Preparation method of chopped carbon fiber composite material

A technology of chopped carbon fiber and carbon composite materials, which is applied in the field of preparation of carbon fiber composite materials, can solve the problems of serious waste liquid environmental pollution, large product performance differences, complex operation process, etc., and achieve simple process, short preparation cycle, and increase ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

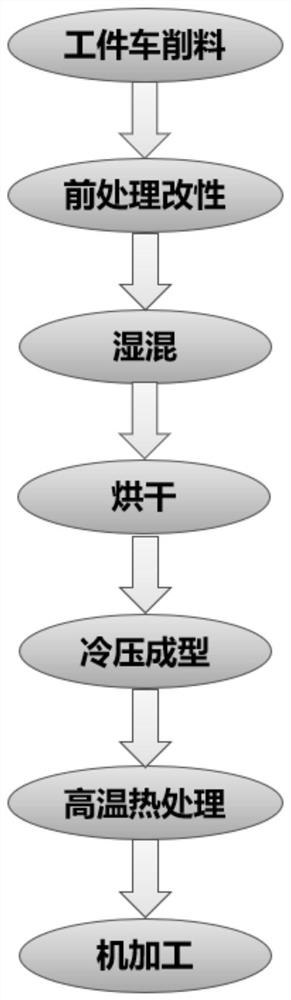

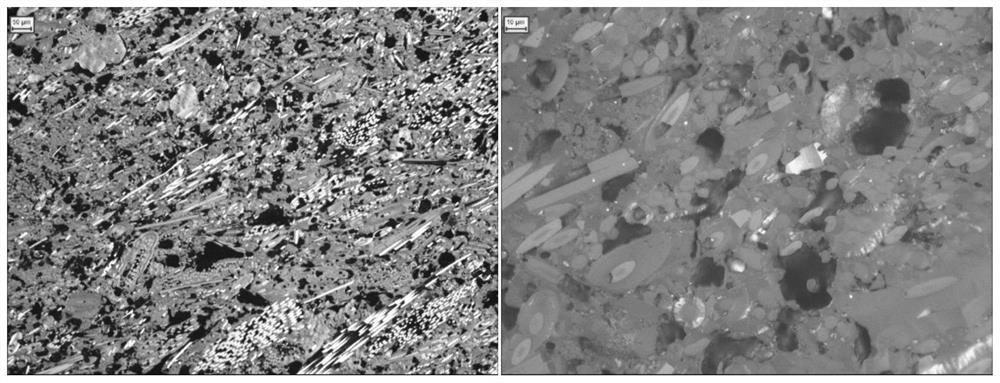

[0053] A certain amount of turning material of carbon / carbon composite material is taken, and a carbon fiber composite material is obtained through the following preparation process.

[0054] Step 1) Pre-processing of solid waste materials:

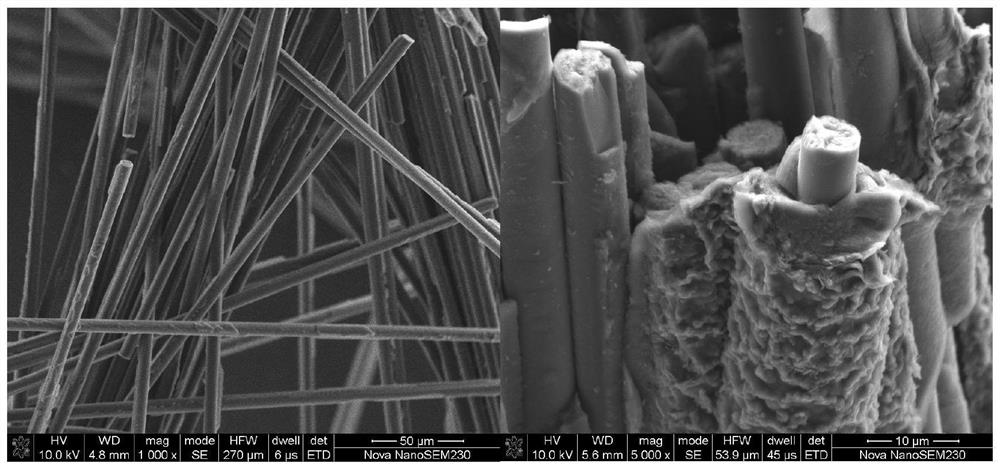

[0055] Crushing and screening→acid-base washing→drying→oxidation treatment→surface mechanical modification

[0056] Turning solid waste materials are firstly crushed and screened with a screen size of 50 mesh, and then the impurities generated during the collection process are removed by acid-base washing and surface activation is carried out. After washing, drying and surface oxidation treatment are carried out, and finally through mechanical modification. Do final treatment to obtain resin modified coated carbon powder and chopped carbon fiber powder;

[0057] Step 2) Wet mixing: put the recycled chopped carbon fiber, commercial chopped carbon fiber, thermosetting resin and dissolving agent into a mixer according to a certain ratio and...

Embodiment 2

[0073] According to the preparation method of a kind of chopped carbon fiber composite material in embodiment 1

[0074] In the first step, the pretreatment process of solid waste treatment is the same as that in Example 1.

[0075] In the second step, the proportion of recycled carbon fiber in the mixture is 60%, commercial chopped carbon fiber is 10%, modified suspension resin is 30%, and the mass ratio of resin to solvent is 1:2.5. The commercial carbon fiber used The average length is 12mm, the diameter is 0.5mm, the thermosetting resin used is phenolic resin, and the solvent used is methanol.

[0076] In the third step, the drying temperature is 140° C., and the holding time is 3 hours.

[0077] In the step 4, the specific process of cold pressing is as follows: when the pressing pressure is 8 MPa, keep the pressure for 2 minutes; when the pressing pressure is 15 MPa, keep the pressure for 2 minutes; when the pressing pressure is 200 MPa, keep the pressure for 1 minute. ...

Embodiment 3

[0083] According to the preparation method of a kind of chopped carbon fiber composite material in embodiment 1

[0084] In said step one, the pretreatment process of solid waste treatment is the same as that of Example 1;

[0085] In the second step, the proportion of pre-treated recycled carbon fiber in the mixture is 60%, commercial chopped carbon fiber is 5%, modified suspension resin is 35%, and the mass ratio of resin to solvent is 1:3. The average length of the commercial carbon fibers used is 12 mm, and the diameter is 0.5 mm. The thermosetting resin used is phenolic resin, and the solvent used is methanol.

[0086] In the third step, the drying temperature is 140° C., and the holding time is 3 hours.

[0087] In the step 4, the specific process of cold pressing is as follows: when the pressing pressure is 10 MPa, keep the pressure for 1 minute; when the pressing pressure is 20 MPa, keep the pressure for 1 minute; when the pressing pressure is 150 MPa, keep the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com