Production method of high-density long-life tungsten-molybdenum alloy crucible

A technology of tungsten-molybdenum alloy and production method, applied in metal processing equipment, metal material coating technology, gaseous chemical plating and other directions, can solve the problems of difficulty in producing high density and long life, and achieve dense organization, uniform grains, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A production method of a high-density and long-life tungsten-molybdenum alloy crucible comprises the following steps: step 1, pretreating tungsten powder and molybdenum powder and then screening respectively, the pretreatment process is: tungsten powder and molybdenum powder are placed under vacuum conditions The annealing treatment was carried out at 1300°C for 2 hours; the particle size of the tungsten powder after sieving was 20 microns, and the particle size of the molybdenum powder was 10 microns. Carry out ball milling 5h, make tungsten-molybdenum mixed powder, set aside;

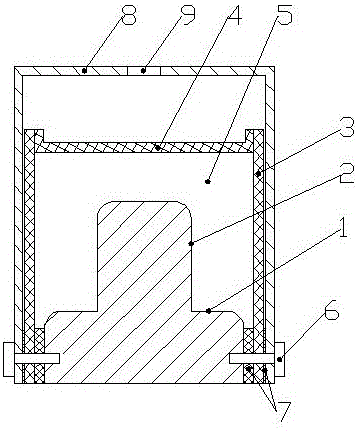

[0032] Step 2. According to the target size of the required crucible, weigh the mass or volume of the tungsten-molybdenum mixed powder required to form a crucible, and make a cold isostatic pressing mold with the same volume as the molding cavity and the tungsten-molybdenum mixed powder, and cold The structure of the isostatic pressing die is as described above, specifically as figure 1 As show...

Embodiment 2

[0037] A molding method of tungsten and molybdenum powder metallurgy products, comprising the following steps: step 1, pretreating tungsten powder and molybdenum powder and then screening respectively, the pretreatment process is: annealing the tungsten powder and molybdenum powder under vacuum conditions 2h, the annealing temperature is 1300°C; the particle size of the sieved tungsten powder is 0.6 microns, and the particle size of the molybdenum powder is 0.05 microns, and the sieved tungsten powder and molybdenum powder are mixed according to the mass ratio of 9:1 and ball milled for 1 hour. Then mix at room temperature for 20 hours to obtain tungsten-molybdenum mixed powder, which is set aside;

[0038] Step 2. According to the target size of the required crucible, weigh the mass or volume of the tungsten-molybdenum mixed powder required to form a crucible, and make a cold isostatic pressing mold with the same volume as the molding cavity and the tungsten-molybdenum mixed p...

Embodiment 3

[0043] A method for forming a tungsten-molybdenum powder metallurgy product, comprising the following steps: step 1, sieving the tungsten powder and the molybdenum powder after pretreatment, the particle size of the tungsten powder after screening is 0.25 microns, and the particle size of the molybdenum powder is 0.1 microns , mix the sieved tungsten powder and molybdenum powder according to the mass ratio of 4:6, then ball mill for 3 hours, and then mix at room temperature for 20 hours to obtain tungsten-molybdenum mixed powder for later use; wherein, the pretreatment process is: the tungsten The powder and molybdenum powder were annealed for 2 hours under vacuum conditions, and the annealing temperature was 1300°C;

[0044] Step 2. According to the target size of the required crucible, weigh the mass or volume of the tungsten-molybdenum mixed powder required to form a crucible, and make a cold isostatic pressing mold with the same volume as the molding cavity and the tungsten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com