Patents

Literature

32results about How to "Weak polarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

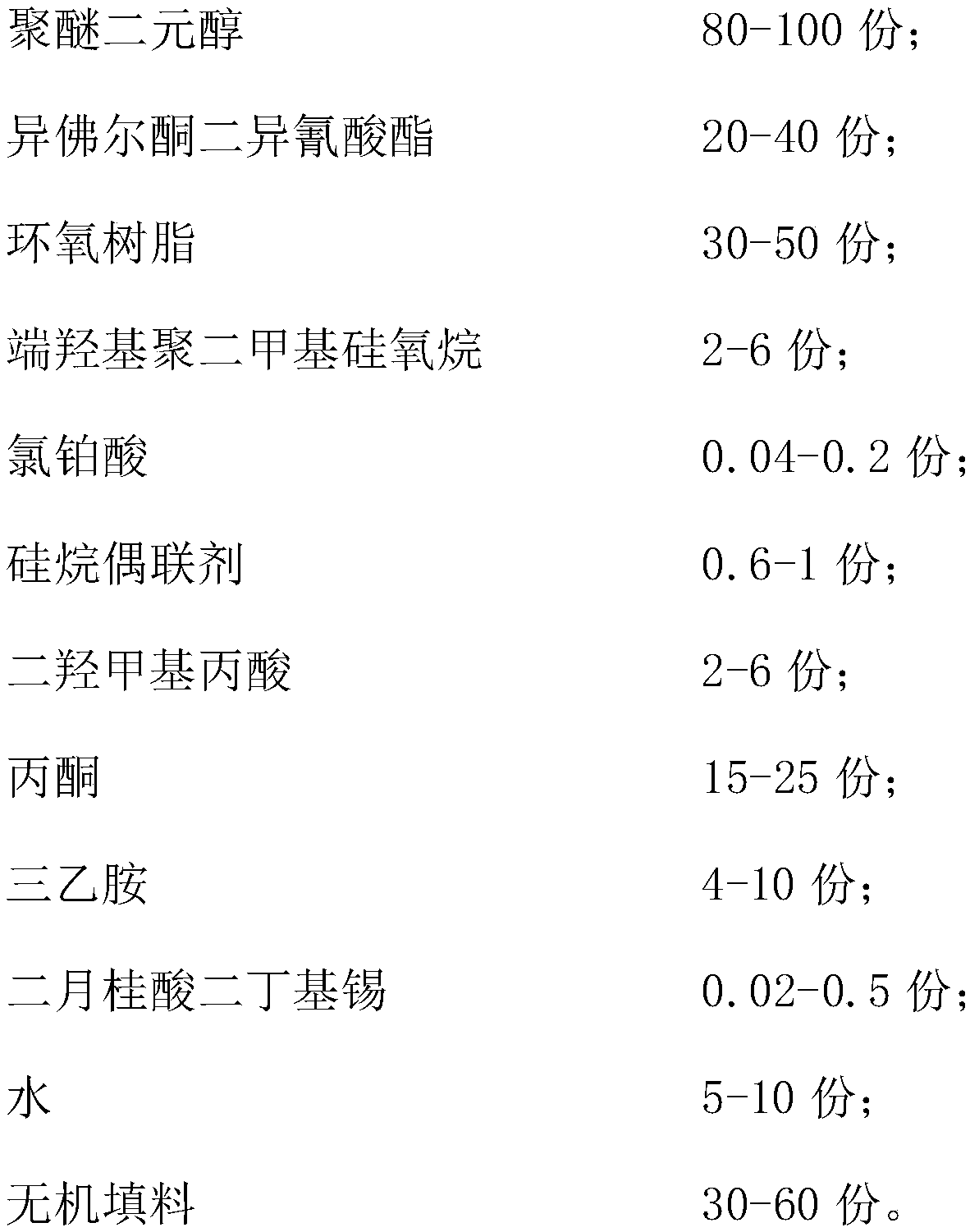

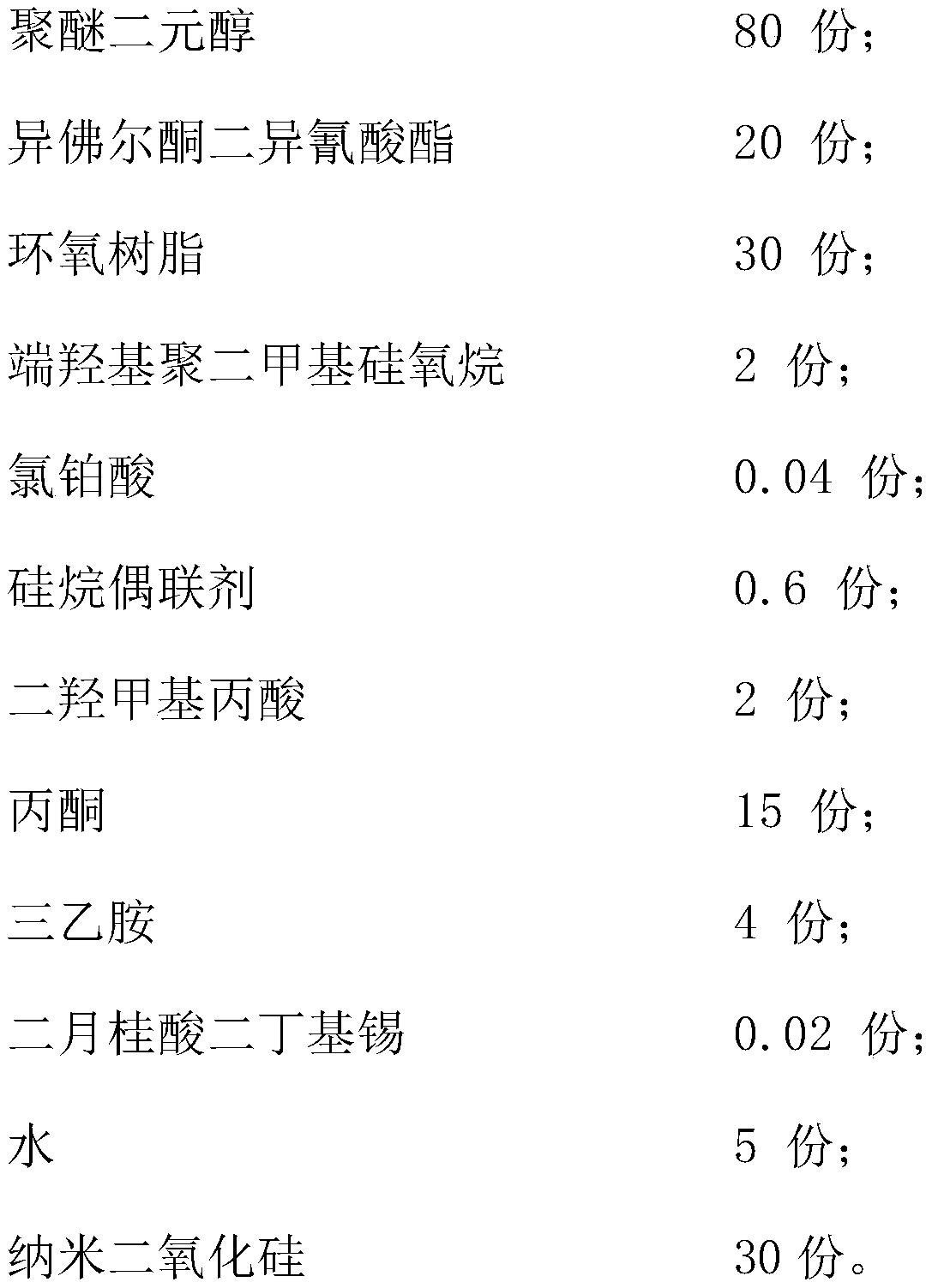

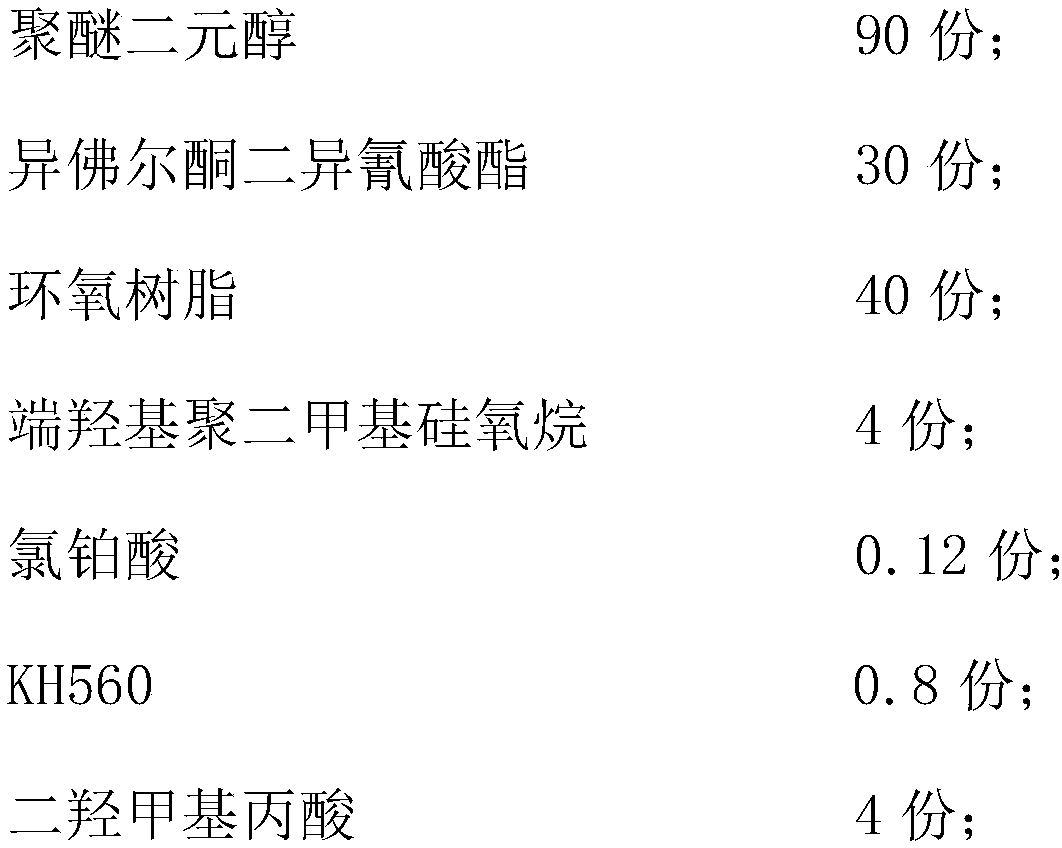

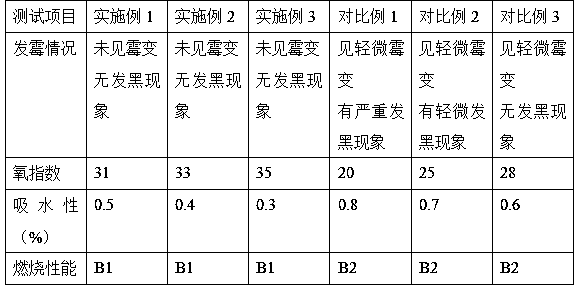

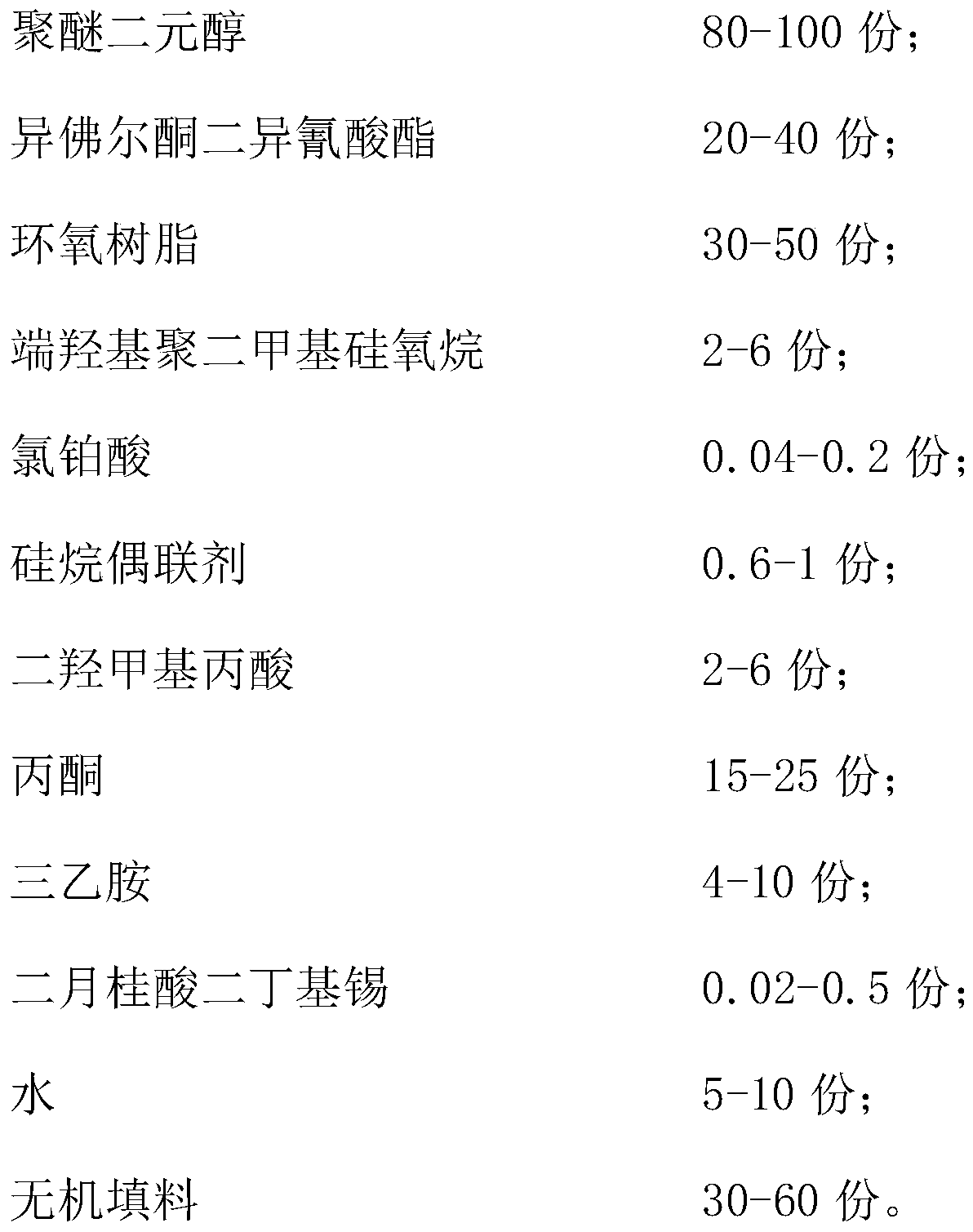

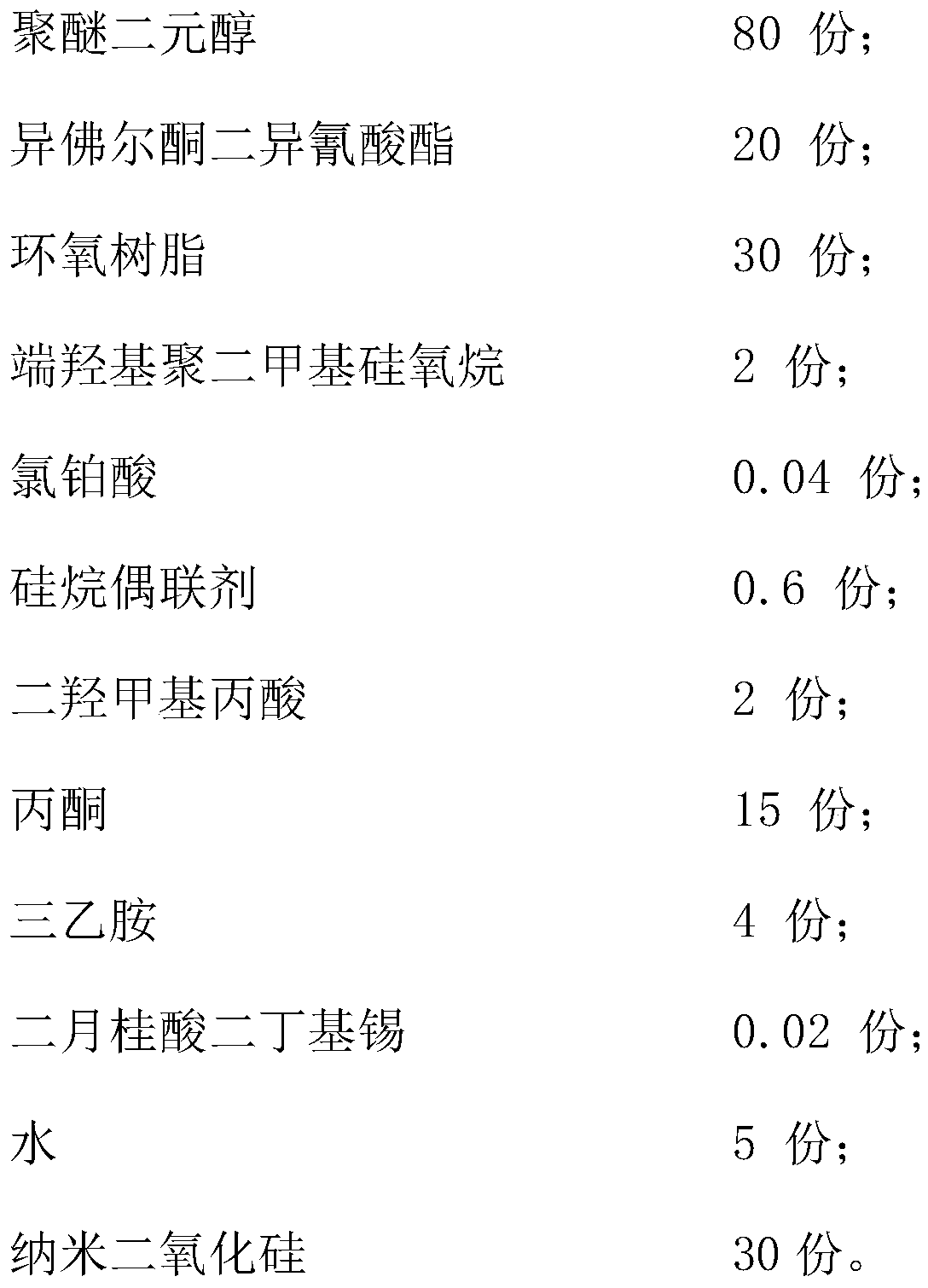

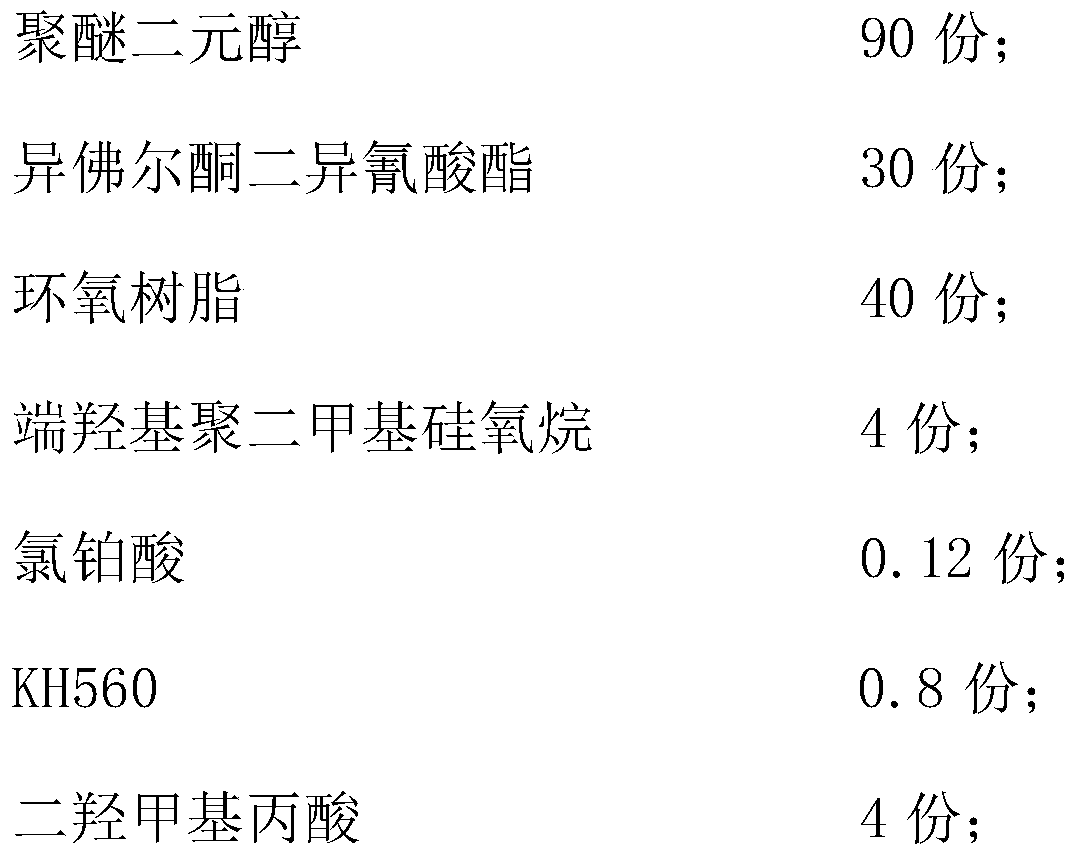

Epoxy-resin-modified polyurethane waterproof paint and preparation method thereof

