Preparation method and application of intelligent heat storage and temperature regulation nano aerogel fiber

A nano-aerogel, heat storage and temperature adjustment technology, applied in the direction of fiber type, fiber treatment, heat exchange materials, etc., can solve the problems of poor durability, high cost, high preparation conditions, etc., to achieve phase change stability and durability Excellent performance, maintain energy storage capacity, and long-term wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

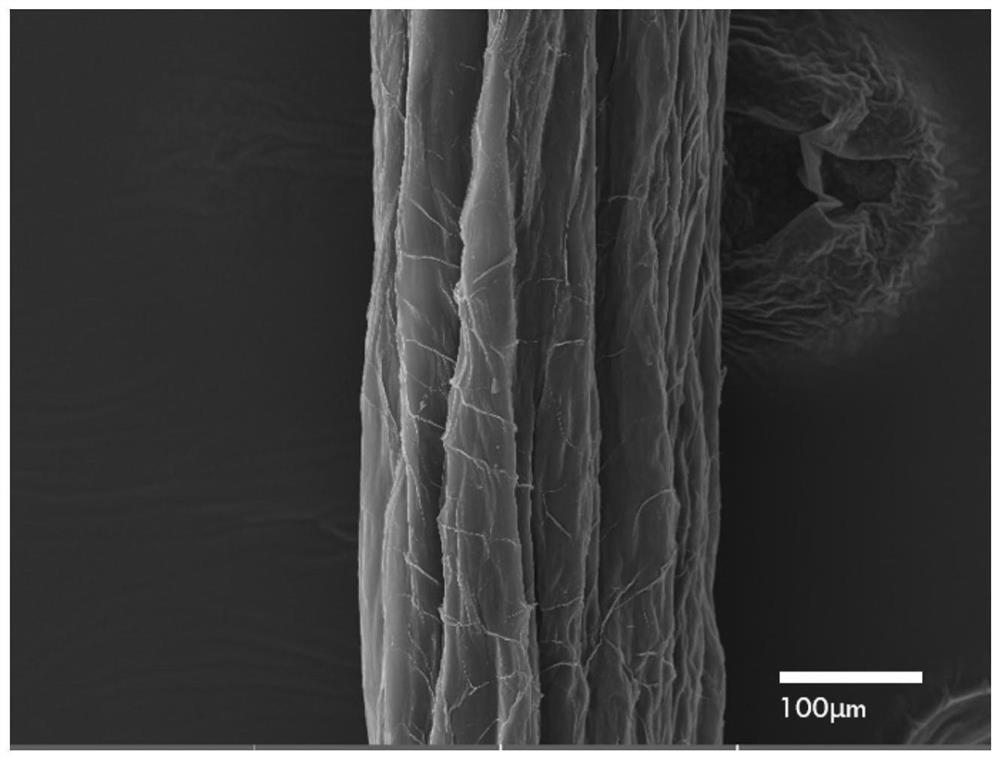

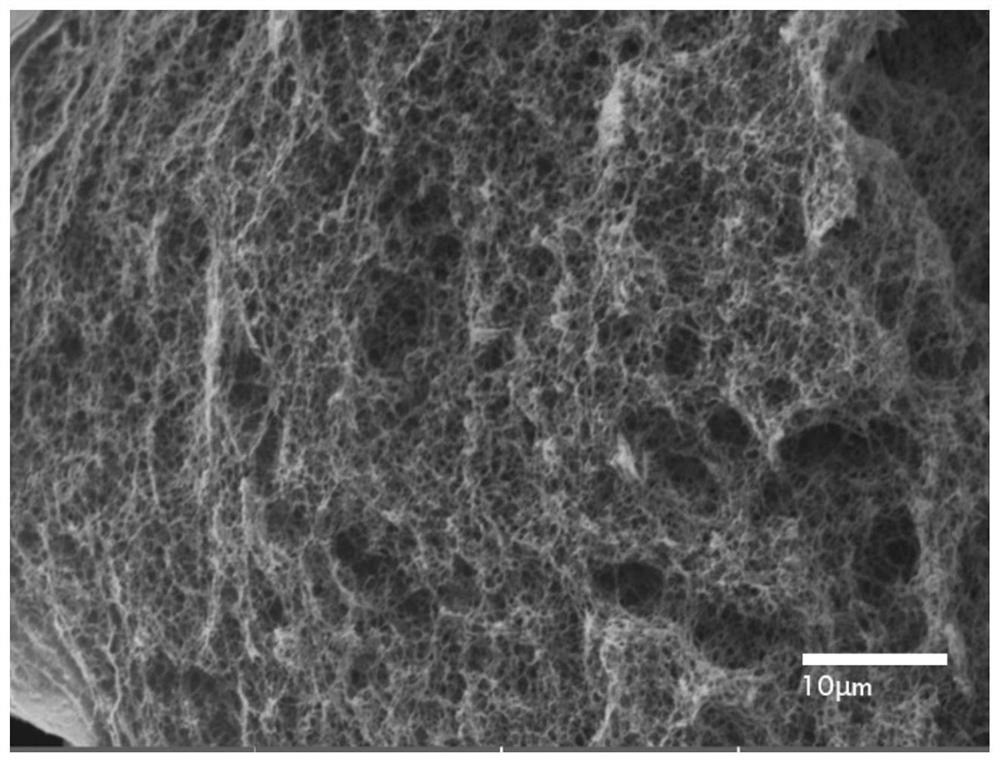

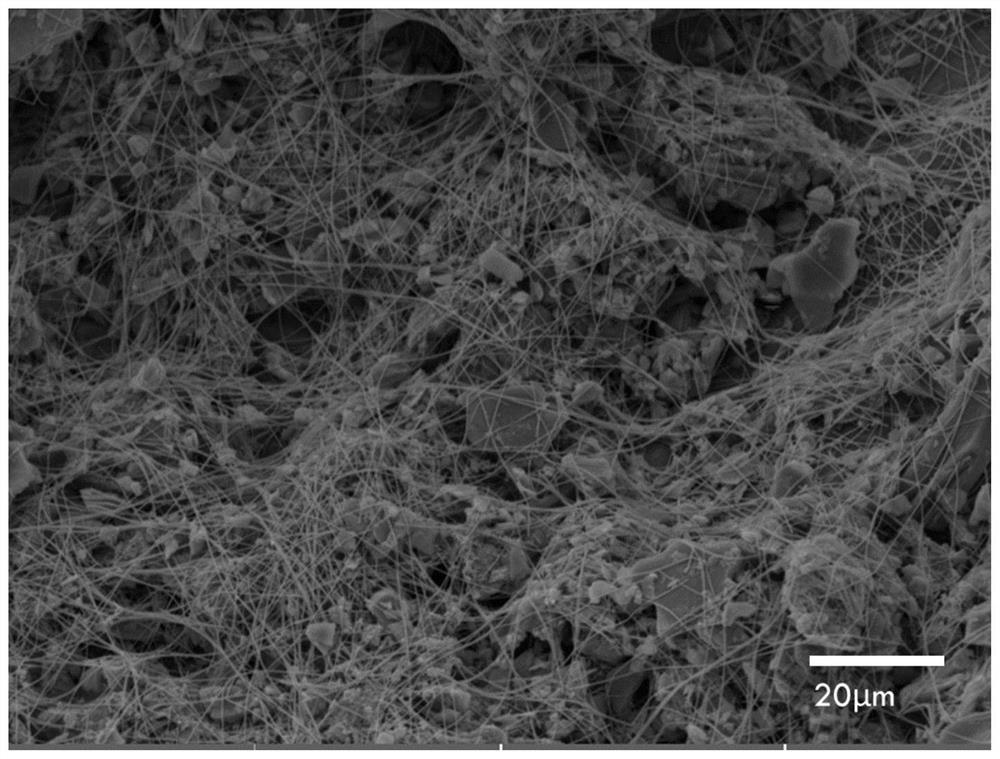

[0038] Such as Figure 1-6 Shown, a kind of preparation method of nanometer airgel fiber of intelligent heat storage temperature regulation, comprises the following steps:

[0039] S1. The fiber is aramid fiber. In an alkaline environment, the nitrogen atoms on the amide group of the aramid fiber are deprotonated to achieve macroscopic fiber dispersion, forming nano-monomers and stably existing aramid nano-monomer dispersion liquid, that is, aramid nanofiber dispersion; in order to obtain 1wt% aramid nanofiber dispersion, take 0.45g aramid fiber and the same amount of tert-butanol and methanol into a flask filled with 40mlDMSO, and mechanically stir for 3h to obtain 1wt% dispersion;

[0040] S2. Then the nano-monomer dispersion liquid obtained in step S1 is 0.03mm / s at an extrusion speed, and the coagulation bath liquid adopts 10wt% dimethyl sulfoxide aqueous solution, and wet spinning becomes aramid fiber nanofiber, nanofiber The extruded diameter is controlled to be 1mm to...

Embodiment 2

