Six-freedom degree wearing type auxiliary bone-knitting parallel-connected robot

A wearable, degree-of-freedom technology, used in robotics, medical science, surgery, etc., can solve the problem of inability to take into account plastic reduction and fixation, and achieve the effect of reducing medical costs, reducing pain, and reducing chronic edema

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

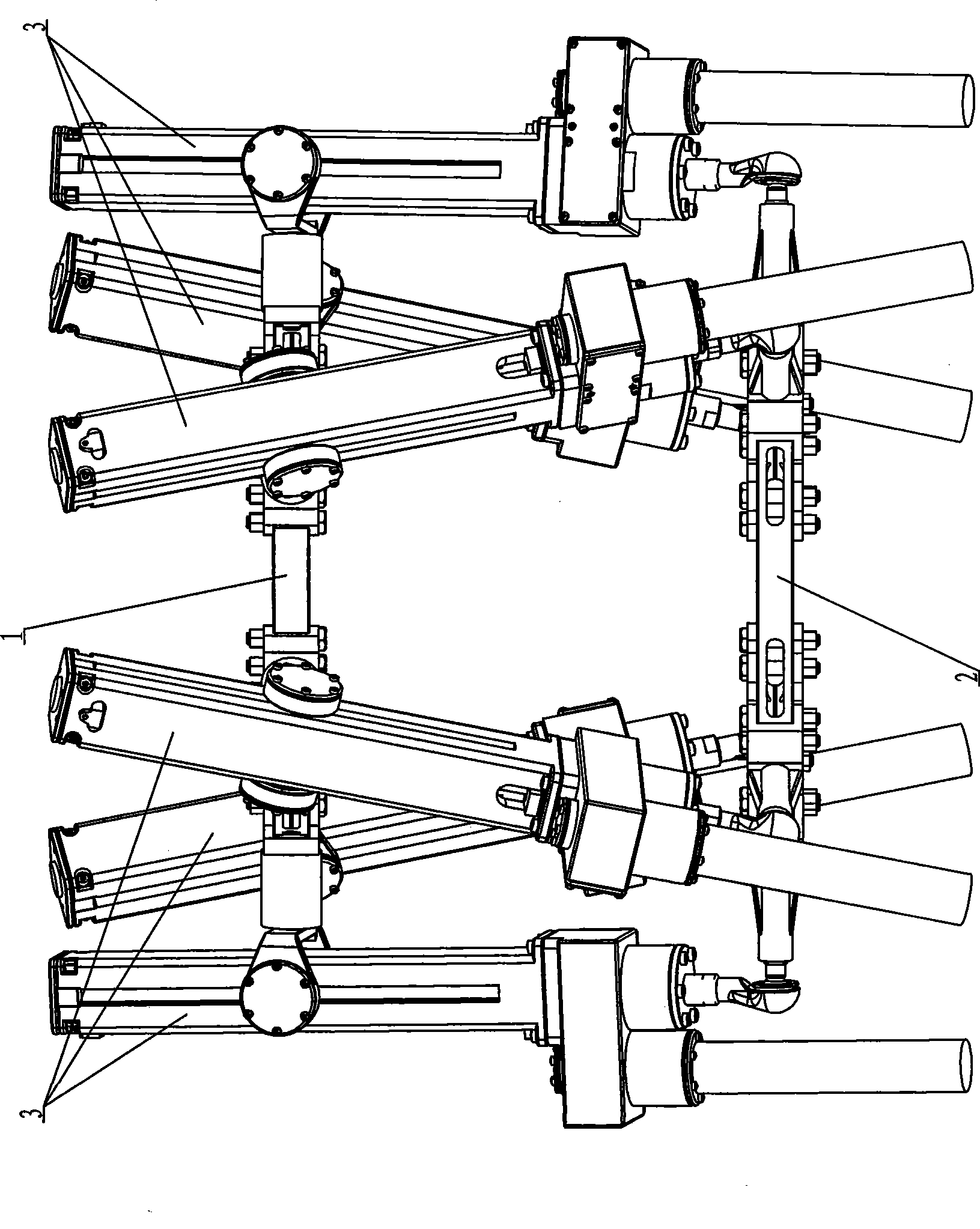

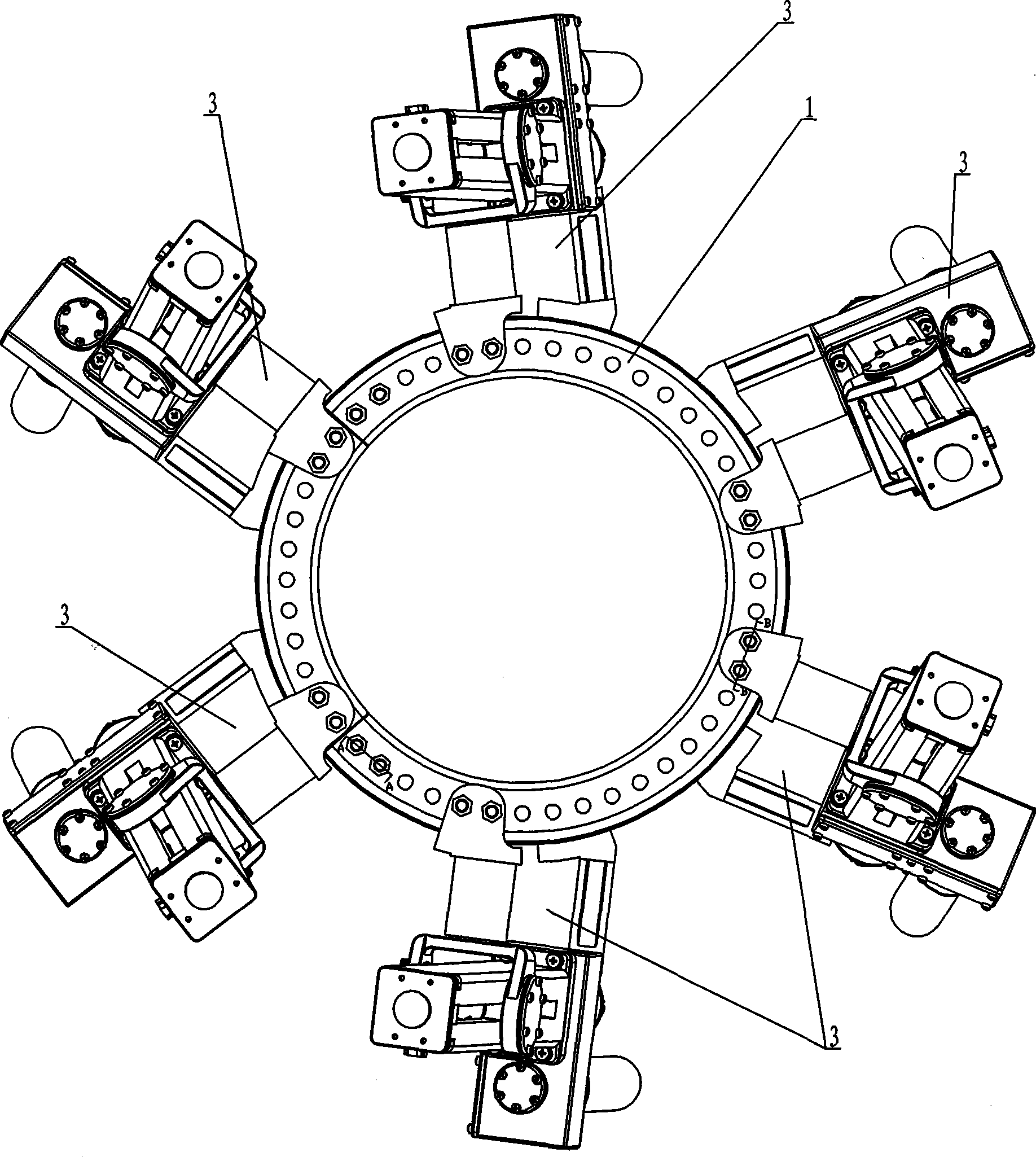

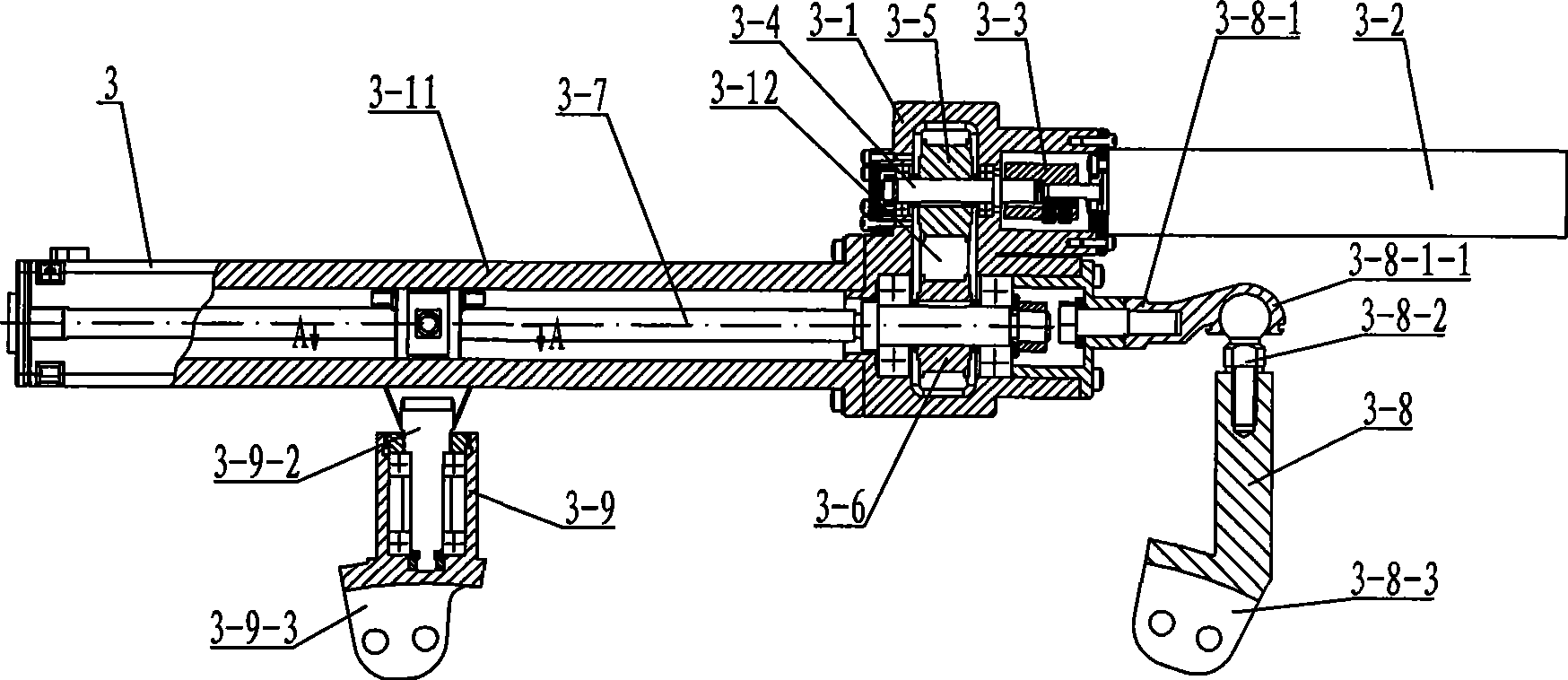

[0007] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment. This embodiment is composed of a moving ring 1, a fixed ring 2 and at least three branch chains 3, and each branch chain 3 consists of a reducer housing 3-1, a motor 3-2, and a coupling 3-3 , connecting shaft 3-4, driving pulley 3-5, passive pulley 3-6, lead screw 3-7, ball hinge mechanism 3-8, Hooke hinge 3-9, nut 3-10, lead screw housing 3-11 and belt 3-12, the connecting shaft 3-4 is hinged in the reducer housing 3-1 through the bearing, the input end of the connecting shaft 3-4 is connected with the output of the motor 3-5 through the coupling 3-3 Shaft