ActiveCN108707414AReduce polarityWeak polarityPolyurea/polyurethane coatingsEpoxyIsophorone diisocyanate

The invention discloses epoxy-resin-modified polyurethane waterproof paint and a preparation method thereof. The epoxy-resin-modified polyurethane waterproof paint comprises the following components according to the parts by weight: 80-100 parts of polyether glycol, 20-40 parts of isophorone diisocyanate, 30-50 parts of an epoxy resin, 2-6 parts of hydroxy-terminated poly-dimethylsiloxane, 0.04-0.2 parts of chloroplatinic acid, 0.6-1 part of a silane coupling agent, 2-6 parts of dimethylolpropionic acid, 15-25 parts of acetone, 4-10 parts of trimethylamine, 0.02-0.5 parts of dibutyltin dilaurate, 5-10 parts of water, and 30-60 parts of inorganic filler. The preparation method comprises the following steps: S1: modifying the epoxy resin; S2: under the protection of nitrogen in 65-75 DEG C,performing a nucleophilic addition reaction of the polyether glycol; S3: in 70 DEG C, copolymerizing reaction products in the steps S1 and S2 and the dimethylolpropionic acid; and S4: neutralizing andhomogenizing. The epoxy-resin-modified polyurethane waterproof paint is capable of using the mutual crosslinking modification of polydimethylsiloxane, the epoxy resin and polyurethane, synthesizing the advantages of three parties, and improving the structure stability and the mechanical property of a coating film. The produced polyurethane waterproof paint can be tightly adhered to a non-polar base plane, and excellent in waterproof anti-penetrability performance.

Owner:ANHUI LENCAQI BUILDING MATERIAL

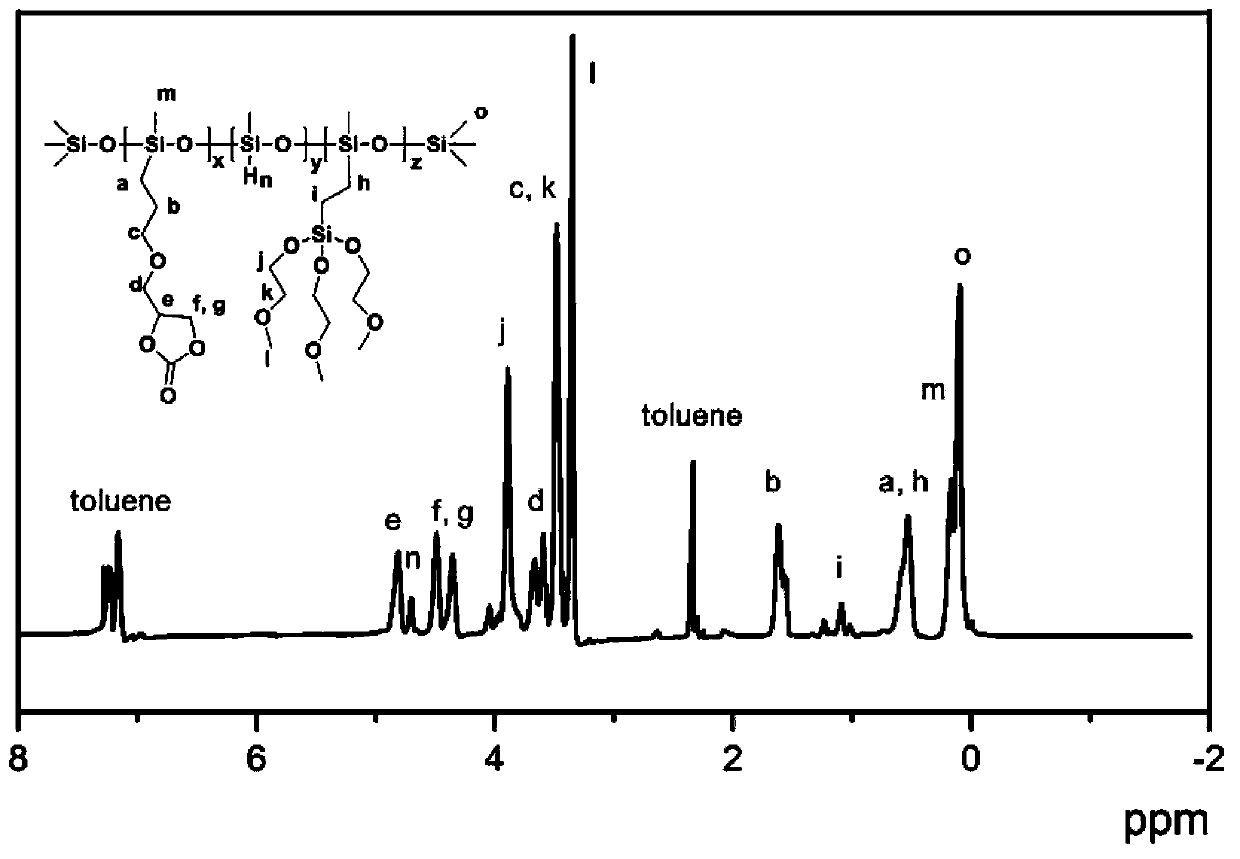

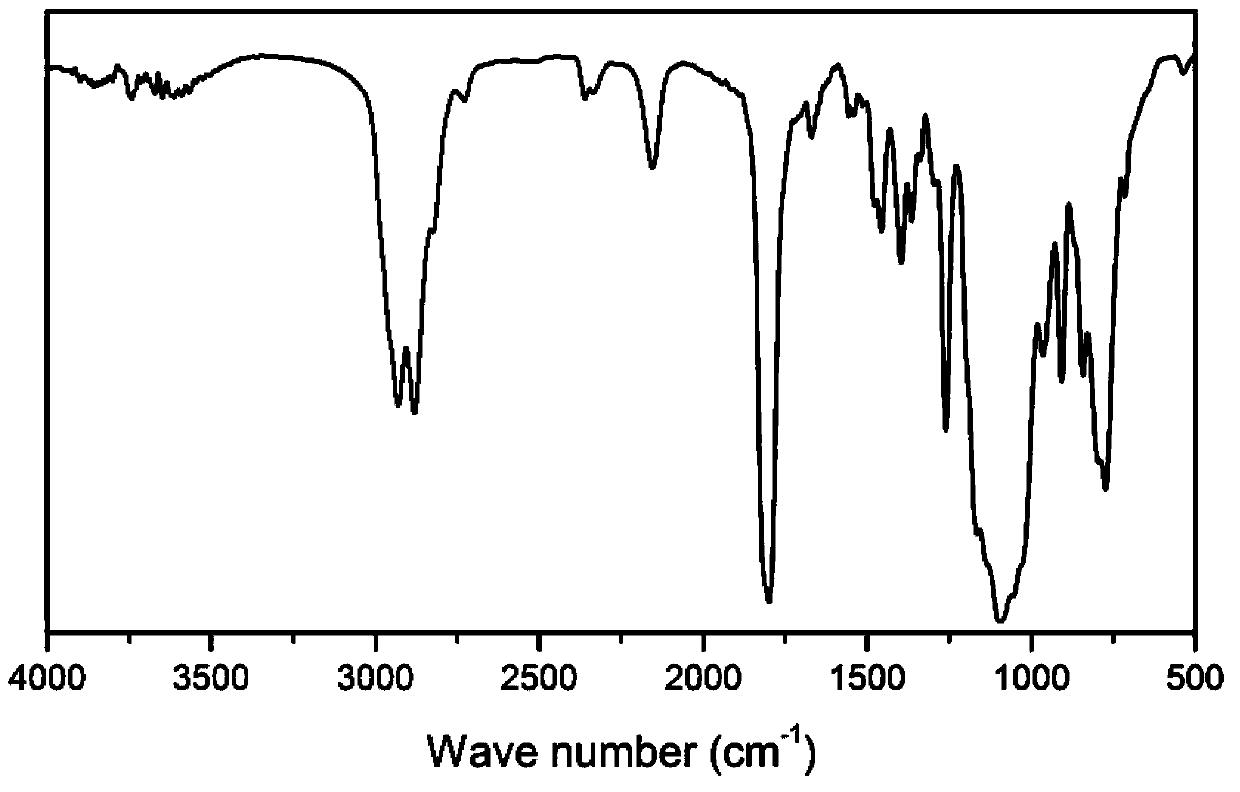

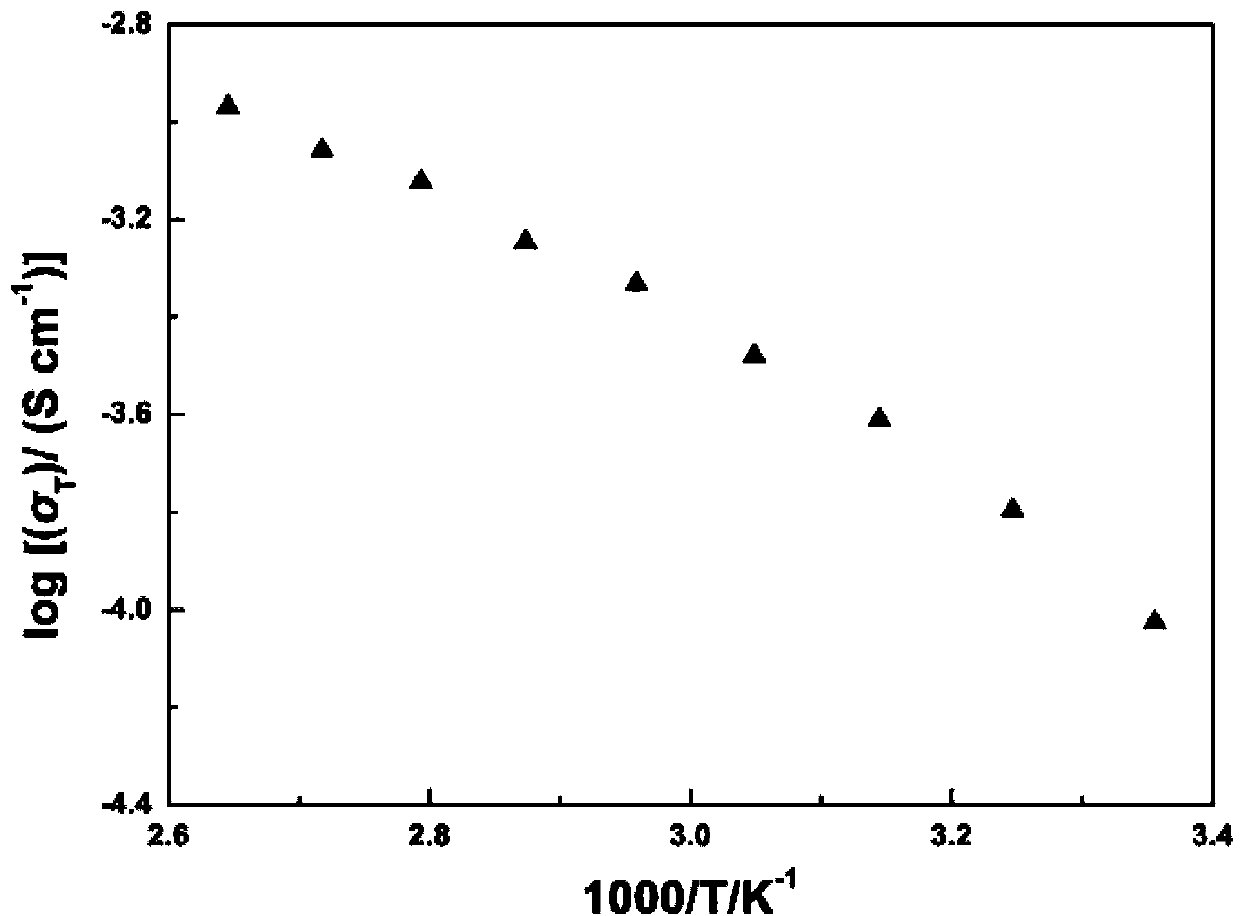

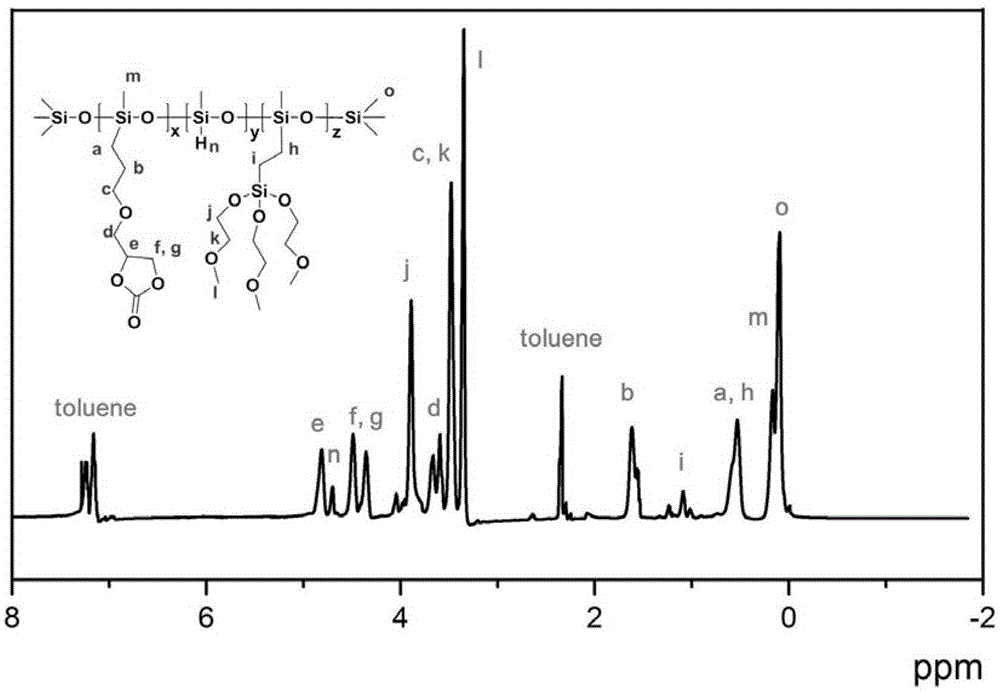

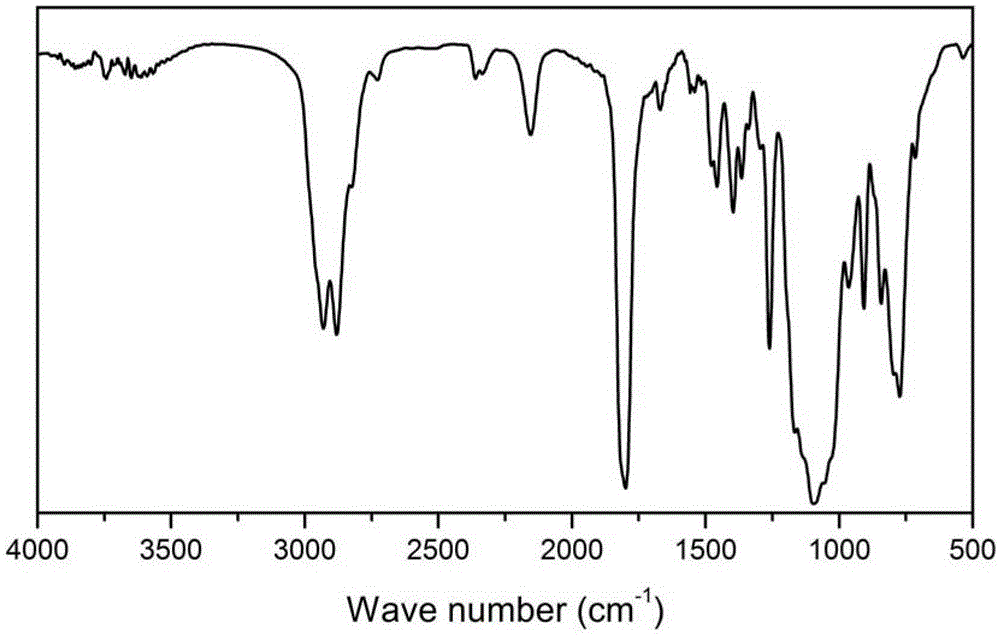

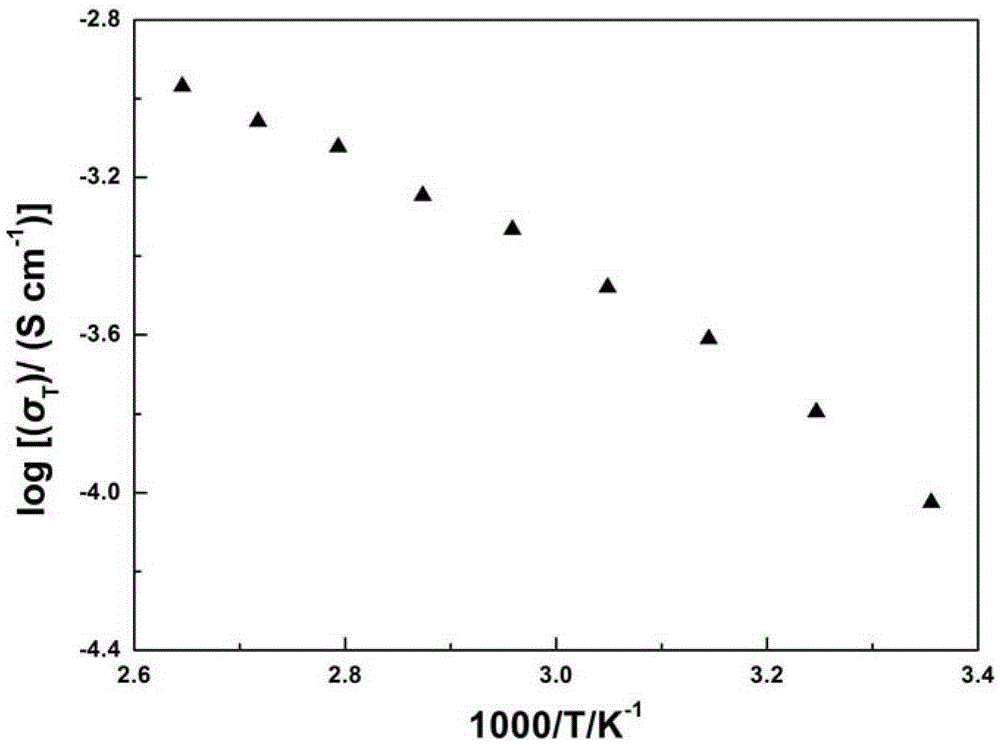

Comb polysilicone and solid electrolyte, preparation method and application thereof

ActiveCN103421190AExcellent mechanical propertiesFacilitate dissociationSecondary cellsElectricityHydrogen

The invention discloses a comb polysilicone and solid electrolyte, a preparation method and application thereof. Through additive reaction of polymethyl hydrogen siloxane with olefinic hydrocarbon, an alkoxysilane group and a carbonic ester group are led onto a branch chain, and the comb polysilicone is prepared. The preparation method is simple and the cost is low; the solid electrolyte prepared by taking the comb polysilicone as main raw material is high in electric conductivity at a low temperature, the electric cycling performance of the prepared all solid lithium ion battery is excellent, and the select range and the application field of the solid electrolyte material are expanded.