[0050] S1. The fiber is aramid fiber. In an alkaline environment, the nitrogen atoms on the amide group of the aramid fiber are deprotonated to achieve macroscopic fiber dispersion, forming nano-monomers and stably existing aramid nano-monomer dispersion liquid, that is, aramid nanofiber dispersion; in order to obtain 1wt% aramid nanofiber dispersion, take 0.45g of aramid fiber and an equivalent amount of tert-butanol and methanol into a flask filled with 40ml of DMSO, and mechanically stir for 4h to obtain 1wt% dispersion;

[0051] S2. Then the nano-monomer dispersion liquid obtained in step S1 is 0.03mm / s at an extrusion speed, and the coagulation bath liquid adopts 10wt% dimethyl sulfoxide aqueous solution, and wet spinning becomes aramid fiber nanofiber, nanofiber The extruded diameter is controlled to be 1mm to obtain primary airgel fibers;

[0052] S3. The primary airgel fiber obtained in step S2 is freeze-dried in a freeze dryer to remove water in the fiber, and the fr...

Embodiment 3

[0056] S1. The fiber is aramid fiber. In an alkaline environment, the nitrogen atoms on the amide group of the aramid fiber are deprotonated to achieve macroscopic fiber dispersion, forming nano-monomers and stably existing aramid nano-monomer dispersion liquid, that is, aramid nanofiber dispersion; in order to obtain 1wt% aramid nanofiber dispersion, take 0.45g aramid fiber and the same amount of tert-butanol and methanol into a flask filled with 40mlDMSO, and mechanically stir for 5h to obtain 1wt% dispersion;

[0057] S2. Then the nano-monomer dispersion liquid obtained in step S1 is 0.03mm / s at an extrusion speed, and the coagulation bath liquid adopts 10wt% dimethyl sulfoxide aqueous solution, and wet spinning becomes aramid fiber nanofiber, nanofiber The extruded diameter is controlled to be 1mm to obtain primary airgel fibers;

[0058] S3. The primary airgel fiber obtained in step S2 is freeze-dried for 20 hours in a freeze dryer to obtain a nano-airgel fiber substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com