Preparation method for nanocrystalline alumina ceramic

A technology of nano-crystalline alumina and micro-alumina is applied in the field of low-temperature pre-sintering and high-temperature sintering to prepare nano-crystalline alumina ceramics, which can solve the problems of increasing factory production costs, difficulty in preparing nano-powders, high susceptibility to pollution, etc. The effect of reducing the cost of raw materials, optimizing the microstructure of alumina ceramics, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Preparation of nanocrystalline alumina ceramics by low-temperature pre-firing and high-temperature sintering The specific preparation steps are as follows:

[0016] 1. Pre-pressing of ceramic powder:

[0017] Pour 2.5g of powder with a particle size of 3μm into a Φ20mm graphite mold, and mold it under a pressure of 5MPa for 60s;

[0018] 2. Sintering of ceramic powder:

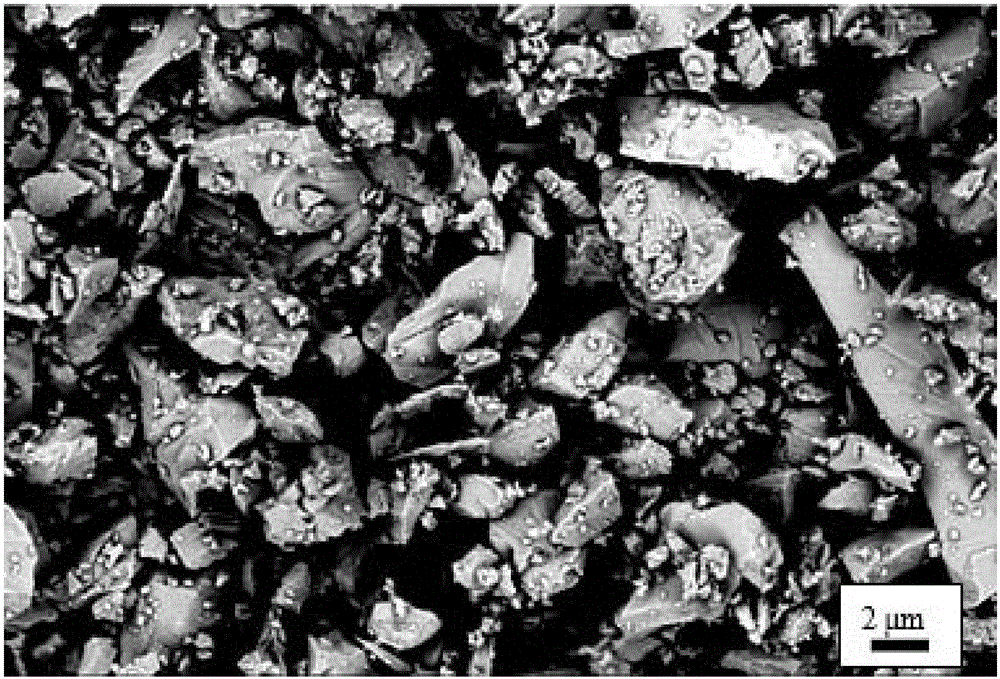

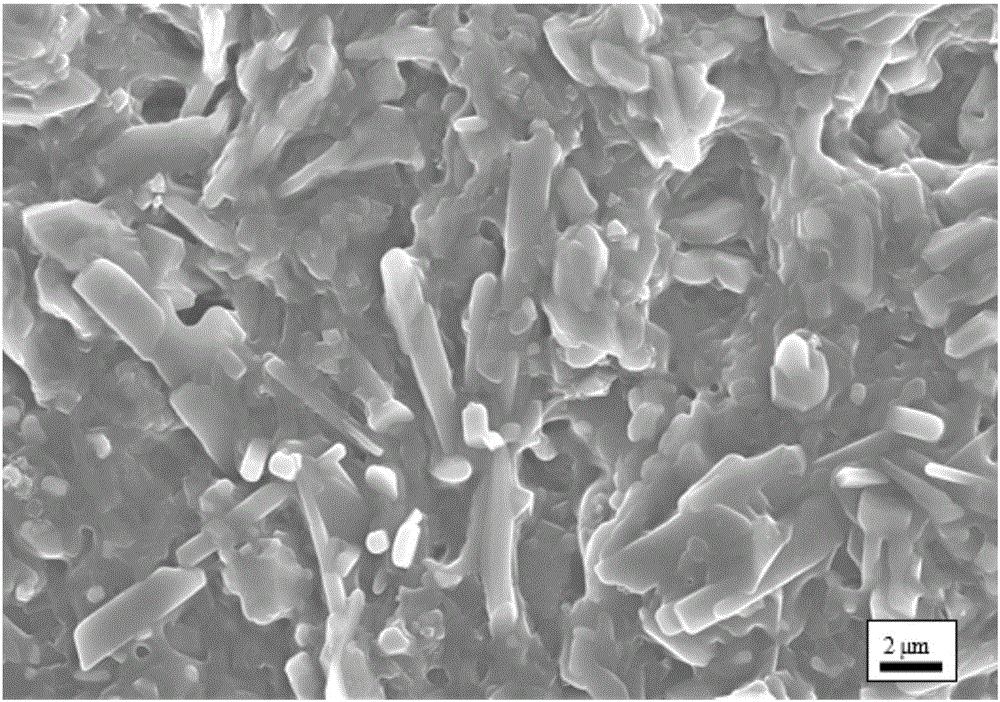

[0019] Put the molded sample into a spark plasma sintering furnace, heat it to 800°C at a heating rate of 150°C / min, and keep it at this temperature for 10 minutes; 1300°C, and kept at this temperature for 2 minutes; then cooled naturally to room temperature. During the sintering process, the pressure is pre-loaded