Owner:王海斌

Carbon coating method for non-carbon anode materials

ActiveCN109192970AImprove uniformitySpread evenlyNegative electrodesSecondary cellsCarbon coatingMaterials preparation

The invention provides a carbon coating method of a non-carbon negative electrode material, which relates to the technical field of material preparation. The carbon coating method of the non-carbon negative electrode material comprises the following steps: (A) a first carbon layer is coated on the surface of the non-carbon negative electrode material by a vapor phase coating method to obtain a precursor; B) coat a second carbon layer on that surface of the precursor by a liquid-phase coat method to complete the carbon coating of the non-carbon negative electrode material. The carbon coating method can alleviate the technical problem that the uniformity of the carbon coating layer is poor when the liquid phase coating method is directly used for the carbon coating of the non-carbon negativeelectrode material.

Owner:SOUNDON NEW ENERGY TECH CO LTD

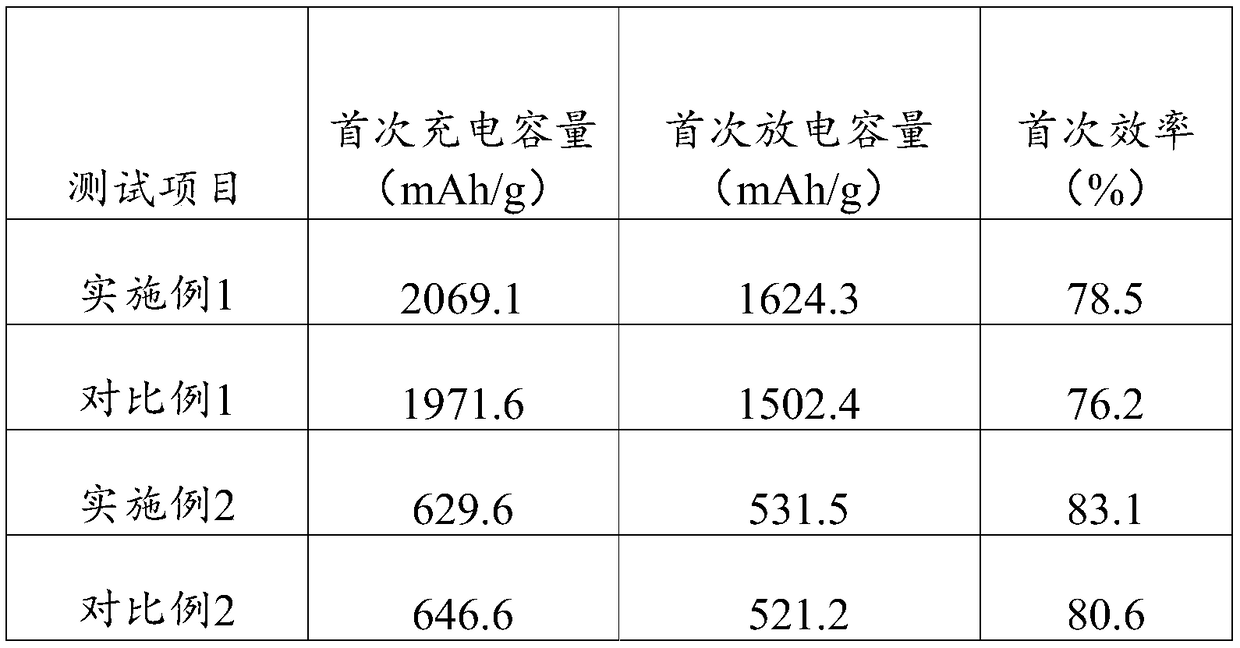

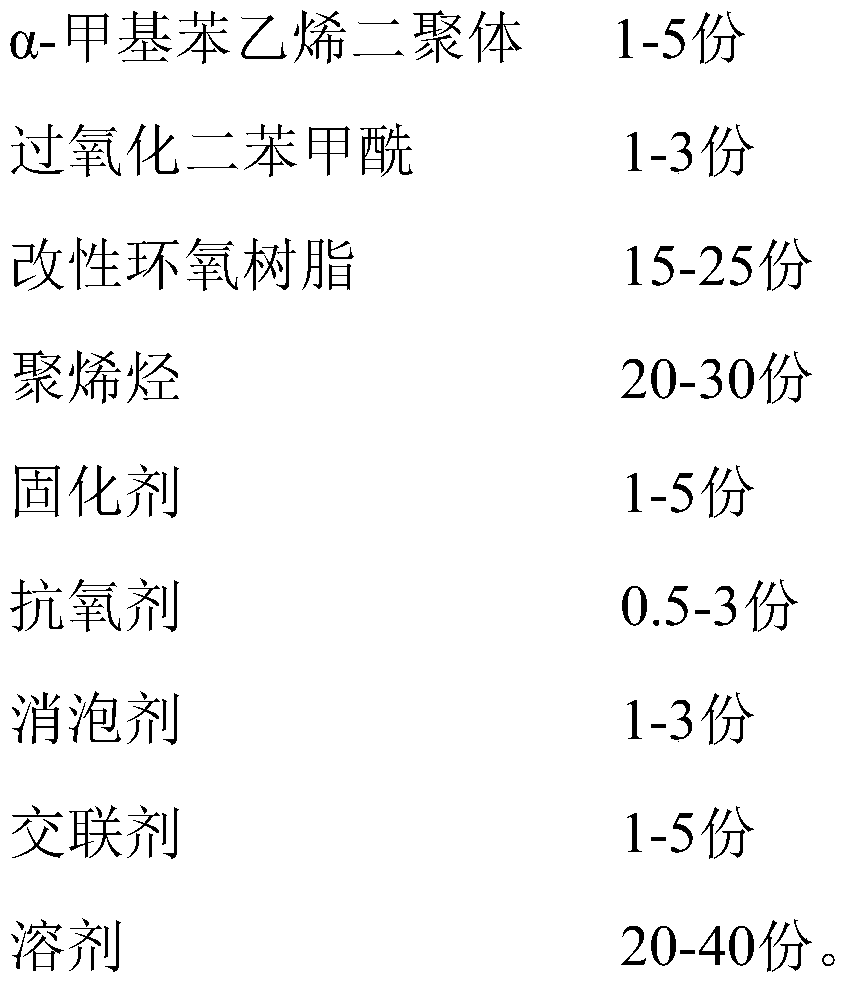

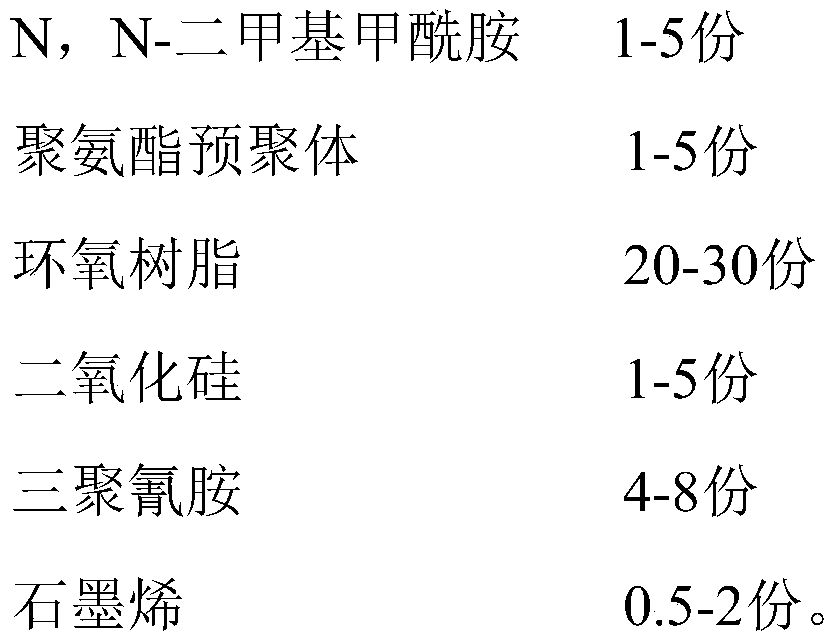

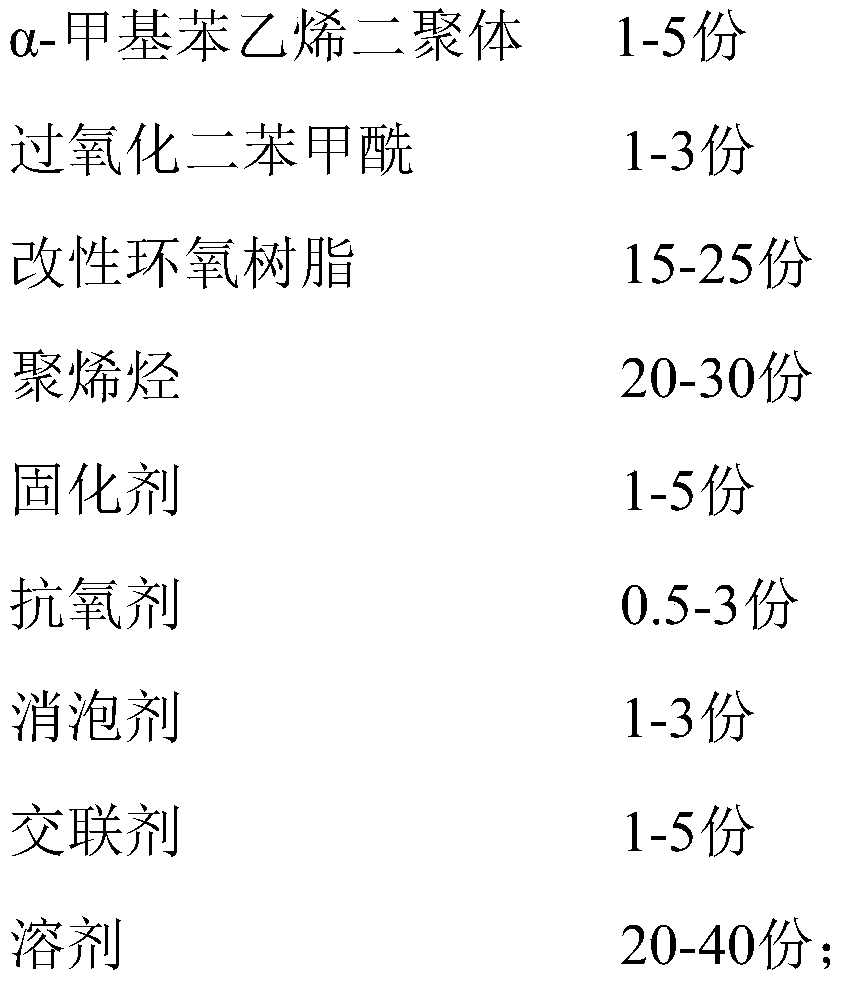

Aluminum-plastic film for packaging lithium battery and preparation method thereof

ActiveCN111572135AImprove barrier propertiesImprove ductilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberPolyolefin

The invention relates to the technical field of soft package materials for lithium battery packaging, particularly to an aluminum-plastic film for lithium battery packaging and a preparation method thereof. The aluminum-plastic film comprises a polyurethane fiber layer, an aluminum foil layer and a polypropylene heat-sealing layer from top to bottom, wherein the aluminum foil layer is attached tothe polypropylene heat sealing layer; polyurethane fibers are attached to the aluminum foil layer; the polyurethane fiber layer and the aluminum foil layer are bonded through a modified polyolefin adhesive; and the aluminum foil layer and the polypropylene heat-sealing layer are bonded through a polyurethane adhesive. The modified polyolefin adhesive is prepared from the following raw materials inparts by weight: 1 to 5 parts of alpha-methylstyrene dimer, 1 to 3 parts of dibenzoyl peroxide, 15 to 25 parts of modified epoxy resin, 20 to 30 parts of polyolefin, 1 to 5 parts of a curing agent, 0.5 to 3 parts of an antioxidant, 1 to 3 parts of a defoaming agent, 1 to 5 parts of a cross-linking agent and 20 to 40 parts of a solvent. The aluminum-plastic film provided by the invention has excellent barrier property, ductility and corrosion resistance, and also has good heat-sealing sol aluminum leakage prevention effect.

Owner:JIANGXI MING CROWN LITHIUM MEMBRANE TECH CO LTD

Hybrid Supported Metallocene Catalyst, Method for Preparing the Same, and Process for Preparing Polyolefin Using the Same

ActiveUS20150025204A1Excellent catalytic activityWeak polarityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationIonPolyolefin

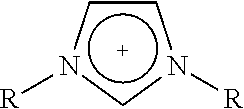

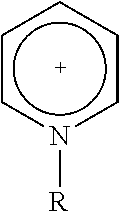

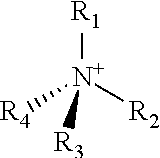

Provided are a hybrid supported metallocene catalyst, a method for preparing the same, and a process for preparing an olefin polymer using the same, and more particular, a hybrid supported metallocene catalyst characterized in that two kinds of metallocene compounds containing a new cyclopenta[b]fluorenyl transition metal compound are supported on an inorganic or organic porous carrier surface-treated with an ionic compound and a co-catalyst, a method for preparing the same, and a process for preparing an olefin polymer using the hybrid supported metallocene catalyst.