connection, the driving pulley 3-5 is set on the connecting shaft 3-4, the driving pulley 3-5 is connected with the passive pulley 3-6 through the belt 3-12, and the passive pulley 3-6 is set on the screw 3- 7, the screw 3-7 is hinged in the reducer housing 3-1 through the bearing, the screw 3-7 is installed in the screw housin...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination image 3 and Figure 6 Describe this embodiment, the Hooke hinge 3-9 of this embodiment is made up of two Hooke hinge clamps 3-9-1, Hooke hinge clamp handle 3-9-2 and Hooke hinge mounting block 3-9-3 , the two Hooke hinge clamps 3-9-1 are symmetrically arranged and connected with the upper end of the Hooke hinge handle 3-9-2, and the lower end of the Hooke hinge handle 3-9-2 is hinged on the Hooke hinge through bearings In the block 3-9-3, the axis of the Hooke hinge mounting block 3-9-3 is perpendicular to the axes of the two Hooke hinge clamps 3-9-1. The two Hooke hinge clips 3-9-1 are fixedly connected with the nuts 3-10 through bolts respectively, and the lower end of the Hooke hinge mounting block 3-9-3 is fixedly mounted on the moving ring 1 through bolts. The Hooke hinge mounting block 3-9-3 can rotate arbitrarily around its axis, and the Hooke hinge clamp 3-9-1 cannot rotate.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination image 3 Describe this embodiment, the ball joint mechanism 3-8 of this embodiment is made up of ball joint mounting plate 3-8-1, ball joint 3-8-2 and ball joint connecting plate 3-8-3, ball joint mounting plate 3 One end of -8-1 is fixed on the reducer housing 3-1, the other end of the ball hinge mounting plate 3-8-1 is provided with a ball hinge shell 3-8-1-1, and the ball hinge 3-8-2 The ball end of the ball joint is hinged in the ball joint shell 3-8-1-1, and the handle end of the ball joint 3-8-2 is threadedly connected with the ball joint connecting plate 3-8-3. The other end of the ball hinge connecting plate 3-8-3 is fixedly mounted on the fixed ring 2 by bolts. The spherical hinge 3-8-2 can rotate freely on the axis of the spherical hinge connecting plate 3-8-3, and the range of motion of the axis of the spherical hinge connecting plate 3-8-3 is a ball center on the spherical hinge 3-8-2 A cone with vertices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com