to 5kN, and then slowly increased to 50MPa during low-temperature pre-firing. The heating method is pulse current heating, the cycle pulse process is set to a single pulse time of 3.3ms, and the pause is 6.6ms after 12 consecutive pulses. Alumina ceramics with uniform nanocryst...

Embodiment 2

[0020] Embodiment 2: The preparation steps of nanocrystalline alumina ceramics are as follows:

[0021] 1. Pre-pressing of ceramic powder:

[0022] Pour 2.5g of powder with a particle size of 3μm into a Φ20mm graphite mold, and mold it under a pressure of 5MPa for 60s;

[0023] 2. Sintering of ceramic powder:

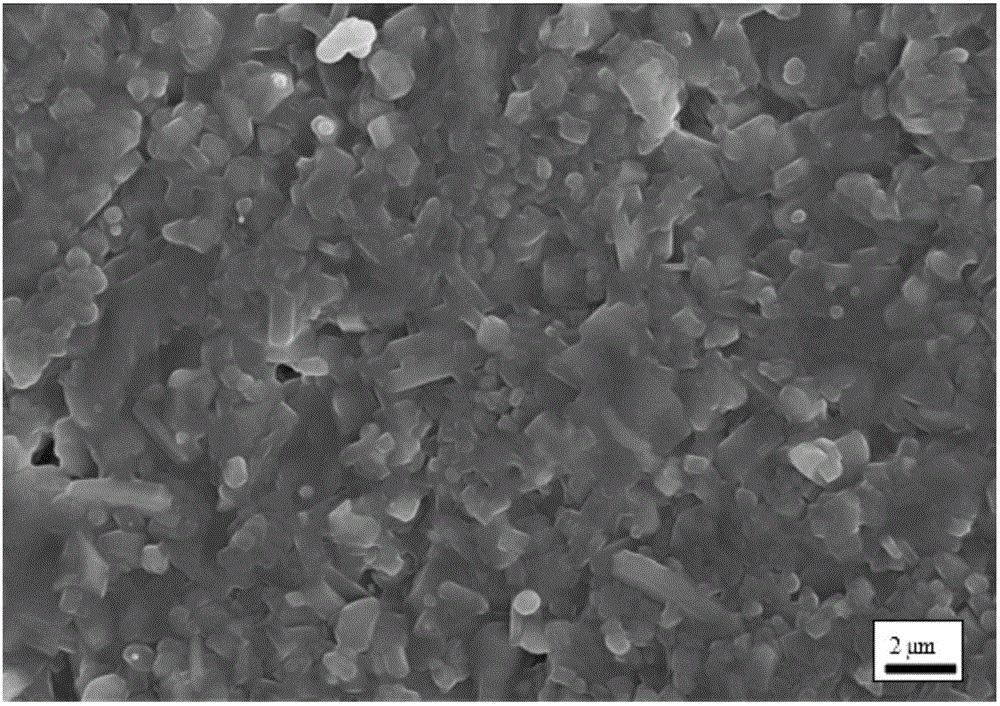

[0024] Put the molded sample into a spark plasma sintering furnace, heat it to 950°C at a heating rate of 150°C / min, and keep it at this temperature for 5 minutes; 1300°C, and kept at this temperature for 2 minutes; then cooled naturally to room temperature. During the sintering process, the pressure is pre-loaded to 5kN, and then slowly increased to 50MPa during low-temperature pre-firing. The heating method is pulse current heating, the cycle pulse process is set to a single pulse time of 3.3ms, and the pause is 6.6ms after 12 consecutive pulses. Alumina ceramics with uniform nanocrystals are finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com