Owner:SK GEO CENTRIC CO LTD +1

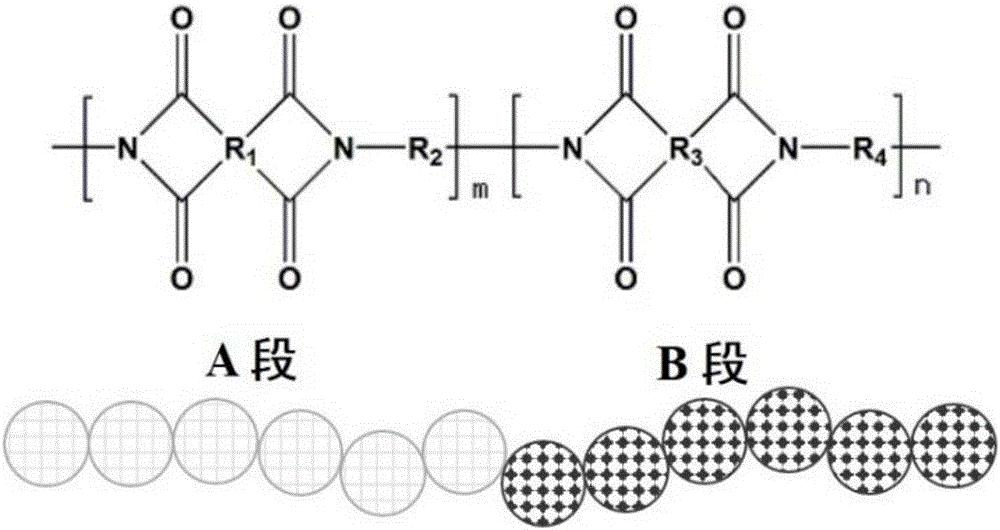

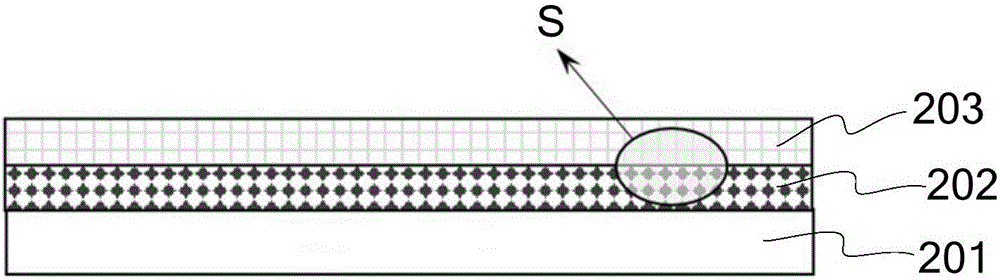

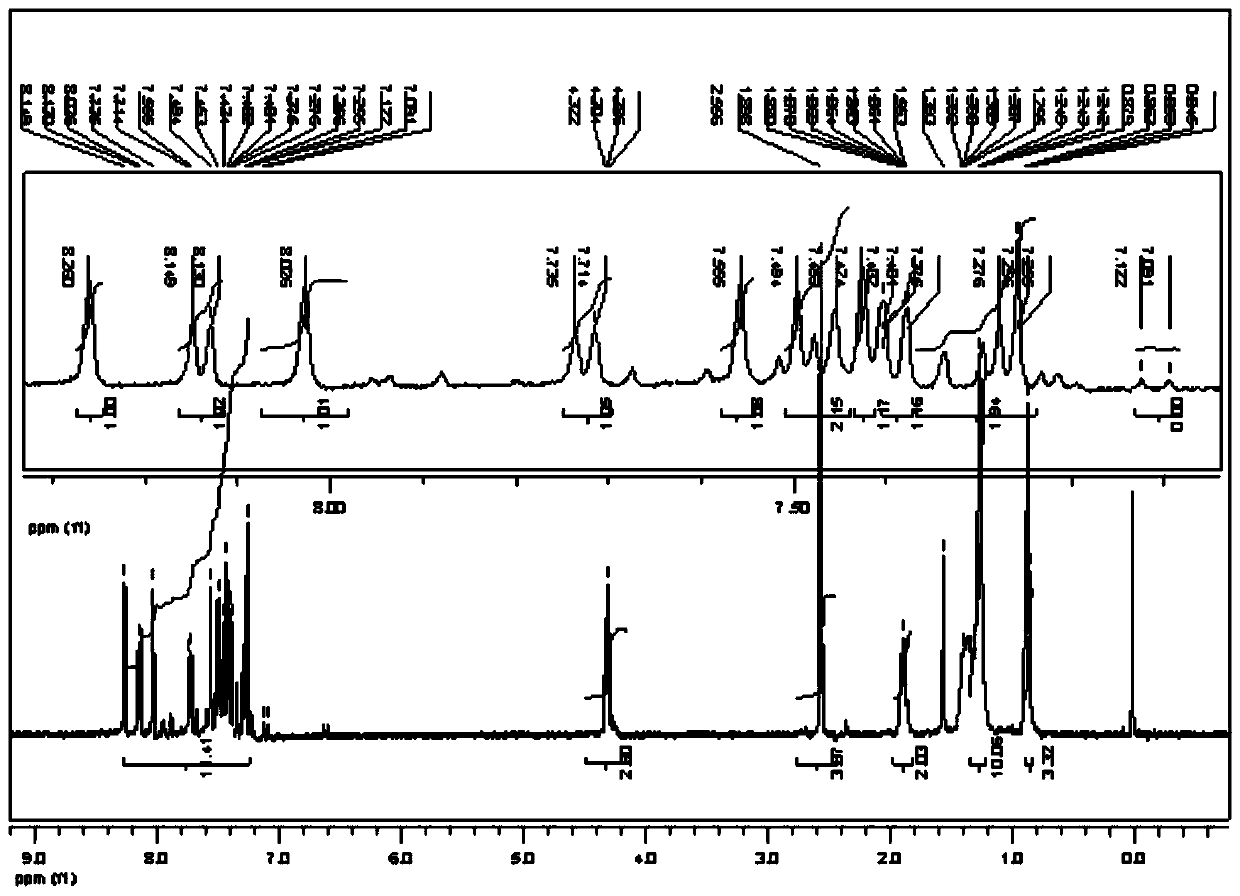

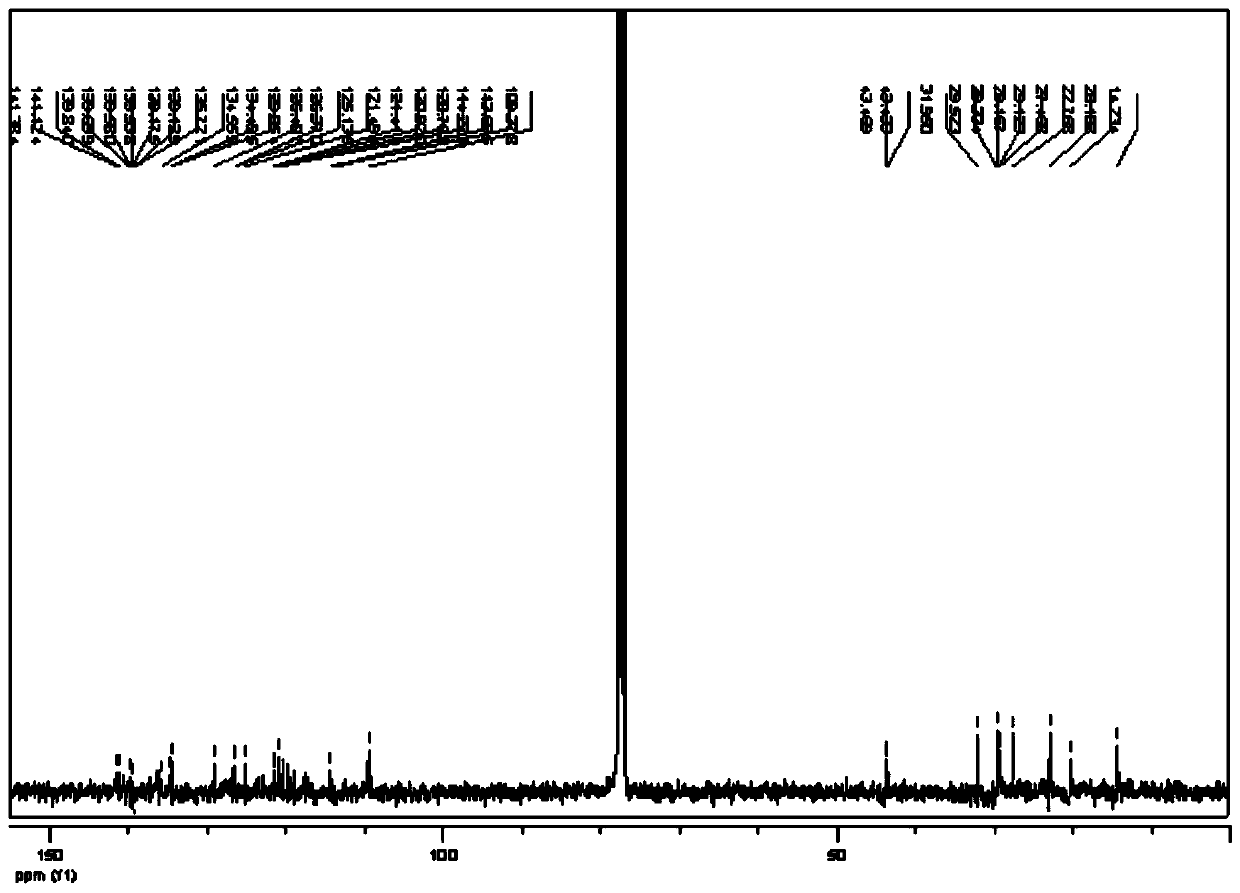

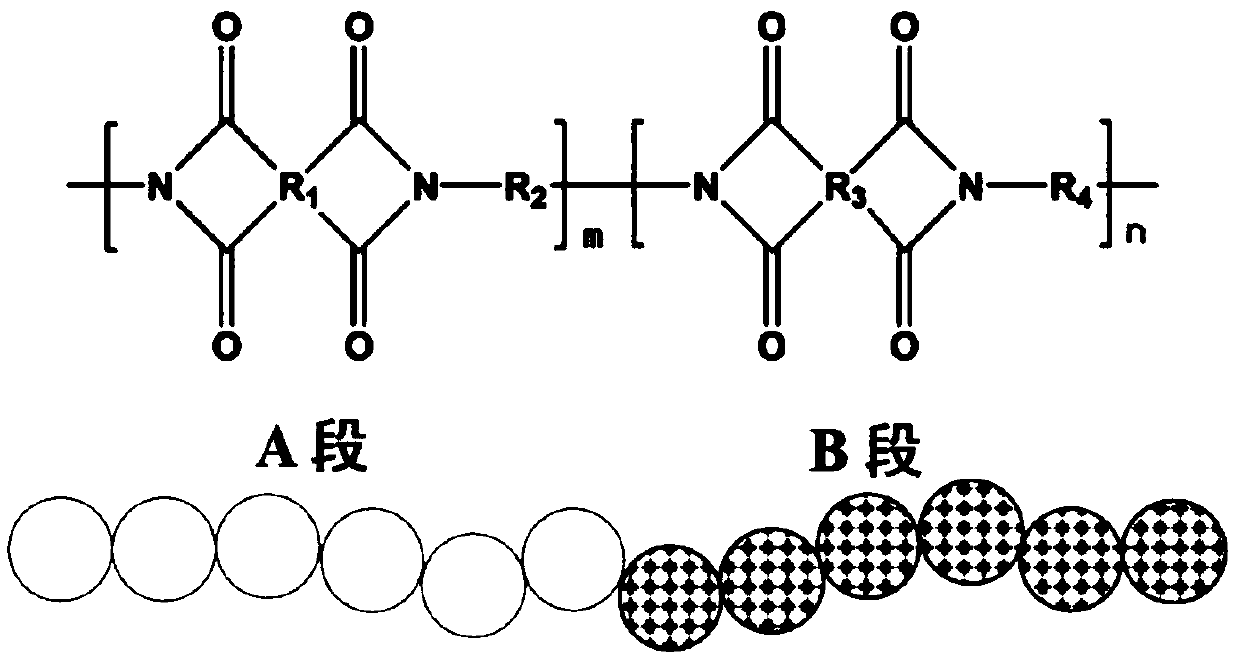

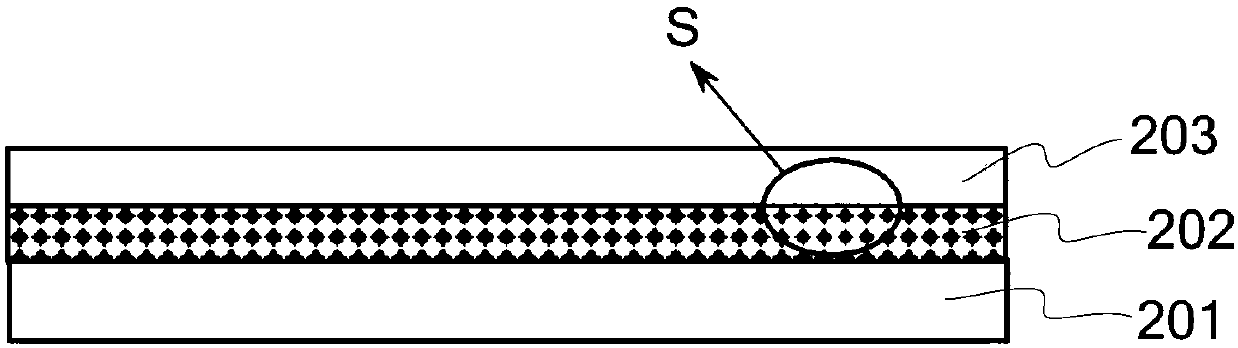

Preparing method of alignment film, displaying panel and displaying device

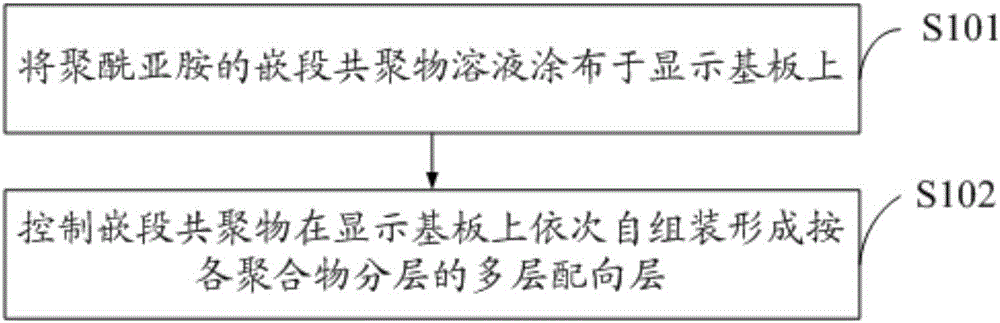

The invention discloses a preparing method of an alignment film, a displaying panel and a displaying device. The preparing method of the alignment film comprises the steps of coating a segmented copolymer solution of polyimide on a displaying basal plate, wherein the segmented copolymer is polymerized by two or more kinds of polymers with different polarities; controlling the segmented copolymer to conduct self-assembly in sequence on the displaying basal plate to form a multilayer alignment layer which is layered by various polymers, wherein the polarity of the alignment layer on each layer decreases progressively according to a sequence in which the distances of the alignment layers to the displaying basal plate are from near to far. According to the preparing method of the alignment film, the multilayer alignment film which has a remarkable layered interface can be obtained, the technique is simple, problems of a complex technique and easy introduction of ion impurities brought by using a layer-by-layer preparation to prepare a multiple alignment layer are avoided, in addition, the polarity of the alignment layer on each layer decreases progressively according to the sequence in which the distances of the alignment layers to the displaying basal plate are from near to far, thus preventing the ion impurities in the displaying basal plate from entering a liquid crystal layer.

Owner:BOE TECH GRP CO LTD +1

Nano metal ink and preparation method thereof

The invention relates to nano metal ink and a preparation method thereof. The nano metal ink is prepared from components in percentage by mass as follows: 3%-60% of conductive nano metal, 35%-94% of an organic solvent, 0.5%-15% of a stabilizer and 2%-40% of cycloalkane alcohol additives. The nano metal ink is prepared from organic acid with carbon atom number being 7-18 and / or organic amine as thestabilizer, the organic solvent and the cycloalkane alcohol additives by compounding, the viscosity range is 2 cP-10 cP, the surface tension is 25 mN / m-50 mN / m, and the nano metal ink is suitable forink-jet printing for film formation; the organic solvent, the stabilizer and the cycloalkane alcohol additives can be removed in a drying film formation process, residues are removed, the film formation is uniform, low-temperature sintering can be realized, volume resistivity is relatively low, and satellite points are avoided during ink-jet printing.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Preparation method of special formaldehyde-removing paint for furniture

The invention discloses a preparation method of a special formaldehyde-removing paint for furniture. The method comprises the steps of mixing polyalkylene imide, polypropylene glycol and a helical carbon fiber at the ratio and then preparing a formaldehyde trapping agent; mixing with water for ultrasonic dispersion, carrying out vacuum drying on a rotary evaporator and crushing the mixture into 500 meshes; and finally carrying out mix dispersion on the product and a wood coating, painting or spraying the paint on the surface of the furniture through a spray gun and drying and polishing. The special formaldehyde-removing paint for the furniture is excellent in purification effect due to the fact that the helical carbon fiber is low in molecular weight, relatively weak in polarity and over-large in specific surface area; the formaldehyde trapping agent is evenly dispersed into the paint, and paved on the surface of the furniture, so that the special formaldehyde-removing paint is large in absorption acting surface, short in absorption time, good in absorption effect and convenient to use.

Owner:贵州锦豪家具有限公司

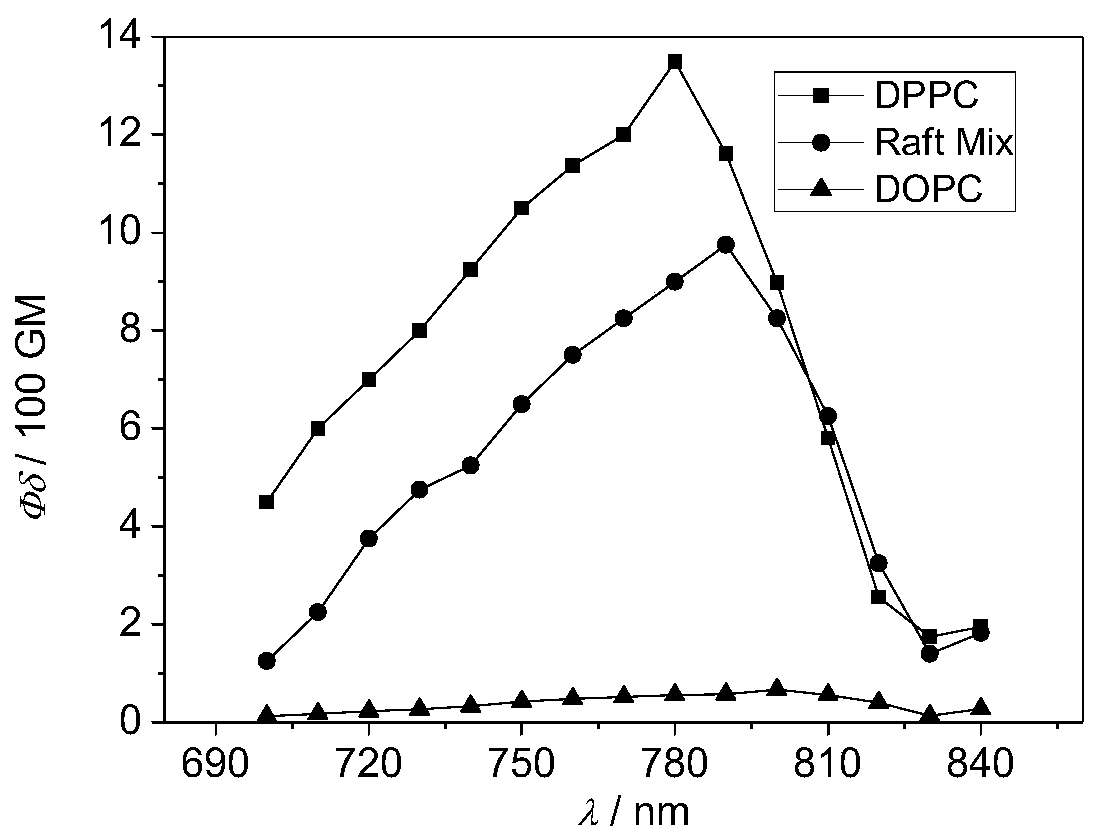

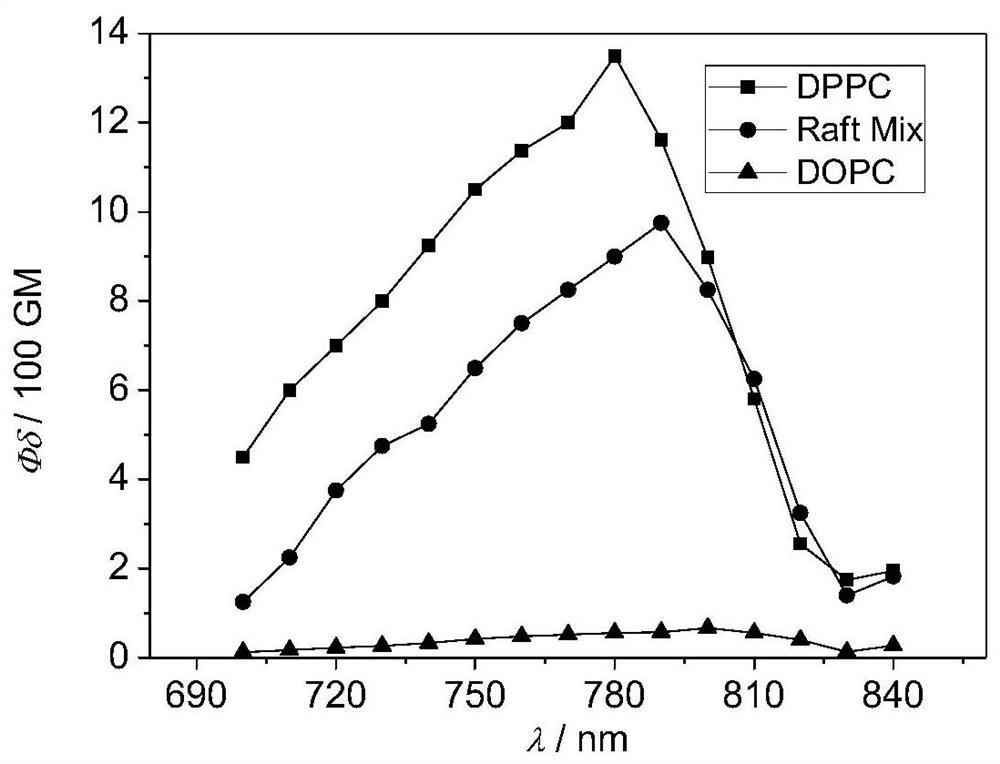

Application of dual-photon fluorescence probe

ActiveCN109946276AAvoid interferenceImprove accuracyOrganic chemistryFluorescence/phosphorescenceImage resolutionFluorescence

The invention relates to the technical field of the dual-photon fluorescence probe, and specifically relates to an application of the dual-photon fluorescence probe. The dual-photon fluorescence probeis applied to the cell and tissue imaging and used for detecting lipid raft content and distribution dynamic; the probe can improve the accuracy, precision, sensitivity and imaging resolution of thelipid raft detection, thereby providing a new thought for further preventing and controlling Alzheimer's disease and Prion Disease and like neurodegenerative diseases.

