Thermosetting epoxy asphalt material, preparation method and its dedicated compatibilizer

An epoxy asphalt material, thermosetting technology, applied in building insulation materials, melting and processing tar asphalt/petroleum asphalt/natural asphalt, building components, etc., can solve the problems that limit the promotion and application of thermosetting asphalt, achieve low cost and increase strength , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A thermosetting epoxy asphalt material compatibilizer, its structural formula is one of the following three:

[0051] Structural formula 1:

[0052]

[0053] Wherein, 13

[0054] Structural formula 2:

[0055]

[0056] Among them, 13

[0057] Structural formula 3:

[0058]

[0059] Wherein, 13<m<21 can be selected as 14,15,16,17,18,19,20, A is an epoxy resin group, B is a polyhydric alcohol group, and a high-level aliphatic carbon chain group (in the above formula Except for the remaining part of the A and B groups) and the polyol group (B) are respectively connected with two active groups of the epoxy resin (B).

[0060] The epoxy resin group described in this embodiment refers to epoxy resin as a substituent group, and other meanings are similar.

[0061] In the present embodiment, the epoxy resin (group A) in the structural for...

Embodiment 2

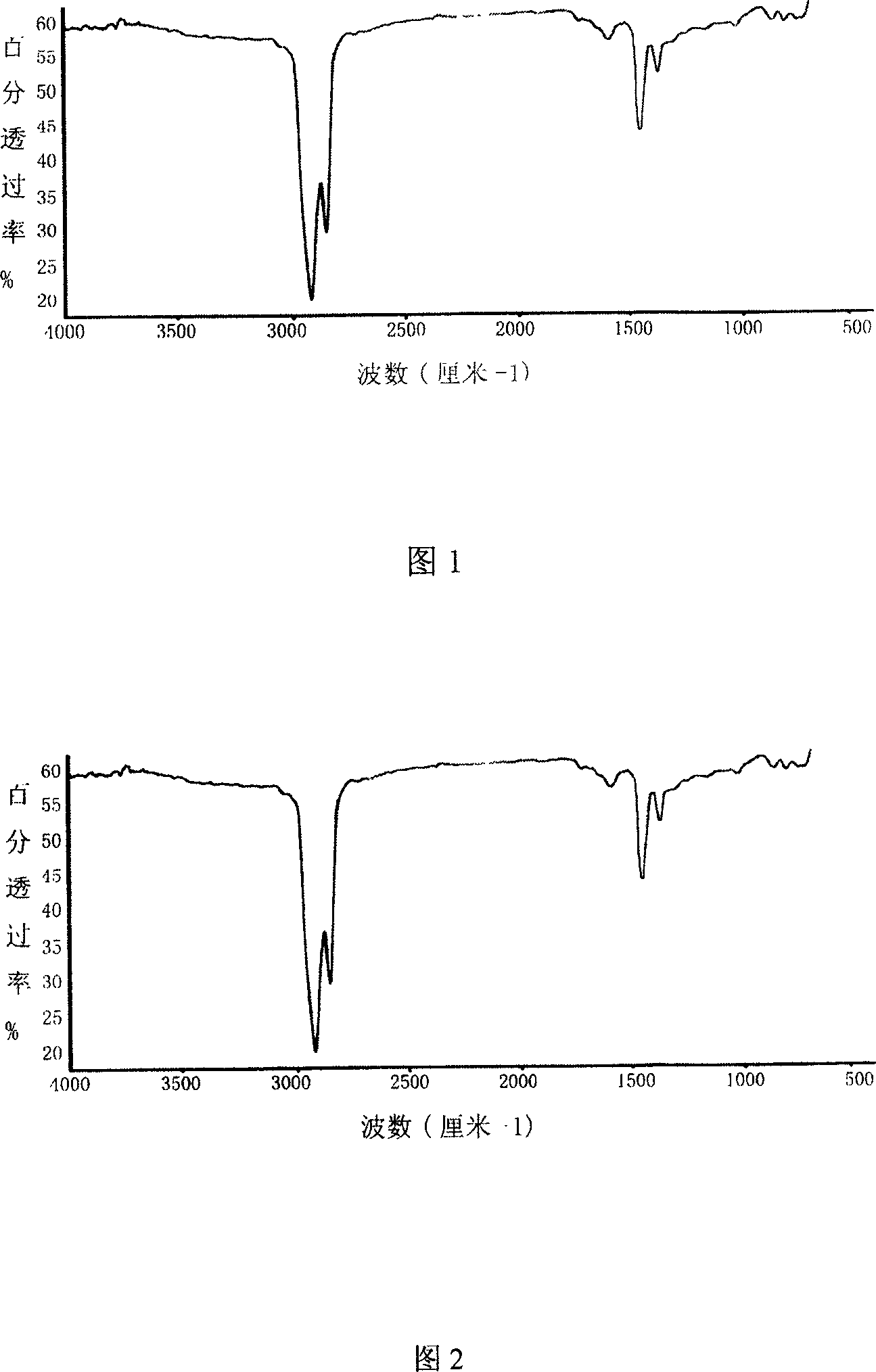

[0063] A preparation method of a thermosetting epoxy asphalt material, compatibilizing 100 parts by weight of pitch, 20-40 parts by weight of epoxy resin, 20-40 parts by weight of curing agent and 20-60 parts by weight of thermosetting epoxy asphalt material The mass fraction of the epoxy resin can be selected as 25 parts, 29 parts, 35 parts, and 38 parts, and the mass fraction of the curing agent can be 22 parts, 28 parts, 32 parts, and 37 parts. The thermosetting epoxy asphalt material The mass parts of the compatibilizer can be selected as 25 parts, 32 parts, 38 parts, 43 parts, 50 parts, 55 parts, heated to 80-90 °C, the temperature can be selected as 83 °C, 85 °C, 88 °C, and stirred evenly , and then cured at 100-120°C for 0.5-7 hours, the curing temperature can be selected as 105°C, 110°C, 115°C, and the curing time can be selected as 6.5 hours, 5 hours, 4 hours, 3 hours, 2 hours, 1 hour , 0.8 hour, get thermosetting epoxy asphalt material, in the present embodiment, can...

Embodiment 3

[0071] Mix 100 grams of Shell No. 90 asphalt, 40 grams of epoxy resin E-44, 30 grams of methyl tetrahydrophthalic anhydride and 30 grams of compatibilizer, heat to 90 ° C and stir evenly, put it in an oven at 120 ° C for 7 hours to obtain thermosetting Epoxy asphalt material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com