Preparation method of large-size and fine-grain molybdenum tantalum alloy sputtering target material

A sputtering target, large-scale technology, applied in the target field, can solve the problems of inability to use rolling production, high alloy temperature, target import, etc., to overcome poor dimensional accuracy, uniform grain distribution, and difficult to bubble. and the effect of segregation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The method for preparing a large-size, fine-grained molybdenum-tantalum alloy sputtering target comprises the following steps: step 1, pretreating molybdenum powder and tantalum powder and then sieving respectively, the Fischer particle size of tantalum powder and molybdenum powder after sieving The ratio is 1.6:1, and the sieved molybdenum powder and tantalum powder are ball milled and mixed according to the mass ratio of 90~94:6~10 for more than 16 hours, and the molybdenum-tantalum mixed powder is prepared for use;

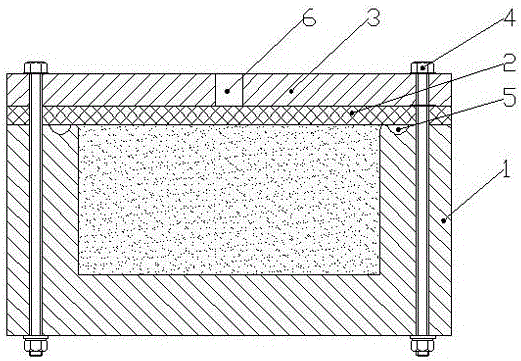

[0026] Step 2. According to the target size of the required compact, weigh the mass or volume of the molybdenum-tantalum mixed powder required to form a compact, and make a cold isostatic pressing mold with the same volume as the molding cavity and the molybdenum-tantalum mixed powder , using a powder feeder to make the molybdenum-tantalum mixed powder freely fall into the forming cavity of the cold isostatic pressing mold. Blank, spare;

[0027] Step 3...

Embodiment 1

[0034] The preparation method of large-size, fine-grained molybdenum-tantalum alloy sputtering target material comprises the following steps: step 1, pretreating molybdenum powder and tantalum powder and then sieving respectively, the Fischer particle size of tantalum powder after sieving is 9.6 microns , the Fischer particle size of the molybdenum powder is 6 microns, and the molybdenum powder and tantalum powder after sieving are ball-milled and mixed according to a mass ratio of 94:6 for 16 hours to obtain a molybdenum-tantalum mixed powder for subsequent use; wherein, the pretreatment method is: Molybdenum powder and tantalum powder were annealed under vacuum condition for 2h, and the annealing temperature was 1300°C.

[0035] Step 2. According to the target size of the required compact, weigh the mass or volume of the molybdenum-tantalum mixed powder required to form a compact, and make a cold isostatic pressing mold with the same volume as the molding cavity and the molyb...

Embodiment 2

[0042] The preparation method of large-size, fine-grained molybdenum-tantalum alloy sputtering target material comprises the following steps: step 1, pretreating molybdenum powder and tantalum powder and then sieving respectively, the Fischer particle size of tantalum powder after sieving is 16 microns , the Fischer particle size of the molybdenum powder is 10 microns, and the molybdenum powder and tantalum powder after sieving are ball-milled and mixed according to the mass ratio of 90:10 for 20 hours, and the molybdenum-tantalum mixed powder is prepared for subsequent use; the pretreatment method is: Molybdenum powder and tantalum powder were annealed under vacuum condition for 2h, and the annealing temperature was 1300°C.

[0043] Step 2. According to the target size of the required compact, weigh the mass or volume of the molybdenum-tantalum mixed powder required to form a compact, and make a cold isostatic pressing mold with the same volume as the molding cavity and the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com