Owner:ZUNYI NORMAL COLLEGE

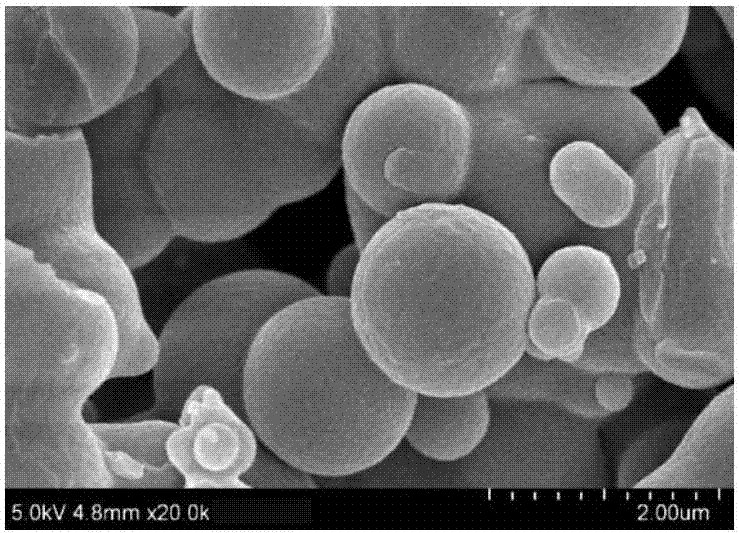

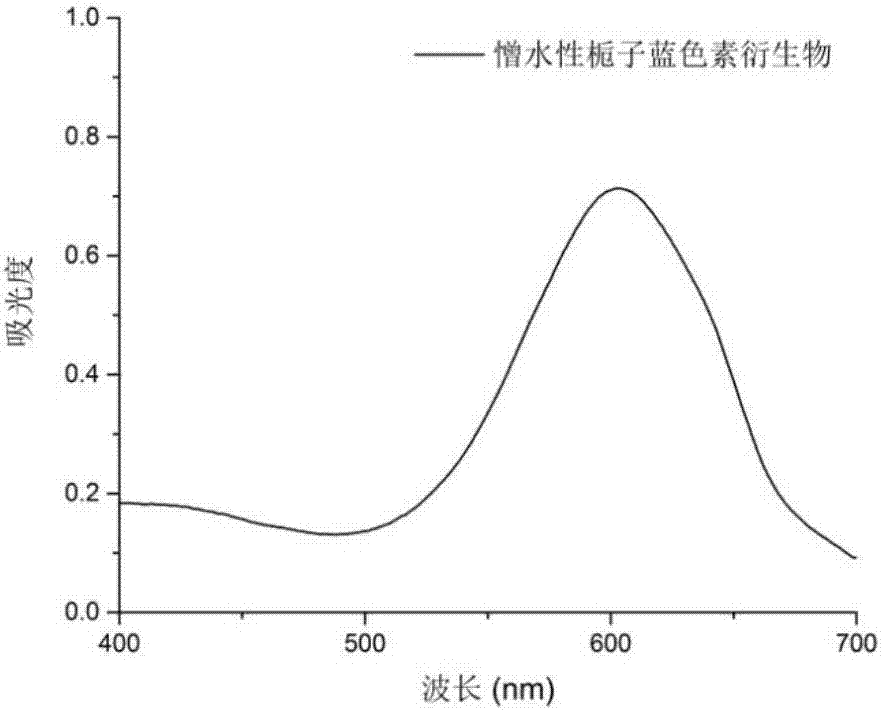

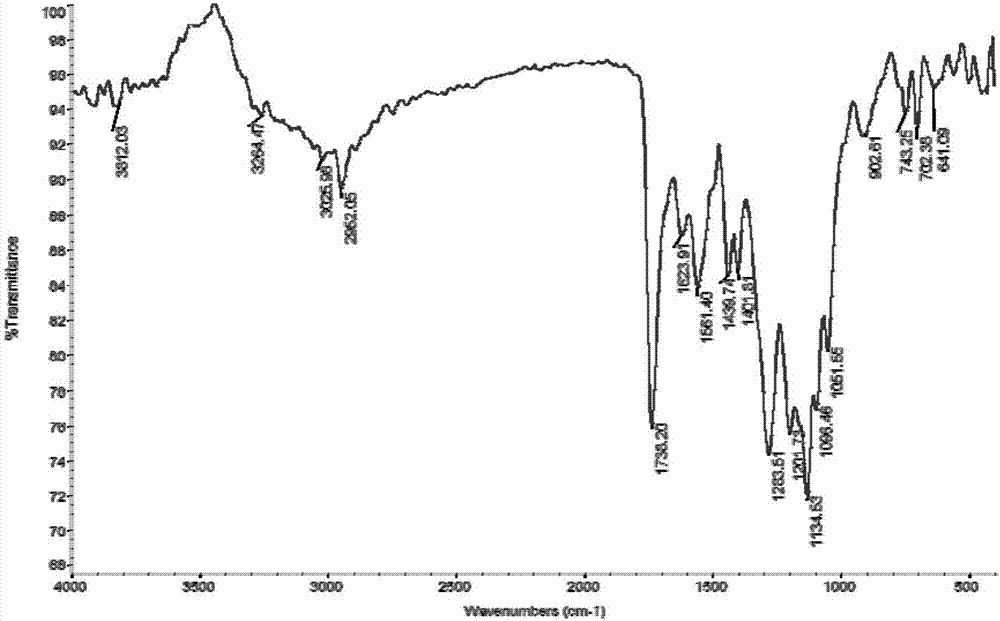

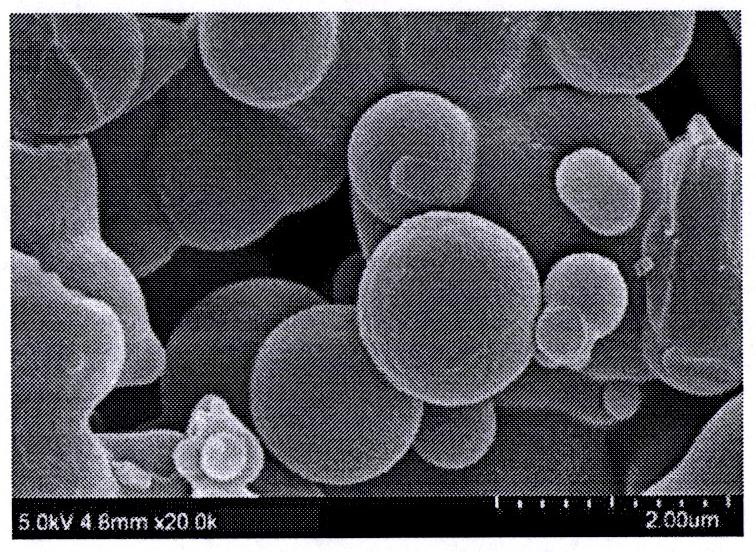

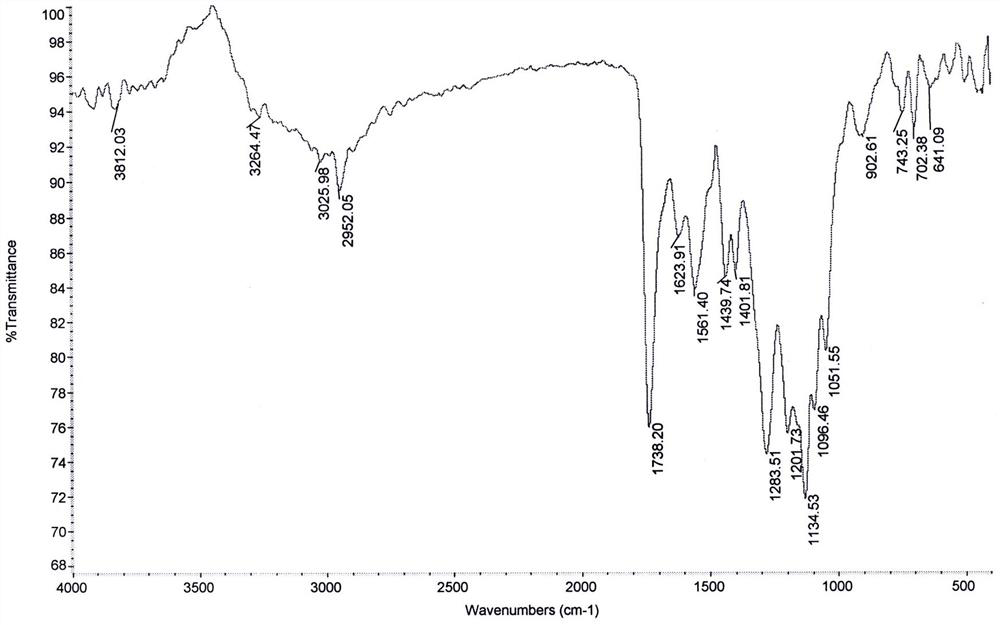

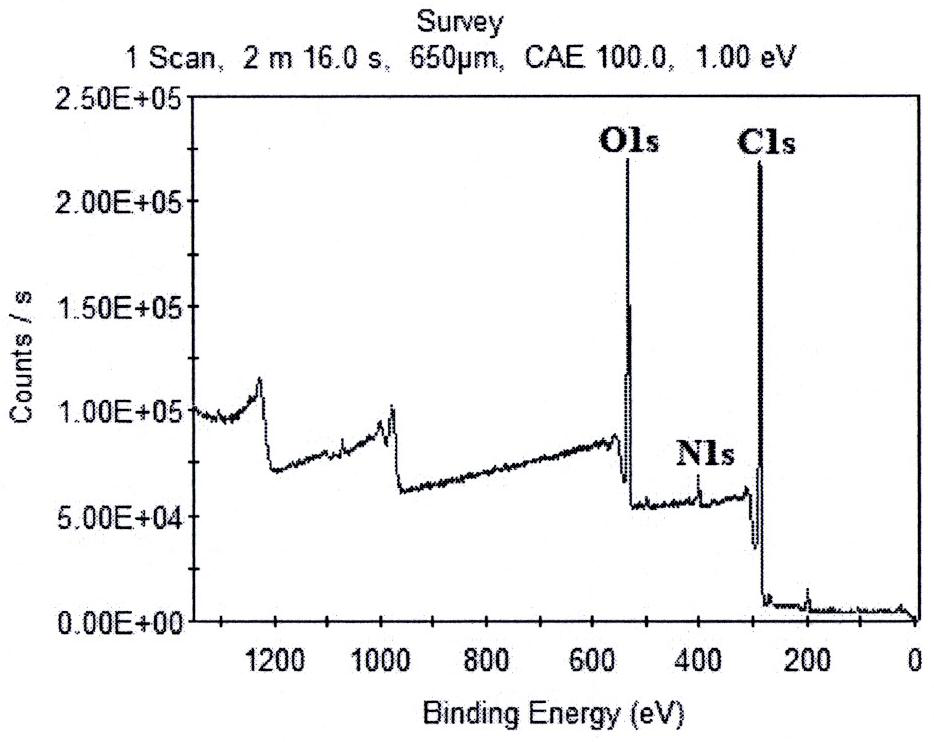

Liposoluble gardenia blue pigment and preparation method thereof

ActiveCN107973750AWeak polarityAvoid introducingCosmetic preparationsOrganic chemistryAlcoholGenipin

The invention relates to a liposoluble gardenia blue pigment and a preparation method thereof. The preparation method comprises the following steps of (1) weighing genipin and amino acid methyl esterhydrochloride, dissolving in ethyl alcohol, fully dissolving, and uniformly shaking; (2) putting in a shaking bath at the temperature of 40 DEG C to 70 DEG C, and carrying out normal pressure reactionat 150 to 220rpm with the existence of oxygen; (3) after finishing reaction, carrying out rotary evaporation to remove ethyl alcohol, and obtaining a liposoluble gardenia blue pigment crude product;(4) concentrating and purifying the a liposoluble gardenia blue pigment crude product, and obtaining a liposoluble gardenia blue pigment pure product. The liposoluble gardenia blue pigment is a mixture, is mainly shaped as a spherical particle, and has the particle size being around 100nm. The illumination and temperature stability of the liposoluble gardenia blue pigment is higher than the illumination and temperature stability of a water-soluble gardenia blue pigment.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

A method for manufacturing an alignment film, a display panel, and a display device

InactiveCN106444163BIncrease polarityWeak polarityNon-linear opticsElectrical polarityDisplay device

The invention discloses a preparing method of an alignment film, a displaying panel and a displaying device. The preparing method of the alignment film comprises the steps of coating a segmented copolymer solution of polyimide on a displaying basal plate, wherein the segmented copolymer is polymerized by two or more kinds of polymers with different polarities; controlling the segmented copolymer to conduct self-assembly in sequence on the displaying basal plate to form a multilayer alignment layer which is layered by various polymers, wherein the polarity of the alignment layer on each layer decreases progressively according to a sequence in which the distances of the alignment layers to the displaying basal plate are from near to far. According to the preparing method of the alignment film, the multilayer alignment film which has a remarkable layered interface can be obtained, the technique is simple, problems of a complex technique and easy introduction of ion impurities brought by using a layer-by-layer preparation to prepare a multiple alignment layer are avoided, in addition, the polarity of the alignment layer on each layer decreases progressively according to the sequence in which the distances of the alignment layers to the displaying basal plate are from near to far, thus preventing the ion impurities in the displaying basal plate from entering a liquid crystal layer.

