Photovoltaic member heat-transfer coefficient testing device and method thereof

A heat transfer coefficient and photovoltaic component technology, applied in the field of photovoltaic component heat transfer coefficient test equipment, can solve the problems that there is no photovoltaic component laboratory test device and test method, and the photovoltaic component heat transfer coefficient test system has not yet been formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

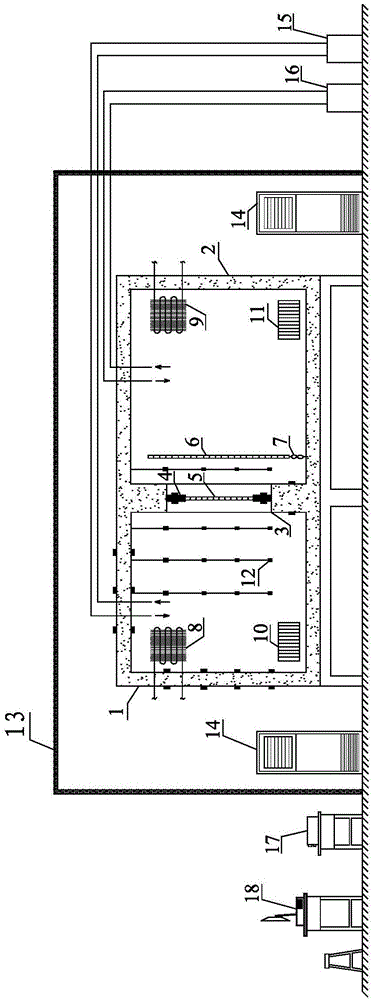

[0046] see figure 1 and figure 2 As shown, the embodiments of the present invention will be described in detail.

[0047] like figure 1As shown, a photovoltaic component heat transfer coefficient testing device involved in the present invention, the testing device includes an indoor box 1, an outdoor box 2, a test piece frame 3, a filling plate 4, an electrothermal film member 5, a wind shield 6, Fan 7, first evaporator 8, second evaporator 9, first electric heater 10, second electric heater 11, multiple temperature sensors 12, environmental space box 13, air conditioner 14, first humidity control device 15, The second humidity control device 16, the electrothermal film power supply 17 and the control and data acquisition system 18;

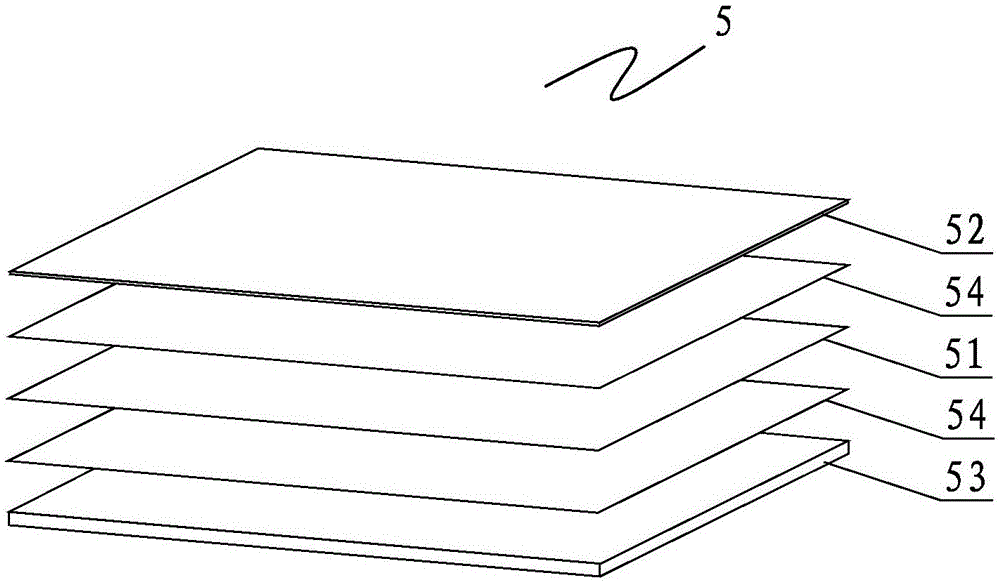

[0048] The indoor box 1 is arranged adjacent to the outdoor box 2 and has an overlapping surface, the test piece frame 3 is arranged on the overlapping surface, the upper and lower sides of the test piece frame 3 are provided with filling pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com