Calcium carbonate crystal whisker reinforced high performance brake disc

A calcium carbonate whisker, high-performance technology, applied in the direction of friction linings, other chemical processes, chemical instruments and methods, etc., can solve the problems of difficult popularization and matching of products, high one-time investment, and large wear and tear of the pair, and achieve cycle The effect of high reuse rate, abundant raw material source, and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

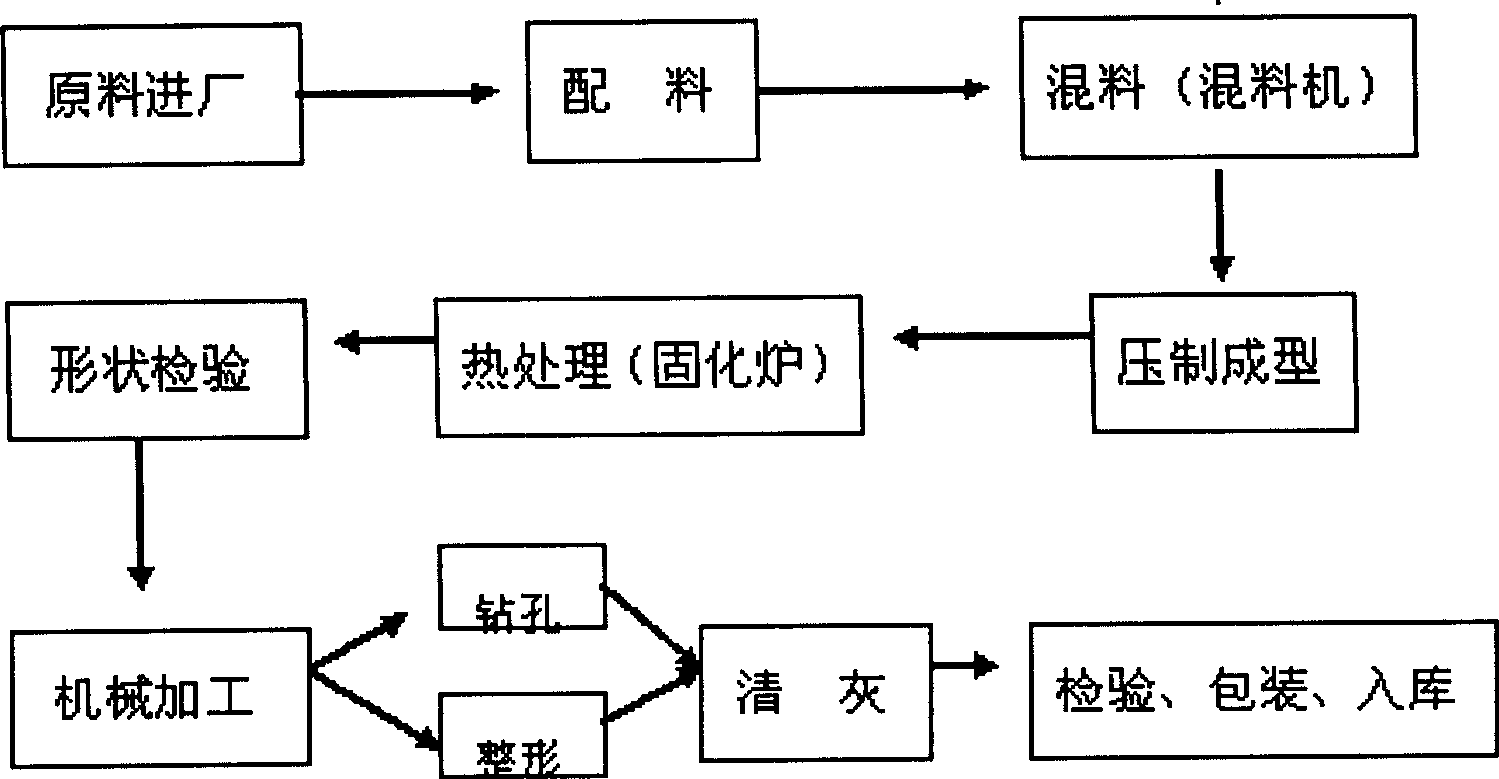

[0009] Example 1: By weight, 10 parts of calcium carbonate whiskers, 15 parts of binder, 30 parts of mineral fiber, 25 parts of graphite, 5 parts of high-temperature binder, 3 parts of aramid fiber, and 10 parts of friction-increasing material , 2 parts of mineral filler. Among them, the calcium carbonate whiskers are selected from aragonite calcium carbonate, whose shape is needle-like single crystal, Mohs hardness is 3, the length is 20-30um, 30-40um, 50-80um and the aspect ratio is 20-30; It is thermoplastic phenolic resin; graphite is flake graphite; mineral fiber is silicate natural inorganic mineral fiber; high-temperature binder is sulfide high-temperature binder such as molybdenum disulfide and antimony sulfide; Oxides; mineral fillers are one or more of light calcium, heavy calcium, barium sulfate, and barium carbonate. according to figure 1 The process implements calcium carbonate whiskers to reinforce high-performance brake pads.

Embodiment 2

[0010] Embodiment 2: By weight ratio, get 20 parts of calcium carbonate whiskers, 10 parts of binder, 20 parts of mineral fiber, 15 parts of graphite, 2 parts of high-temperature binder, 1 part of aramid fiber reinforcement, and 5 parts of friction-increasing material , 27 parts of mineral fillers. Among them, the calcium carbonate whiskers are selected from aragonite calcium carbonate, whose shape is needle-like single crystal, Mohs hardness is 3, the length is 20-30um, 30-40um, 50-80um and the aspect ratio is 20-30; It is thermoplastic phenolic resin; graphite is flake graphite; mineral fiber is silicate natural inorganic mineral fiber; high-temperature binder is sulfide high-temperature binder such as molybdenum disulfide and antimony sulfide; Oxides; mineral fillers are one or more of light calcium, heavy calcium, barium sulfate, and barium carbonate. according to figure 1 The process implements calcium carbonate whiskers to reinforce high-performance brake pads.

Embodiment 3

[0011] Embodiment 3: By weight ratio, get 15 parts of calcium carbonate whiskers, 12 parts of binder, 25 parts of mineral fiber, 20 parts of graphite, 3 parts of high-temperature binder, 2 parts of aramid reinforcing fiber, and 8 parts of friction-increasing material , 15 parts of mineral fillers. Among them, the calcium carbonate whiskers are selected from aragonite calcium carbonate, whose shape is needle-like single crystal, Mohs hardness is 3, the length is 20-30um, 30-40um, 50-80um and the aspect ratio is 20-30; The agent is thermoplastic phenolic resin; the graphite is flake graphite; the mineral fiber is silicate-type natural inorganic mineral fiber; the high-temperature binder is a sulfide high-temperature binder such as molybdenum disulfide and antimony sulfide; Metal oxides; mineral fillers are one or more of light calcium, heavy calcium, barium sulfate, and barium carbonate. according to figure 1 The process implements calcium carbonate whiskers to reinforce high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com