Owner:BOE TECH GRP CO LTD +1

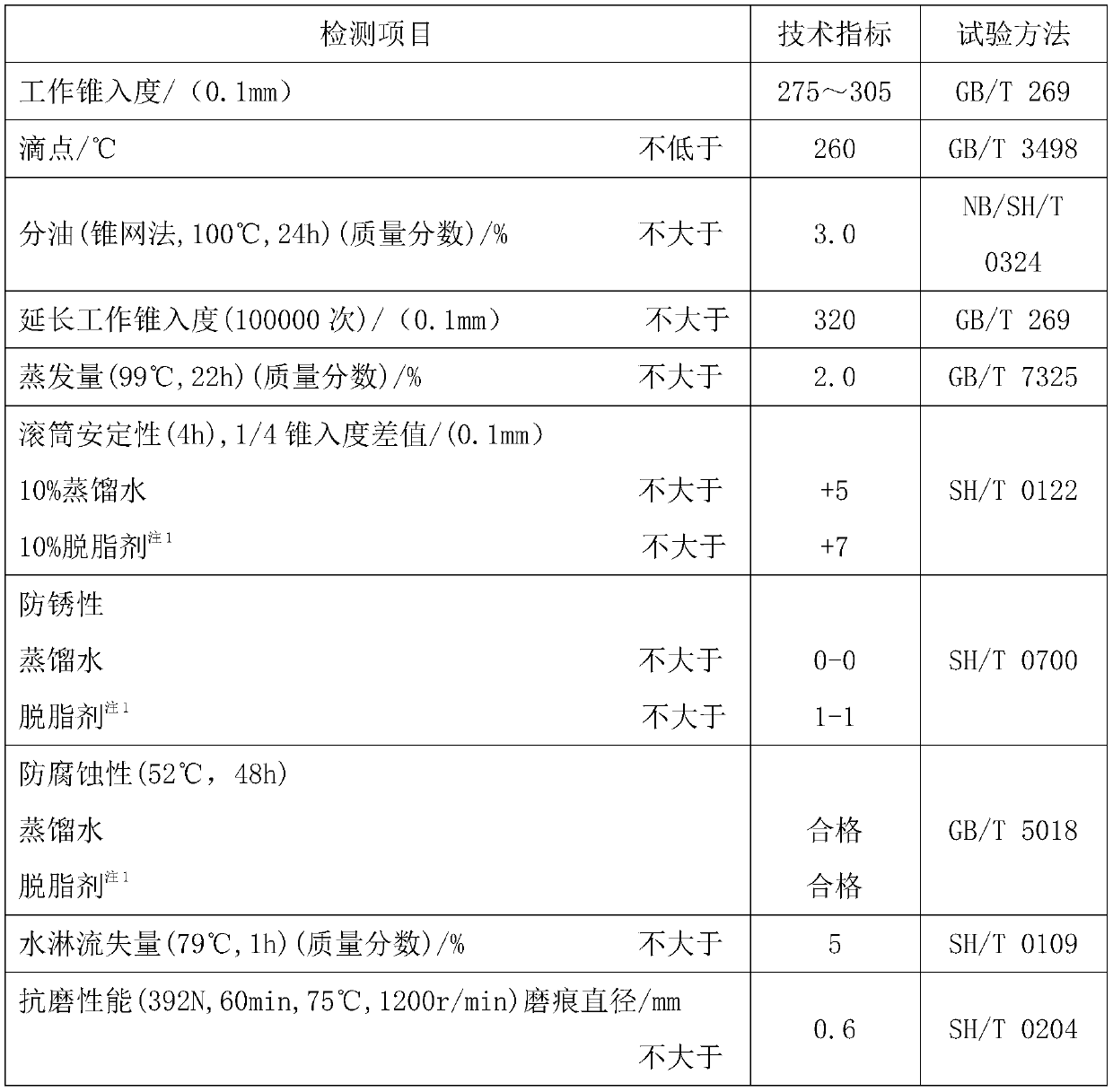

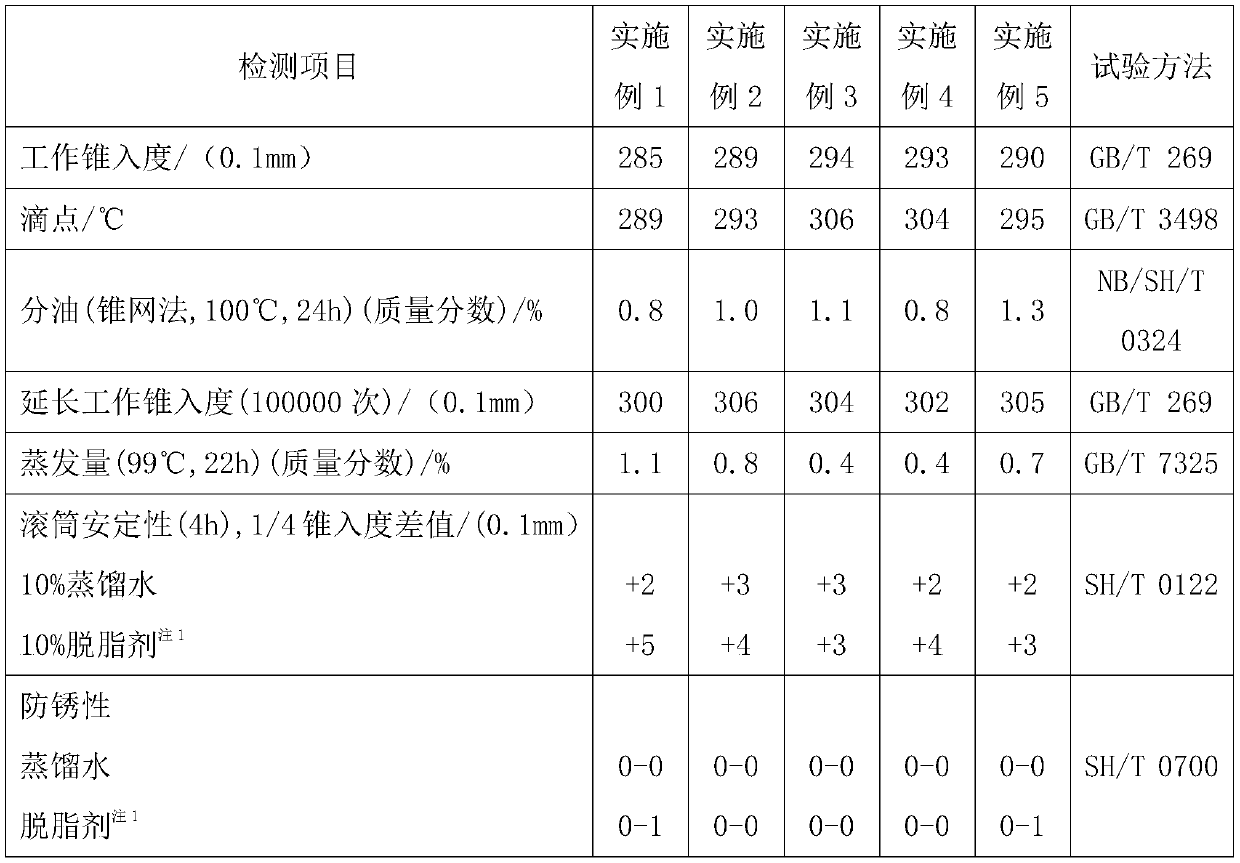

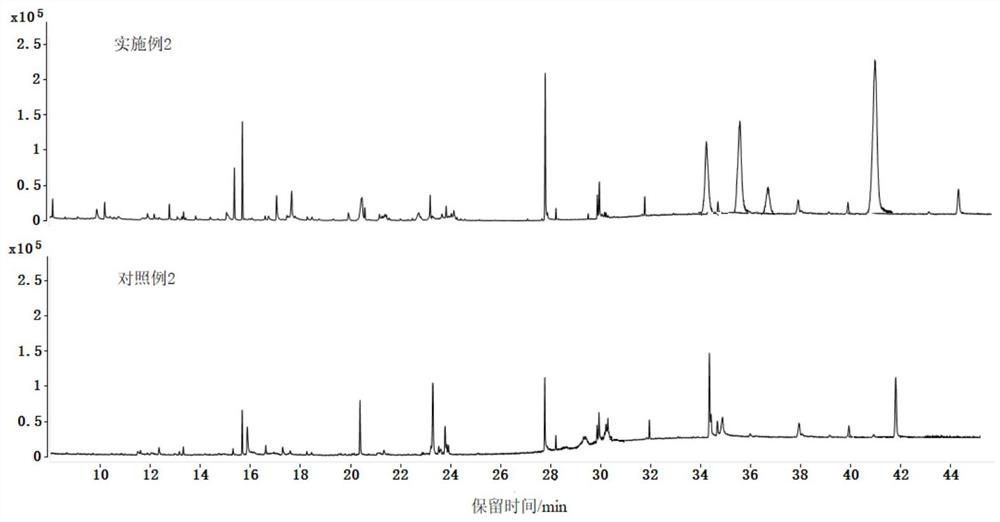

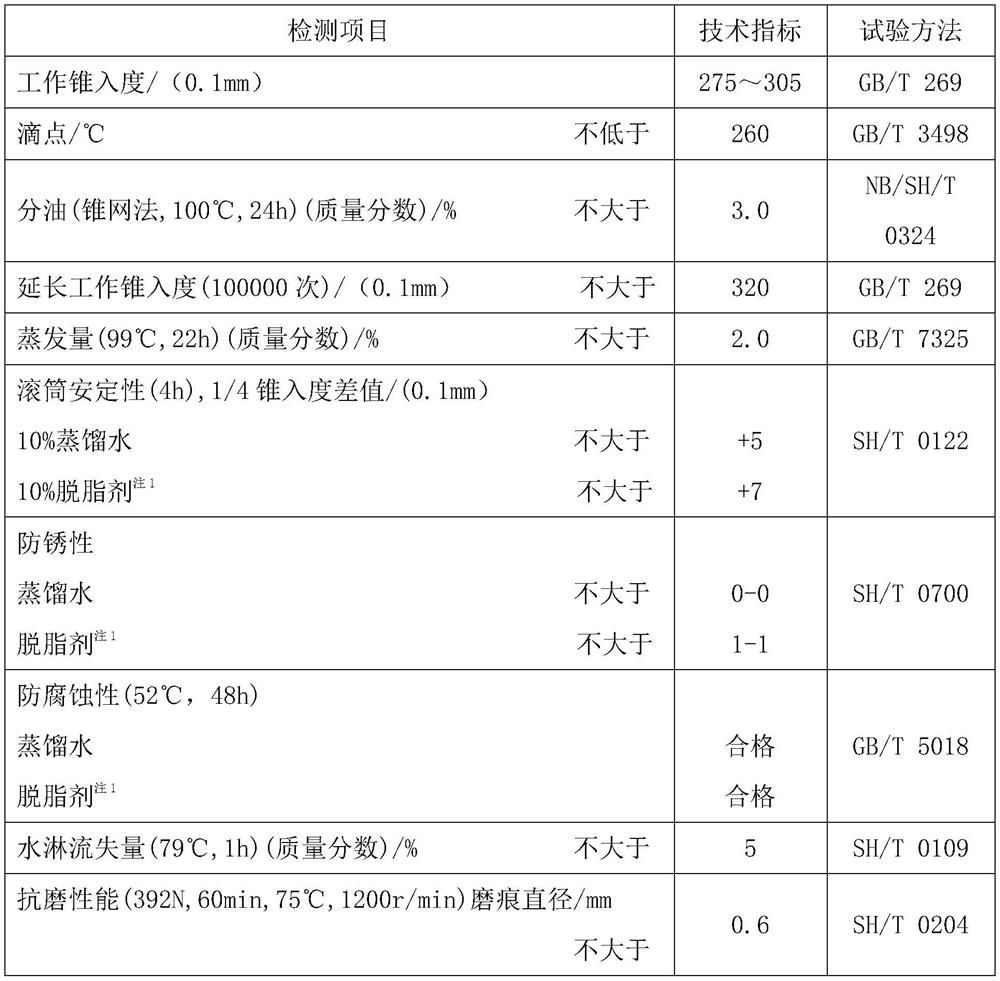

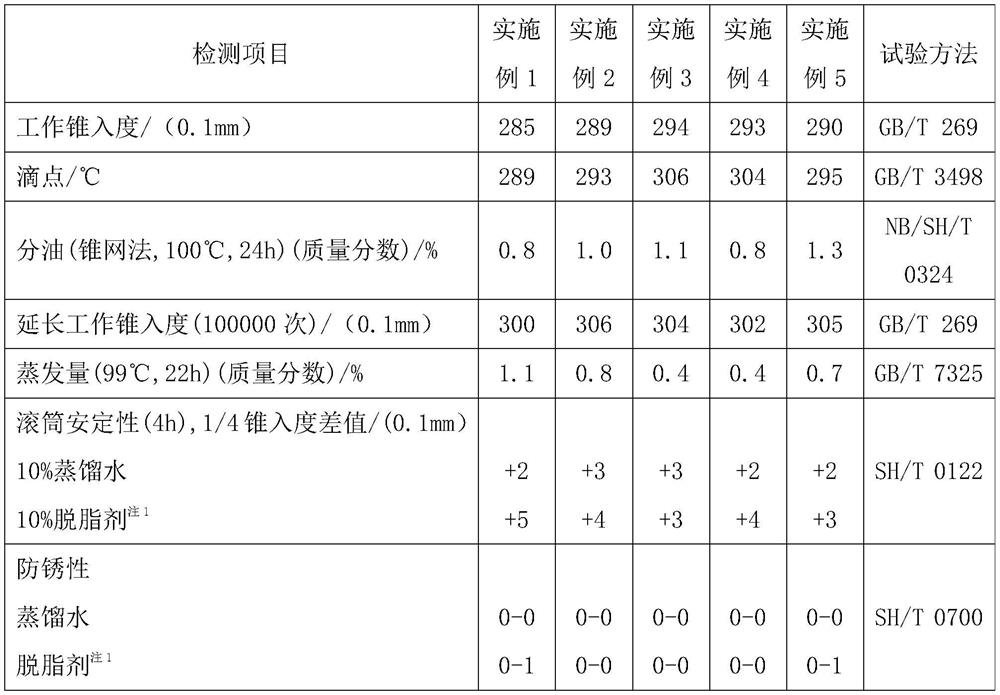

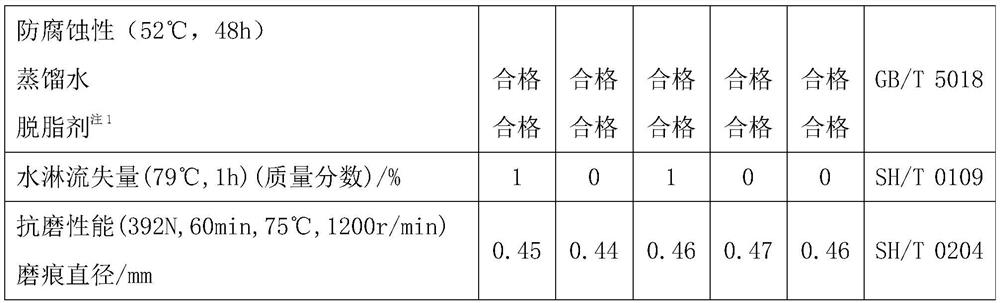

Alkaline-water-resistant lubricating grease and preparation method thereof

The invention relates to an alkaline-water-resistant lubricating grease, which comprises the following raw materials in parts by weight: 75.0-90.0 parts of base oil; 2.0 to 7.0 parts by weight of isocyanate; 2.2 to 7.5 parts by weight of organic amine; 0.2 to 1.0 part by weight of an antioxidant; 0.1 to 2.0 parts by weight of a tackifier; 0.3 to 2.0 parts by weight of an antirust agent; 0.1 to 5.0parts by weight of an emulsification inhibitor; 0.1 to 5.0 parts by weight of a coagulant; 0.3 to 1.5 parts by weight of an anti-wear agent; wherein the organic amine is aniline and cyclohexylamine,and the weight ratio of the aniline to the cyclohexylamine is 0.2-0.6. The basic grease of the alkaline-water-resistant lubricating grease is polyurea lubricating grease, and the polarity of the basicgrease is weaker than that of metallic soap, so that the soap fiber structure is not easily damaged by the influence of a strong-basicity degreasing agent; the alkaline-water-resistant lubricating grease can be used for preventing various degreasing agents such as an organic solvent, an alkaline agent and a surfactant from damaging lubrication.

Owner:辽宁海华科技股份有限公司

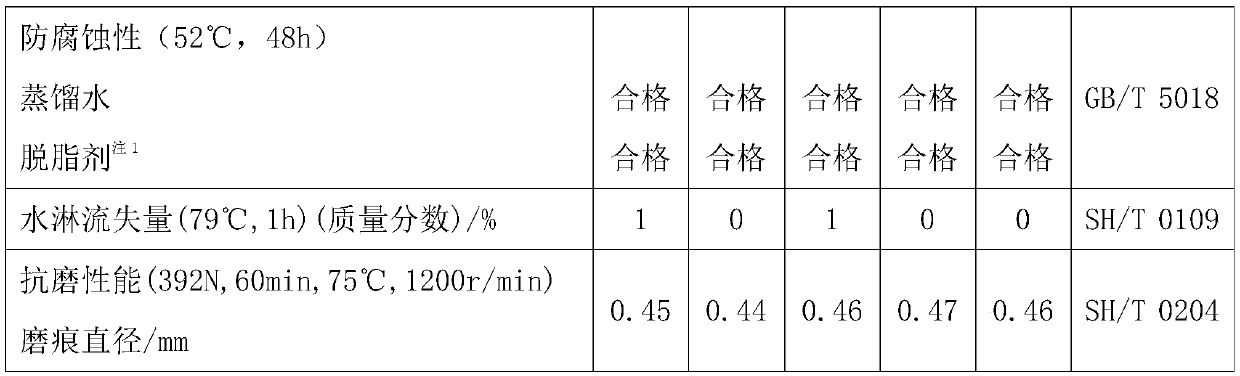

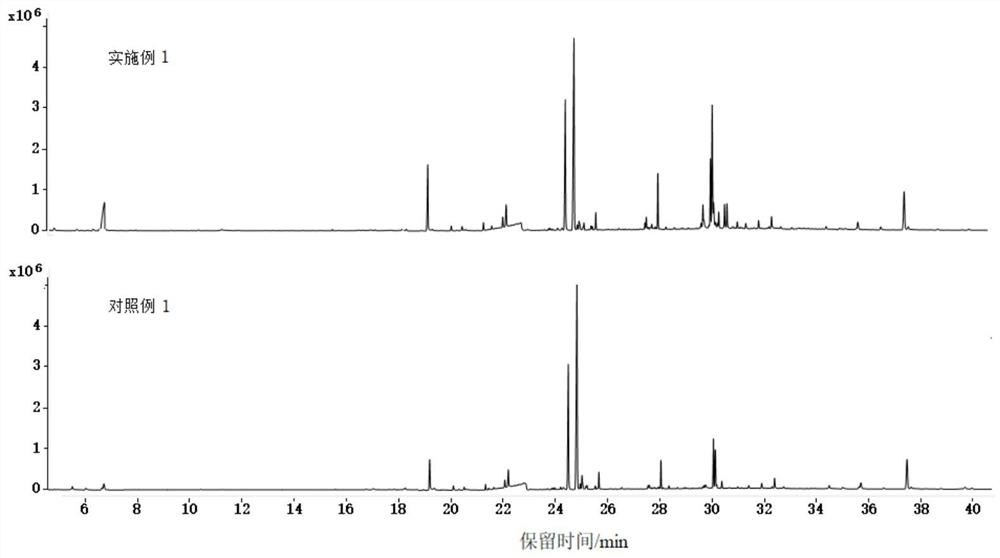

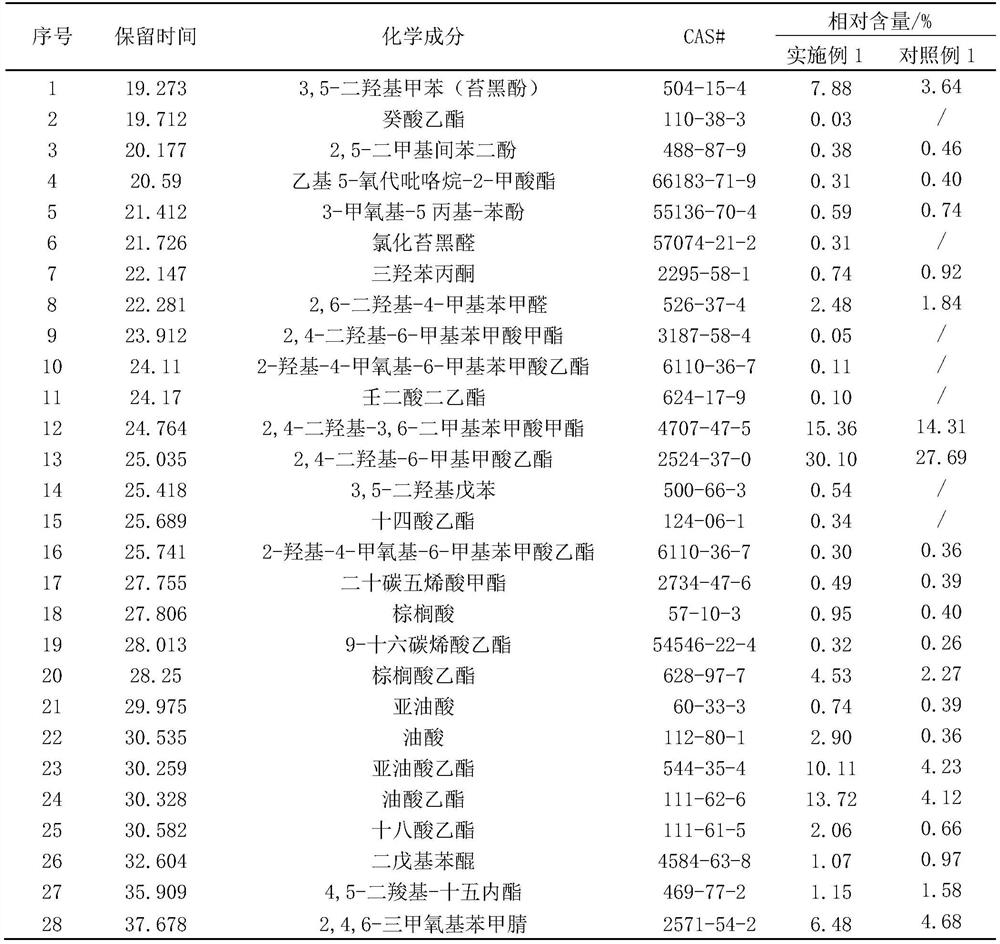

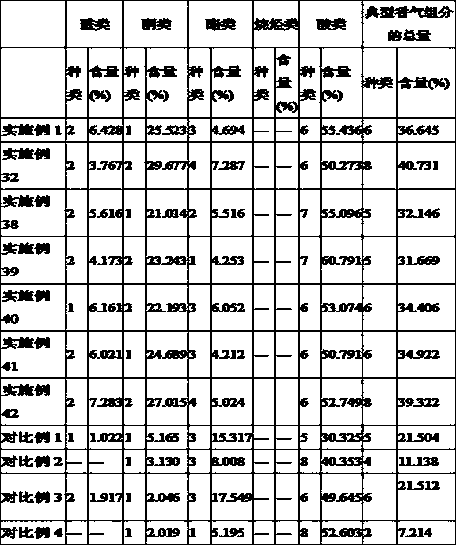

Tobacco flavor characteristic component analysis method and pretreatment method thereof

PendingCN114878285AReduce dosageIncrease freedomComponent separationPreparing sample for investigationOrganic solventSolvent

The invention relates to the technical field of analysis and detection of tobacco flavors, in particular to a tobacco flavor characteristic component analysis method and a pretreatment method thereof. The pretreatment method for characteristic component analysis of the tobacco flavor comprises the following steps: dissolving the tobacco flavor with a solvent to prepare a flavor diluent; carrying out adsorption treatment on the perfume diluent by adopting macroporous adsorption resin; carrying out supercritical elution on the macroporous adsorption resin subjected to adsorption treatment, and collecting eluent, so as to obtain the pretreated tobacco flavor liquid. According to the pretreatment method, the tobacco flavor is dissolved without being limited by a solvent and a material-liquid ratio; by utilizing the extraction and carrying capacities of fluid carbon dioxide extraction, the obtained aroma components are comprehensive, the enrichment efficiency is high, and the method is environment-friendly and non-toxic; the using amount of an eluent is small, the obtained eluent does not need to be concentrated, the loss of flavor components is effectively avoided, and the concentration of the flavor components is high; the use of a large amount of organic solvents is avoided, the method is environment-friendly, the extract liquor is free of impurities, and the pollution to instruments is reduced.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Preparation method for composite fireproof door core board

PendingCN110757823AHigh strengthImprove fire performanceFlat articlesActive agentSurface-active agents

The invention belongs to the technical field of building materials, in particular to a preparation method for a composite fireproof door core board. According to the preparation method, after being emulsified, liquid paraffin is mixed with emulsified acrylic acid, and thermoplastic resin, the modified emulsified liquid paraffin, magnesium-containing fiber pulp, diatomite matrix fireproof filling and desulfurated gypsum powder are mixed and preheated to finally obtain the composite fireproof door core board. The diatomite matrix fireproof filling fills in wood pulp fibers, so that the binding action of magnesium salt cement and the wood pulp fibers is enhanced, and the strength of the fireproof door core board is increased; a large amount of ammonium polyphosphate fills in diatomite pores in the diatomite matrix fireproof filling, so that the fireproof performance of the fireproof door core board is improved; the liquid paraffin is emulsified with a surface active agent, so that the damp-proof performance of the fireproof door core board is enhanced; taking resin glue as dipping glue, the fireproof door core board is not liable to erode by dampness; melamine does not contain carbon,so that the fireproof performance is high; and under the micro-pore absorption action of diatomite, the liquid paraffin cannot seep from the fireproof door core board, so that the fireproof door coreboard has lasting damp-proof performance, keeps the size stability of the fireproof door core board, and has a broad application prospect.

Owner:刘鹏

A kind of anti-alkali water lubricating grease and preparation method thereof

The invention relates to an anti-alkaline water lubricating grease. The composition of the raw materials is as follows: base oil: 75.0-90.0 parts by weight; isocyanate: 2.0-7.0 parts by weight; organic amine: 2.2-7.5 parts by weight; antioxidant: 0.2 ~1.0 parts by weight; tackifier: 0.1~2.0 parts by weight; antirust agent: 0.3~2.0 parts by weight; emulsification inhibitor: 0.1~5.0 parts by weight; coagulant: 0.1~5.0 parts by weight; ~1.5 parts by weight; the organic amine is aniline and cyclohexylamine, the weight ratio of which is 0.2~0.6. Anti-alkali water grease, its base grease is polyurea grease, because its polarity is weaker than that of metal soap, the soap fiber structure is not easily damaged by strong alkaline degreasing agents; anti-alkaline water grease can be used to protect organic solvents Various types of degreasing agents, such as alkaline agents and surfactants, can damage lubrication.

