Powder metallurgy preparation method of high volume fraction SiCp/Al alloy composite

A high volume fraction, composite material technology, applied in the field of the preparation of alloy composite materials, can solve the problems of difficult to prepare large size, shape devices or products, large interface reactivity, increase the interface thermal resistance of composite materials, etc., to achieve excellent mechanical and Thermophysical properties, uniform distribution of SiCp, effect of uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: 50vol% SiCp / 6061Al composite material, sintered under normal pressure at 680°C

[0023] (1) Elutriation: ultrasonically treat the commercially available SiC powder in deionized water for 10 minutes, then let it stand for 10 minutes, pour out the deionized water together with the fine SiC particles suspended in it, and repeat the elutriation for 3-5 times. Until the deionized water is completely clarified; the SiC powder after elutriation is kept and dried at 150°C for 12 hours for later use, and the average particle diameter of the SiCp powder after elutriation (d 50 ) is 20 μm;

[0024] (2) Ingredients: mix the SiCp powder after washing with the commercially available average particle size (d 50 ) is 25 μm Al alloy powder according to the volume ratio of 1:1;

[0025] (3) Mixing: The mixing of SiCp powder and Al alloy powder is carried out on a double-shaft drum mixer, and ZrO with a diameter of 5mm is added. 2 The ball is used as the mixing medium, the b...

Embodiment 2

[0030] Example 2: 50vol% SiCp / 6061Al composite material, sintered under normal pressure at 660°C

[0031] The preparation process of this embodiment is the same as that of Embodiment 1, except that the sintering temperature in step (5) is 660° C., and other processes and parameters remain unchanged.

Embodiment 3

[0032] Example 3: 50vol% SiCp / 6061Al composite material, sintered at 700°C under normal pressure

[0033] The preparation process of this embodiment is the same as that of Embodiment 1, except that the sintering temperature in step (5) is 700° C., and other processes and parameters remain unchanged.

