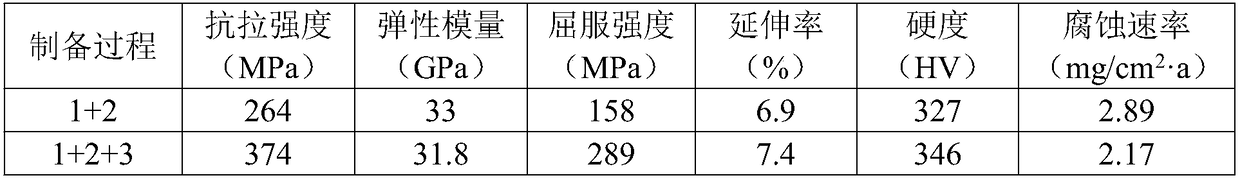

[0034] Example 1 investigated the changes in material properties under the same preparation parameters, when the component contents were different, the present invention not only changed the material components, but also the preparation process was different from the prior art. At the same time, the properties of the obtained material were changed. Specifically, the preparation parameters of No. 3 in Example 1 were unchanged, and the steps 1, 2, 3, 4, 5, and 6 in the preparation process of Example 1 were changed, as shown in Table 3. The properties of the tested materials are shown in Table 3.

[0035] Table 3 Titanium alloy material properties under different preparation steps

[0036]

[0037]

[0038] It can be seen from the performance comparison of No. 3 in Table 3 and Table 2 that to obtain a human implant material with excellent performance based on the material composition of the present invention, the preparation steps of Example 1 of the present invention are i...

Embodiment 3

[0040] Also with the formula of 3 in Example 1 Table 1 as a comparison, the preparation steps are unchanged, and the parameters in each step are changed, as shown below:

[0041] (1) Change the parameters and process in step (2) of Example 1, respectively 1. Without preheating, directly increase the temperature to 1500°C at a heating rate of 20°C / min; 2. After preheating, increase the temperature to 20°C / min The heating rate was increased to 1350 °C; 3. After preheating, the heating rate was increased to 1700 °C at a heating rate of 20 °C / min. The remaining steps are consistent with those disclosed in Example 1, and the mechanical properties of the final material are tested, and the results are as follows:

[0042] The material obtained under the condition of 1 has a tensile strength of 598MPa, an elastic modulus of 37.8GPa, a yield strength of 476MPa, an elongation of 12.5%, a hardness of 357HV, and a corrosion rate of 1.86mg / cm 2 a;

[0043] The tensile strength of the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com