Owner:辽宁海华科技股份有限公司

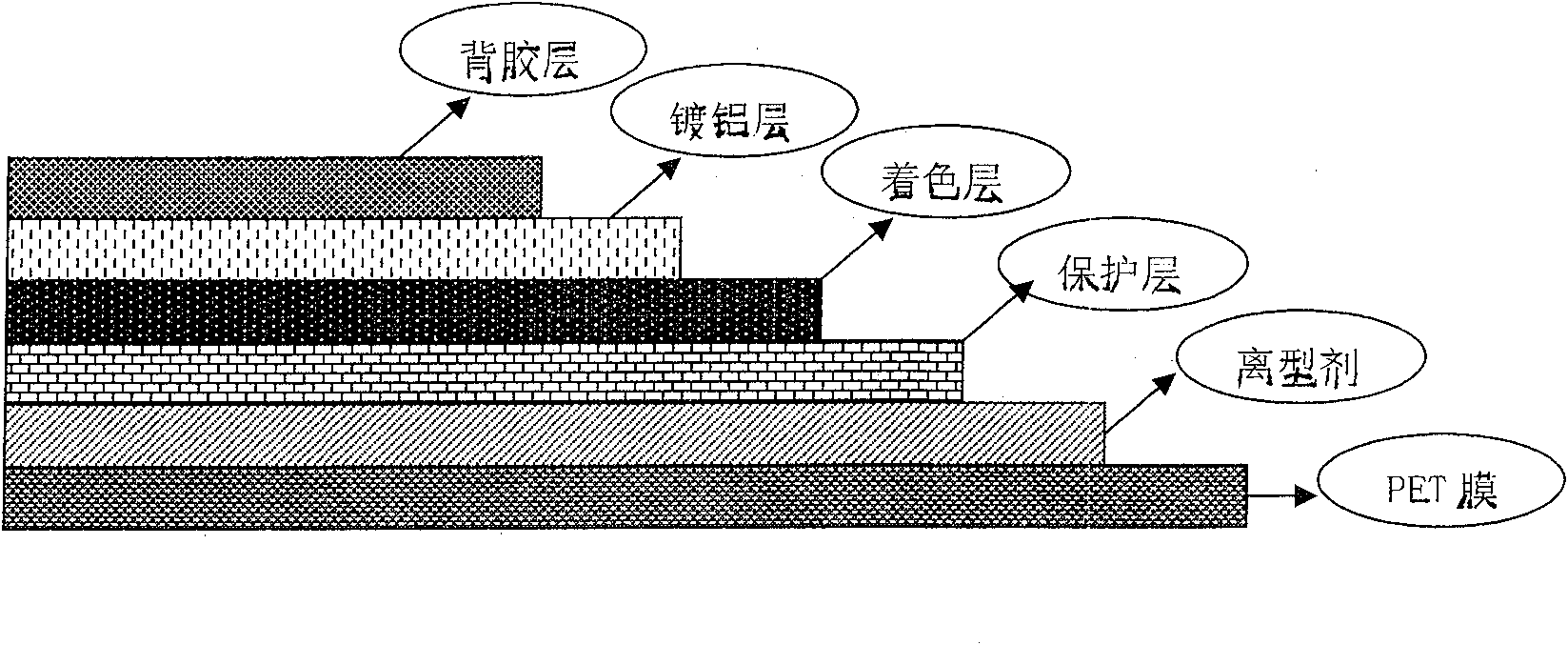

Hot printing adhesive for leather full wiped film and preparation method thereof

InactiveCN100567433CImprove adhesionGood softening and bonding performanceMineral oil hydrocarbon copolymer adhesivesDyeing processHot stampingOrganic solvent

The invention provides a hot stamping adhesive for leather full transfer film, which comprises: 10-30 polyester resin, 5-15 neoprene resin, 1-5 tackifying resin, and 2-10 inorganic filler in parts by weight , Organic mixed solvent 50-80. The back adhesive has excellent bonding performance to the aluminum layer of the full transfer film and the transfer carrier leather, paper, etc.; the hot stamping temperature is low, and the adhesive has good softening and bonding performance when the hot pressing temperature is 90°C; The polarity of the solvent used is relatively weak, only a small amount of ketone solvent is used, and there is basically no corrosion to the aluminum layer and the colored layer.

Owner:SHANXI UNIV

A kind of fat-soluble gardenia blue pigment and preparation method thereof

ActiveCN107973750BWeak polarityAvoid introducingCosmetic preparationsOrganic chemistryGenipinMedicinal chemistry

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

A comb-shaped polysiloxane and its solid electrolyte, preparation method and application

ActiveCN103421190BExcellent mechanical propertiesFacilitate dissociationSecondary cellsHydrogenLithium-ion battery

The invention discloses a comb polysilicone and solid electrolyte, a preparation method and application thereof. Through additive reaction of polymethyl hydrogen siloxane with olefinic hydrocarbon, an alkoxysilane group and a carbonic ester group are led onto a branch chain, and the comb polysilicone is prepared. The preparation method is simple and the cost is low; the solid electrolyte prepared by taking the comb polysilicone as main raw material is high in electric conductivity at a low temperature, the electric cycling performance of the prepared all solid lithium ion battery is excellent, and the select range and the application field of the solid electrolyte material are expanded.

Owner:王海斌

High-binding-power odor-removing water-based vacuum plastic emulsion and preparation method thereof

ActiveCN111286288AFacilitate addition reactionWeak polarityGraft polymer adhesivesPolymer sciencePropanoic acid

The invention relates to a high-adhesion odor-removing water-based vacuum plastic emulsion and a preparation method thereof. The main component of the high-adhesion odorless water-based vacuum plasticemulsion is an imidazolyl propionate modified polyurethane compound, imidazolyl propionate has strong surface affinity with low surface tension, the rigidity is large, cohesive energy is high, and high adhesion force can be provided; residual acrylate, imidazole and derivatives thereof are subjected to an addition reaction in the synthesis process; obtained odorless, odorless and non-volatile small molecules can be used as a wetting agent to be rapidly spread on the surface of a base material, meanwhile, one end of the small molecules serving as an interface agent closely acts on the base material, the other end of the small molecules is combined with a polymer containing an imidazole structure, and the adhesive force of the polymer on the surface of the base material is improved. The water-based vacuum plastic emulsion is solvent-free, odorless, high in binding power and simple and convenient in post-treatment.

Owner:福建华夏蓝新材料科技有限公司

A kind of preparation method of effective part of Yemachai

The invention discloses a preparation method for a lindley eupatorium effective part and belongs to the technical field of traditional Chinese medicines and natural medicines. The method comprises the following steps: extracting lindley eupatorium with water or hydrous ethanol and adopting macro-porous resin and supercritical fluid extraction technique for acquiring lindley eupatorium terpene lactones part. The preparation method for the lindley eupatorium terpene lactones effective part is simple, no toxic reagent is used, the production process is green, safe and quick and the preparation method is suitable for large-scale production.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

A kind of purposes of two-photon fluorescent probe

ActiveCN109946276BMolecular response time is shortHigh detection sensitivityOrganic chemistryFluorescence/phosphorescenceImage resolutionFluorescence

The present invention relates to the technical field of two-photon fluorescent probes, in particular, to the use of a two-photon fluorescent probe, which is used in cell and tissue imaging to detect lipid raft content and distribution dynamics. The probe can improve the accuracy, precision, sensitivity, and imaging resolution of lipid raft detection, and provide new ideas for further prevention and control of neurodegenerative diseases such as Alzheimer's disease and prion disease.

Owner:ZUNYI NORMAL COLLEGE

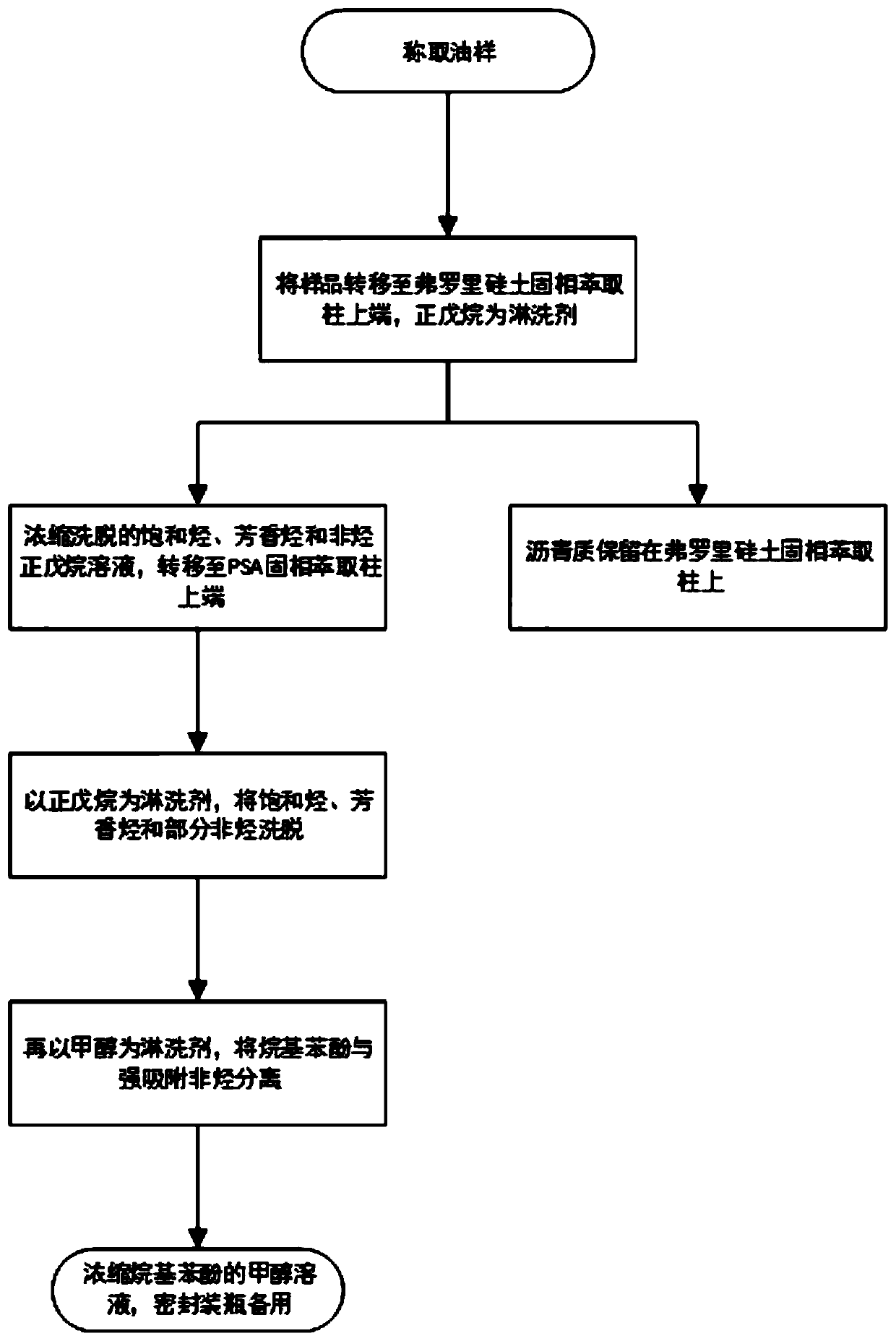

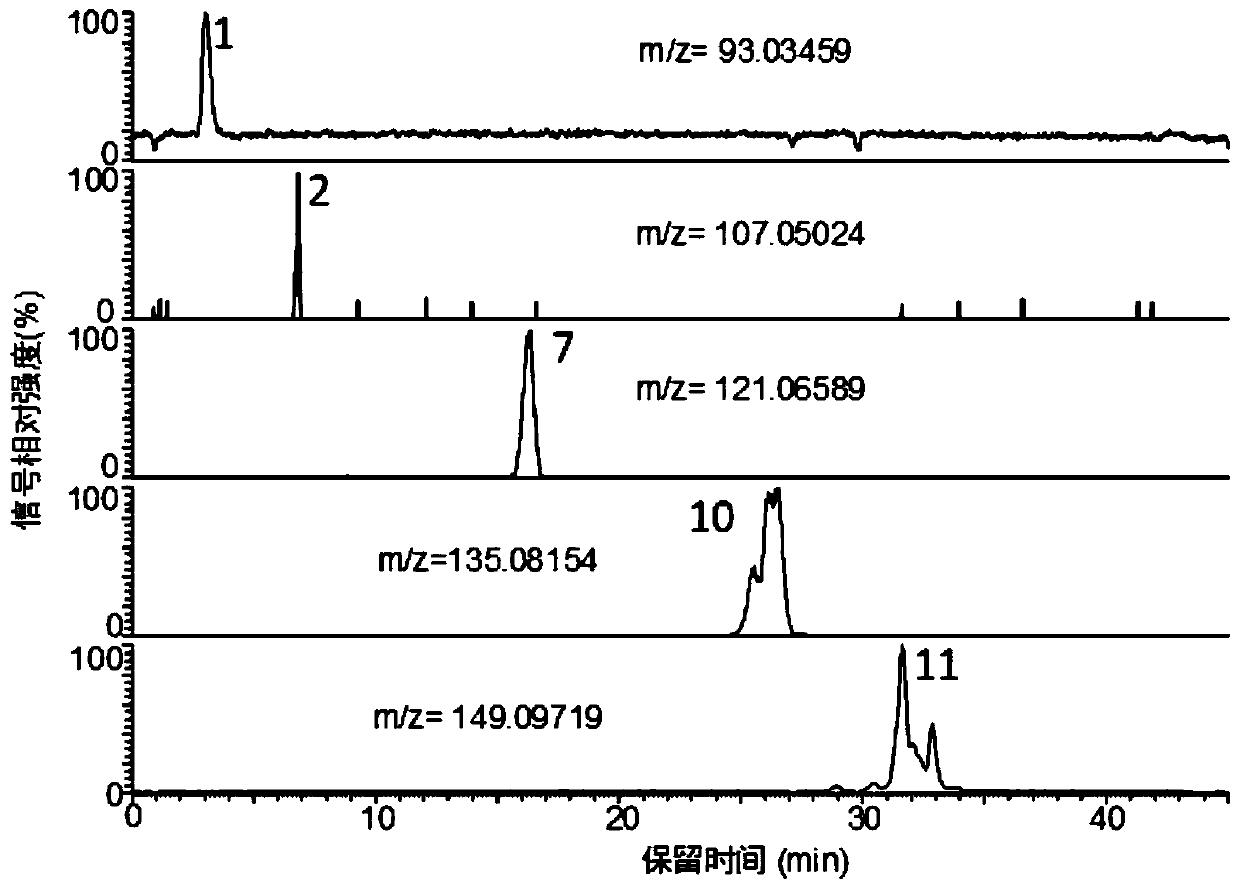

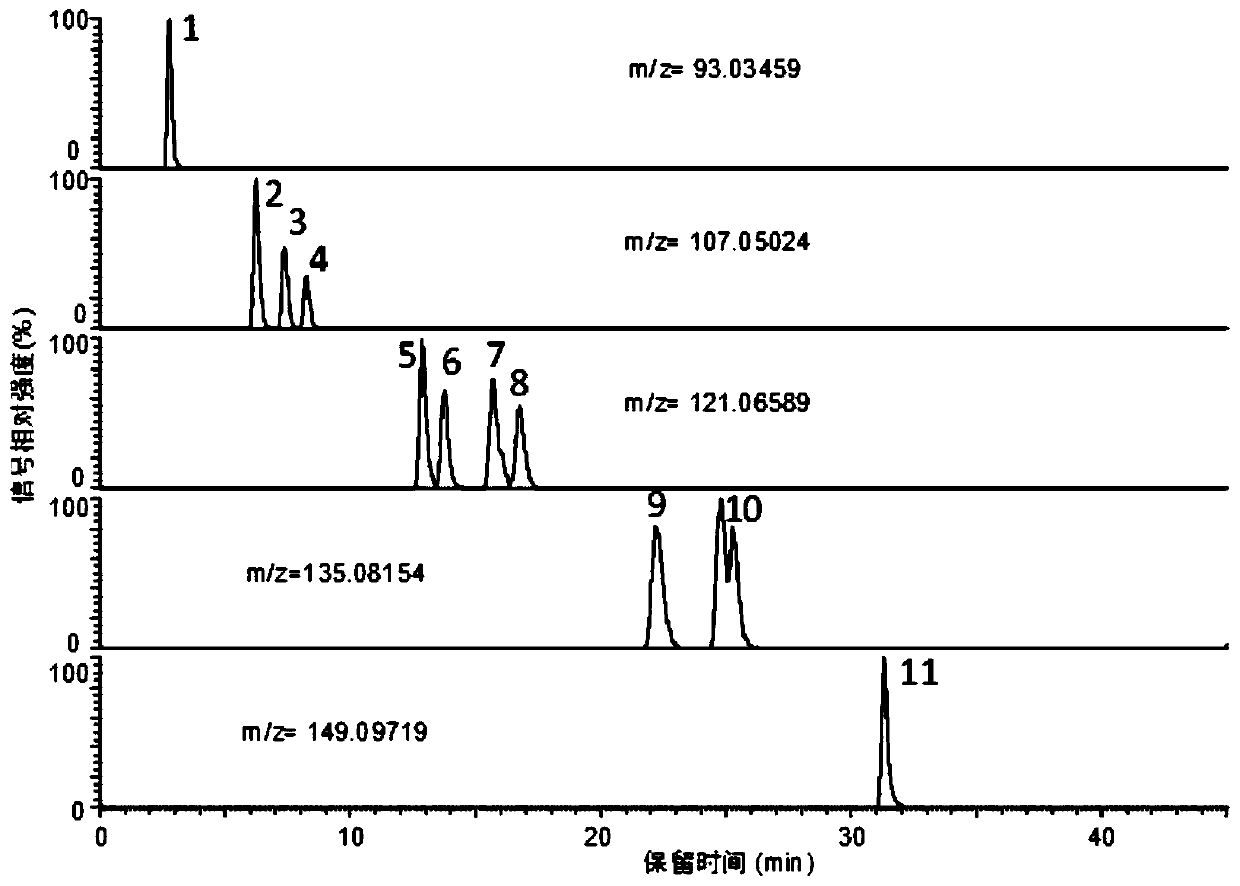

A kind of separation method of alkylphenol in crude oil

ActiveCN107670333BEasy to elutePromote enrichmentCation exchanger materialsComponent separationEthylenediamineSorbent

Owner:PETROCHINA CO LTD

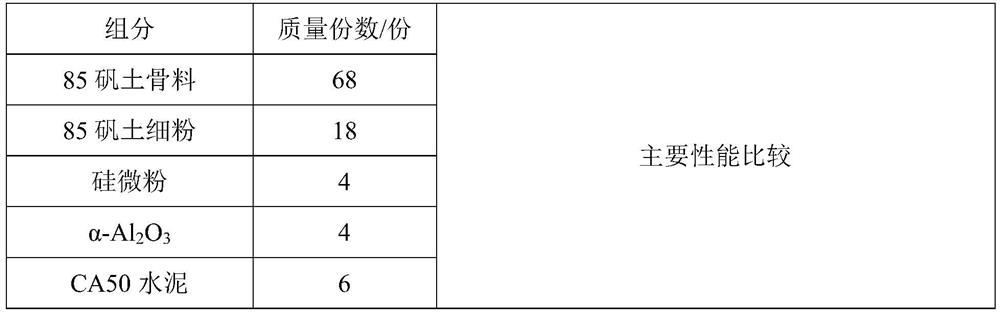

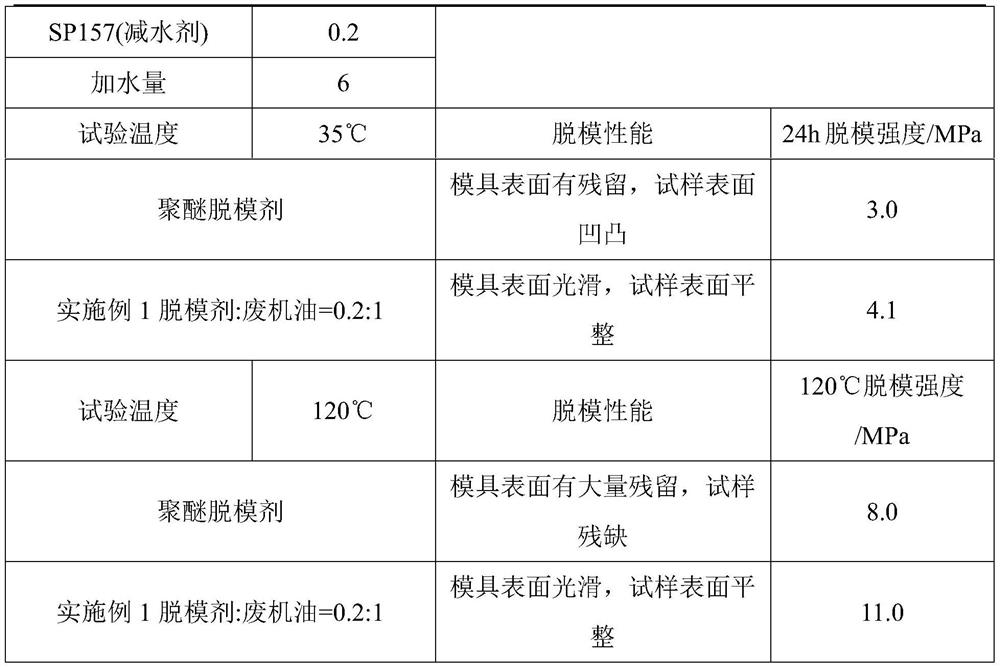

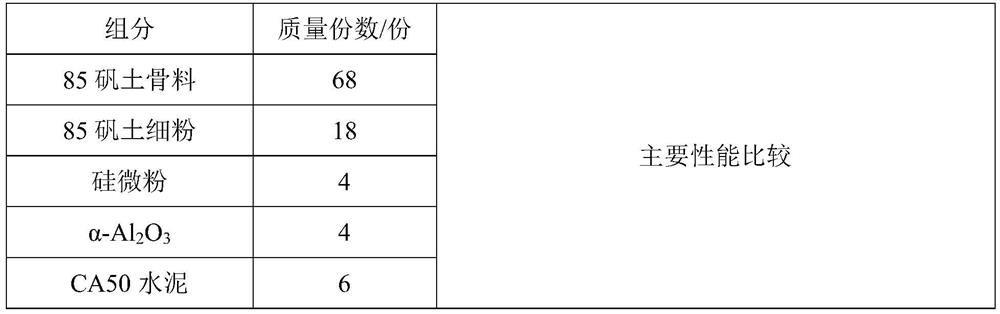

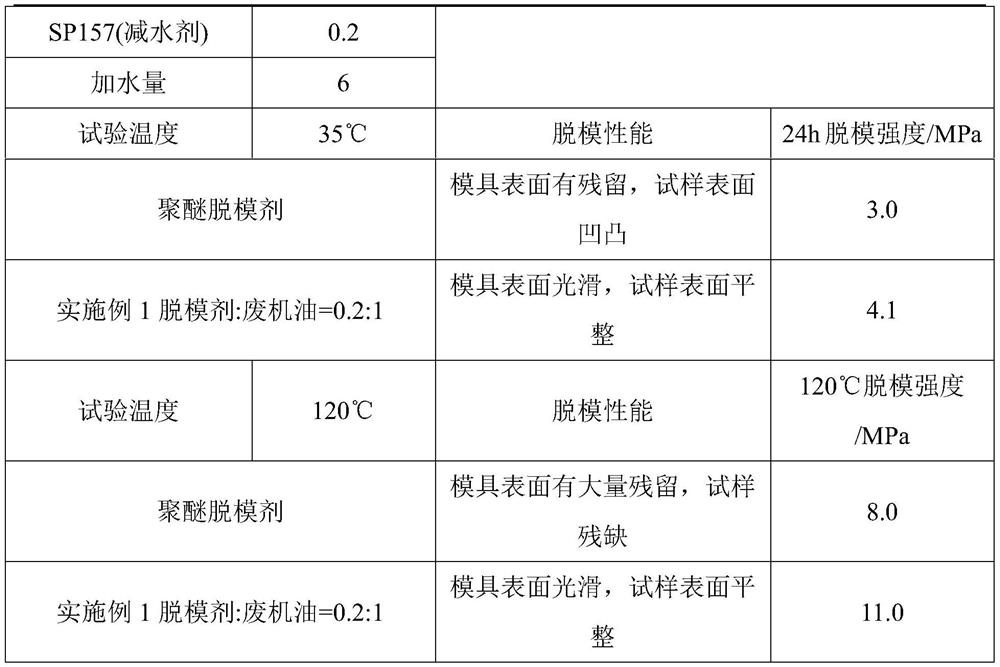

A kind of environment-friendly release agent for refractory materials and its preparation and use method