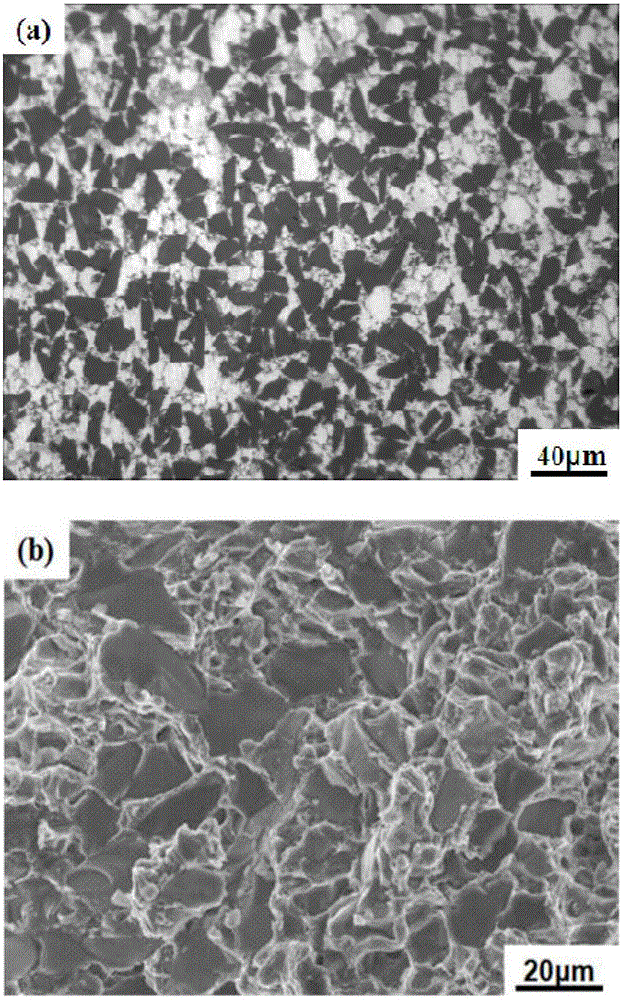

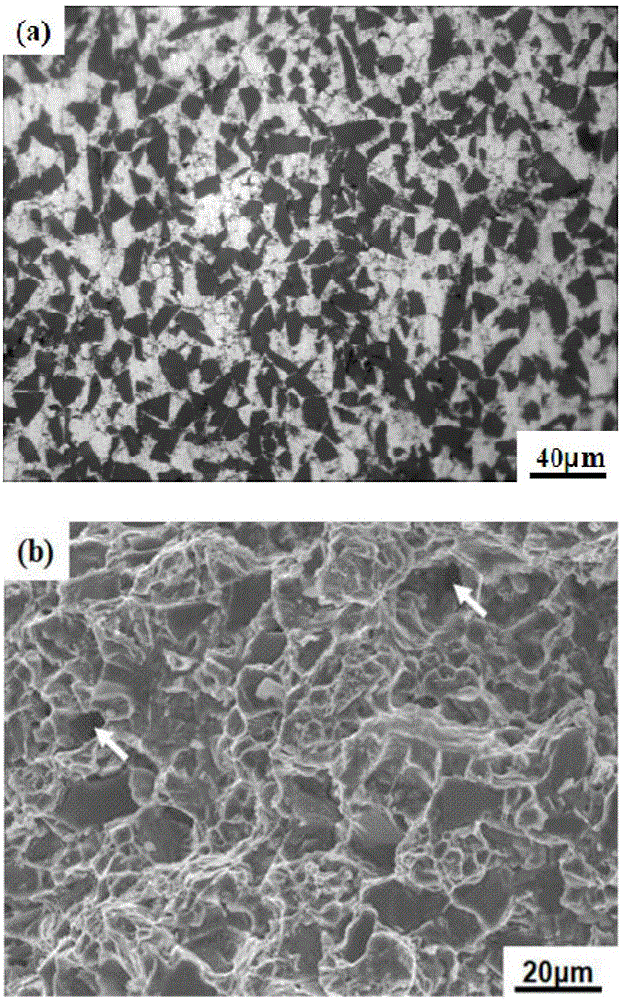

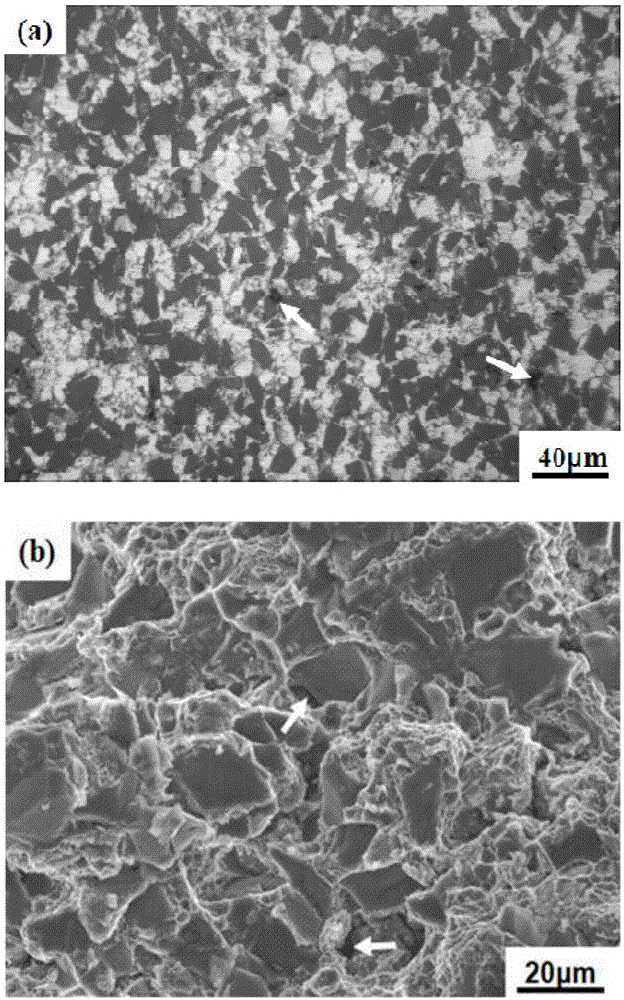

[0034] Such as Figure 1-3As shown, the SiCp in the atmospheric pressure sintered 50vol% SiCp / Al alloy composite material is evenly distributed in the Al alloy matrix without agglomeration phenomenon, and the composite material has low porosity and high density. SiCp in the 50vol% SiCp / Al alloy composite material sintered at 680 ° C in Example 1 is most tightly combined with the Al alloy matrix, without pores ( figure 1 ). However, in 50vol% SiCp / Al alloy composites sintered at lower or higher temperatures than 680°C (Example 2, 3), there are fine pores at the Al alloy matrix or its SiCp interface, and the density decreases, and sintering at 700°C The 50vol% SiCp / Al alloy comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com