Anti-impact flexible protective composite material based on shear thickening adhesive and preparation method thereof

A flexible protection and composite material technology, applied in protective equipment, protective clothing, chemical instruments and methods, etc., can solve problems such as insufficient impact resistance, and achieve excellent vibration and impact resistance, the process is simple and easy to operate, and easy to achieve. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

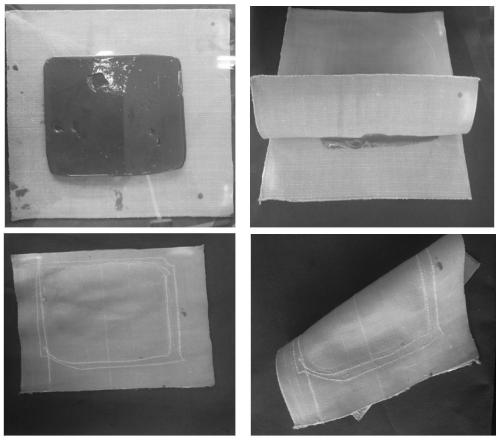

[0027] A kind of impact-resistant flexible protection composite material based on shear thickening glue, its preparation method comprises the steps:

[0028] (1) Preparation of shear thickening glue, which consists of the following components:

[0029] 200g polydimethylsiloxane, 16g boric acid, 11g tetraacicular zinc oxide (the length of the needles is 10-510 μm, the diameter of the roots of the needles is 0.5-5 μm);

[0030] Dehydrate boric acid at 160°C for 2 hours, then add boric acid to polydimethylsiloxane, mix and stir in a kneader under the conditions of pressure 15kPa and temperature 200°C, mix and stir for about 0.5h, then add tetrapod Zinc oxide, the three were stirred together for about 0.5h to obtain a shear thickening glue.

[0031] (2) Mix 150g of shear thickening glue with 150g of isopropanol to obtain a dilution of the shear thickening glue. In order to obtain a flexible protective composite material with better performance, add 10g four-needle zinc oxide and...

Embodiment 2

[0035] A kind of impact-resistant flexible protection composite material based on shear thickening glue, its preparation method comprises the steps:

[0036] (1) Preparation of shear thickening glue, which consists of the following components:

[0037] 200g polydimethylsiloxane, 20g boric acid, 7g tetraacicular zinc oxide (the length of the needles is 10-510 μm, the diameter of the root of the needles is 0.5-5 μm);

[0038] Dehydrate boric acid at 160°C for 2 hours, then add boric acid to polydimethylsiloxane, mix and stir in a kneader under the conditions of a pressure of 15kPa and a temperature of 180°C, mix and stir for about 1 hour, then add tetrapod oxide Zinc, and the three were stirred together for about 1 hour to obtain a shear-thickening gel.

[0039] (2) 150g shear thickening glue is mixed with 300g isopropanol to obtain the dilution of shear thickening glue, place it after the shear thickening glue dissolves to obtain the dilution of shear thickening glue; Step (1...

Embodiment 3

[0043] A kind of impact-resistant flexible protection composite material based on shear thickening glue, its preparation method comprises the steps:

[0044] (1) Preparation of shear thickening glue, which consists of the following components:

[0045] 200g polydimethylsiloxane, 10g boric acid, 5g tetraacicular zinc oxide (needle length is 10-510μm, needle-shaped root diameter 0.5-5μm);

[0046] Dehydrate boric acid at 160°C for 2 hours, then add boric acid to polydimethylsiloxane, mix and stir in a kneader under the conditions of a pressure of 15kPa and a temperature of 160°C, mix and stir for about 1.5 hours, then add tetrapods Zinc oxide, and the three were stirred together for about 1.5 hours to obtain a shear-thickening glue.

[0047] (2) 150g shear thickening glue is mixed with 450g isopropanol to obtain a dilution of the shear thickening glue, and the shear thickening glue is placed after dissolving to obtain a dilution of the shear thickening glue; Step (1) The product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com