The invention provides an environmentally friendly release agent for refractory materials. The components and mass ratio of the release agent are: 80-150 parts of hydrogen-containing organosilicon monomer, 50-70 parts of polyether monomer, 2-5 parts of silphenyne monomer, 0.02-0.04 part of catalyst, 20-50 parts of plasticizer, 1-2 parts of coupling agent; the silphenyne monomer is n-dodecyltriphenylethynylsilane , n-octadecyltriphenylethynylsilane, n-tetradecyltriphenylethynylsilane, n-hexyltriphenylethynylsilane, or a mixture of two or more. The release agent has good temperature resistance, and is applicable to construction environments with relatively low temperatures in winter and relatively high temperatures in summer, and can also be applied to special environments such as high-temperature steam. Mixing environment-friendly mold release agent with waste engine oil can not only save resources, protect the environment, and reduce costs, but also has excellent mold release performance, smooth mold surface, and smooth sample surface.

Owner:武汉善达化工有限公司

Environment-friendly release agent for refractory material as well as preparation and use methods thereof

The invention provides an environment-friendly release agent for a refractory material. The release agent comprises the following components in parts by mass: 80-150 parts of a hydrogen-containing organic silicon monomer, 50-70 parts of a polyether monomer, 2-5 parts of a silicon benzyne monomer, 0.02-0.04 part of a catalyst, 20-50 parts of a plasticizer and 1-2 parts of a coupling agent. The silicon benzyne monomer is any one or a mixture of more than two of n-dodecyl triphenylethynyl silane, n-octadecyl triphenylethynyl silane, n-tetradecyl triphenylethynyl silane and n-hexyl triphenylethynyl silane. The release agent is good in temperature resistance, can be suitable for construction environments with low temperature in winter and high temperature in summer, and can also be suitable forspecial environments with high-temperature steam and the like. When the environment-friendly release agent is used, the environment-friendly release agent and waste engine oil are mixed for use, resources can be saved, the environment is protected, the cost is reduced, the release performance is excellent, the mold surface is smooth, and the sample has flat surface.

Owner:武汉善达化工有限公司

Preparation method of decorative plate

The invention belongs to the technical field of building material preparation, and particularly relates to a preparation method of a decorative plate. The preparation method comprises the following steps: emulsifying white mineral oil, mixing the emulsified white mineral oil with emulsified acrylic acid, mixing thermoplastic resin, modified emulsion, fiber pulp, flame-retardant filler and desulfurized gypsum powder, and preheating to finally obtain the composite decorative plate. The flame-retardant filler is filled into wood pulp fibers by a method of adding the flame-retardant filler into the pulp, and the main component of diatomite is silicon dioxide, so that the fireproof performance is improved; pores of the diatomite in the flame-retardant filler are filled with a large amount of ammonium polyphosphate, so that gas-phase combustion is inhibited, and the flame-retardant and fireproof performance of the decorative plate is improved; the surfactant emulsion is used, so that the moisture resistance of the decorative plate is enhanced; the decorative plate takes resin glue as impregnation, so that the fireproof performance is high; the decorative plate is directly decomposed andsublimated under a high-temperature condition, and a large amount of smoke is not generated during combustion; the main part of white mineral oil is of a straight-chain alkane structure, so that the waterproof performance is improved; the decorative plate has lasting moisture resistance and a wide application prospect.

Owner:和致倍

A kind of epoxy resin modified polyurethane waterproof coating and preparation method thereof

The invention discloses epoxy-resin-modified polyurethane waterproof paint and a preparation method thereof. The epoxy-resin-modified polyurethane waterproof paint comprises the following components according to the parts by weight: 80-100 parts of polyether glycol, 20-40 parts of isophorone diisocyanate, 30-50 parts of an epoxy resin, 2-6 parts of hydroxy-terminated poly-dimethylsiloxane, 0.04-0.2 parts of chloroplatinic acid, 0.6-1 part of a silane coupling agent, 2-6 parts of dimethylolpropionic acid, 15-25 parts of acetone, 4-10 parts of trimethylamine, 0.02-0.5 parts of dibutyltin dilaurate, 5-10 parts of water, and 30-60 parts of inorganic filler. The preparation method comprises the following steps: S1: modifying the epoxy resin; S2: under the protection of nitrogen in 65-75 DEG C,performing a nucleophilic addition reaction of the polyether glycol; S3: in 70 DEG C, copolymerizing reaction products in the steps S1 and S2 and the dimethylolpropionic acid; and S4: neutralizing andhomogenizing. The epoxy-resin-modified polyurethane waterproof paint is capable of using the mutual crosslinking modification of polydimethylsiloxane, the epoxy resin and polyurethane, synthesizing the advantages of three parties, and improving the structure stability and the mechanical property of a coating film. The produced polyurethane waterproof paint can be tightly adhered to a non-polar base plane, and excellent in waterproof anti-penetrability performance.

Owner:ANHUI LENCAQI BUILDING MATERIAL

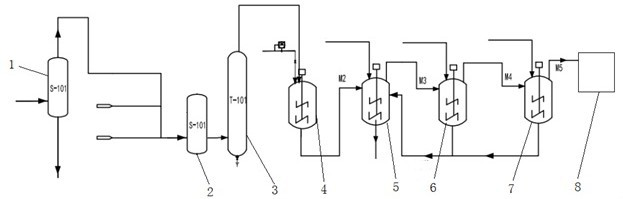

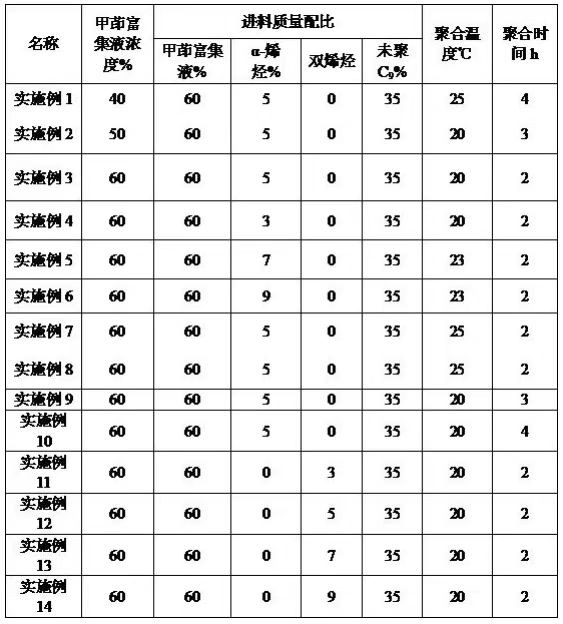

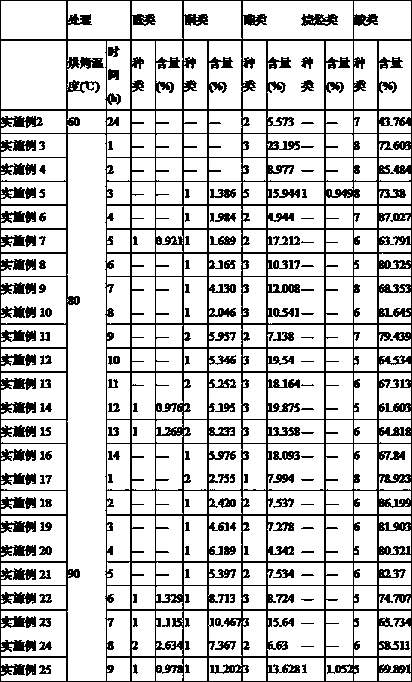

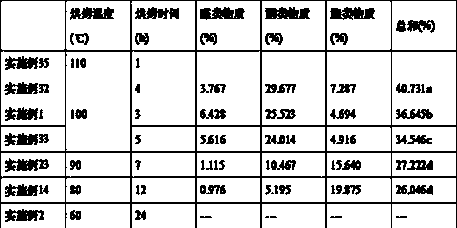

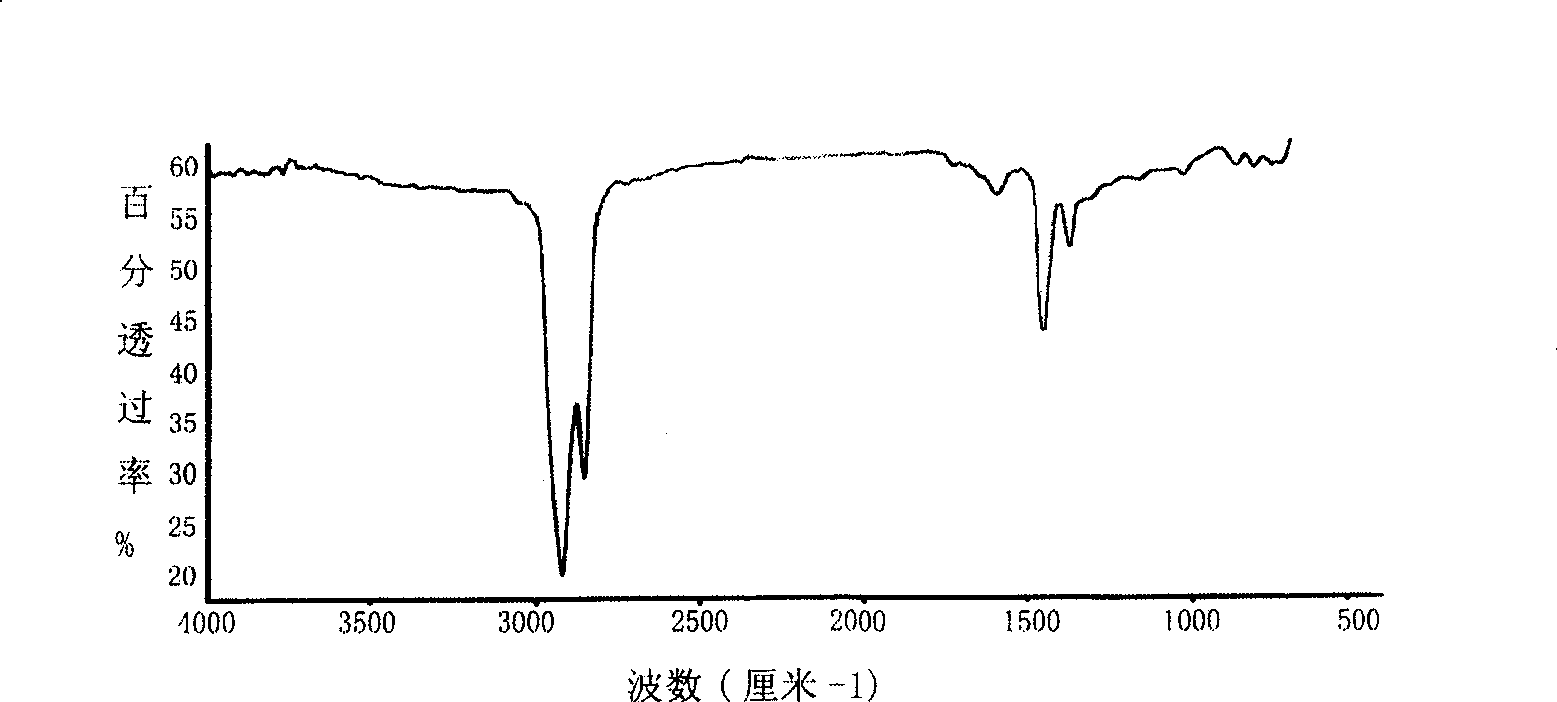

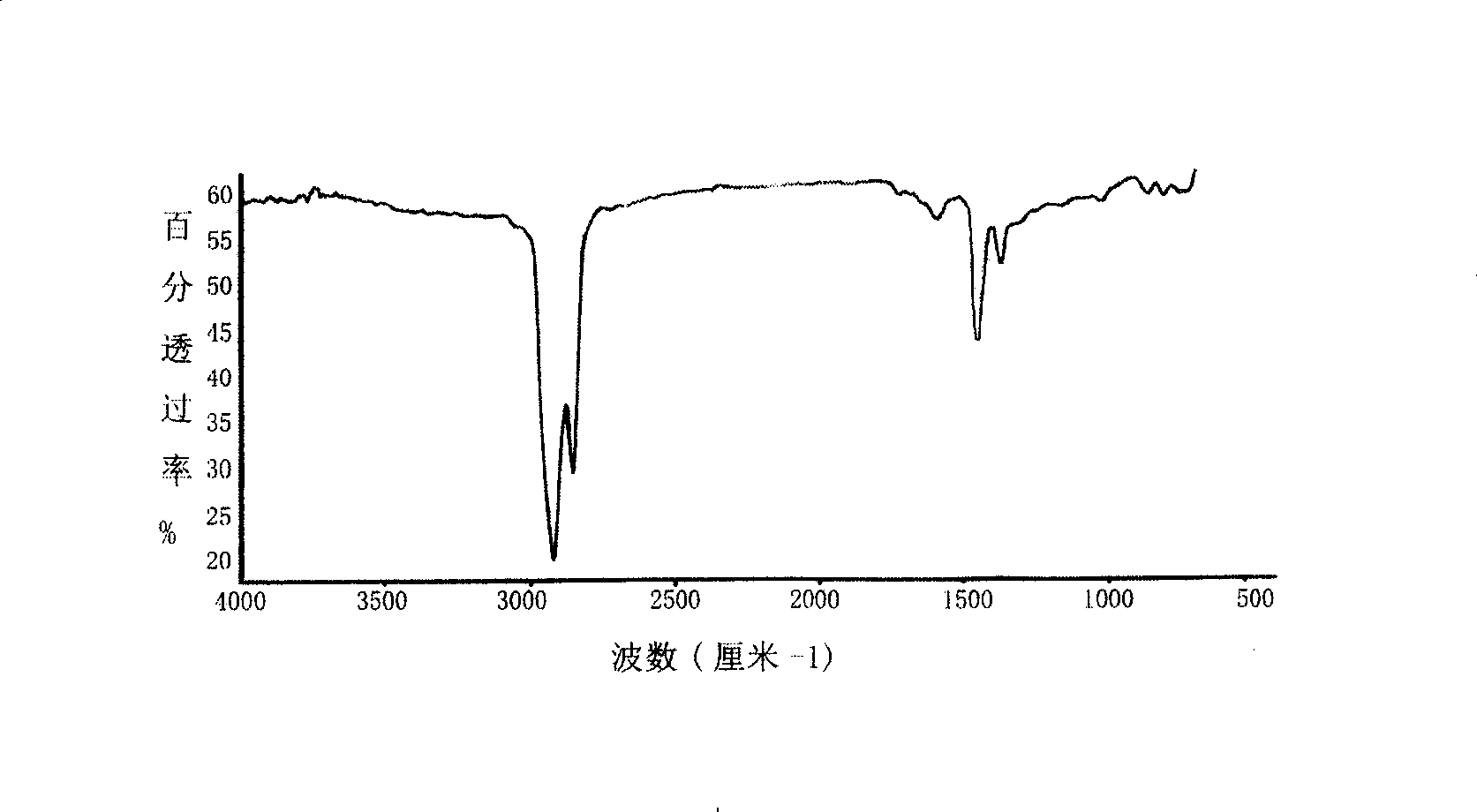

a change c 9 Preparation method of petroleum resin molecular polarity

ActiveCN111909314BWeak polaritySmall molecular weightMineral oil hydrocarbon copolymer adhesivesRolling resistance optimizationPolymer sciencePtru catalyst

The present invention relates to a change C 9 The preparation method of petroleum resin molecular polarity, methylindene enriched solution, α-olefin, unpolymerized C 9 Dehydrate after mixing, add BF 3 As a catalyst, a polymerization reaction occurs, the polymerization reaction temperature is 20-25°C, and the reaction time is 2-4h; after the polymerization reaction is completed, the catalyst BF is removed 3 ; Removal of the solvent gave C 9 petroleum resin. The present invention adopts α-olefin to change the structural polarity in the resin, and the obtained C 9 Petroleum resin, small molecular weight, light color, low wax fog point, weak polarity, good miscibility with EVA28 rubber.

Owner:FUSHUN QILONG CHEM

A kind of high-adhesion and deodorant water-based acrylate emulsion and preparation method thereof

Owner:福建华夏蓝新材料科技有限公司

A kind of processing technology of instant jujube powder

InactiveCN105380168BImprove solubilityEasily brokenFood thermal treatmentFood ingredientsSolubilitySoftened water

The invention belongs to the field of processing of Chinese date powder and in particular relates to a processing process of instant red date powder. The processing process comprises the following steps: (1) pre-treating; (2) enhancing aroma; (3) dissolving the aroma; (4) extracting; (5) removing ethanol; (6) drying. The processing process specifically comprises the following steps: selecting good red dates and cleanly washing; wiping and slicing; carrying out dry heat treatment on the red date slices to enhance the aroma; adding into a cold absolute ethanol solution while the red date slices are hot and stirring to dissolve the aroma; supplementing softened water and absolute ethanol, and then reflowing and extracting for two times; combining filtrates; after removing ethanol from the filtrate, adding a drying auxiliary agent and performing spraying drying to obtain the instant red date powder. The processing process has a simple process; the prepared instant red date powder has a high powder collection rate, good solubility, rich aroma and high content of nutrients and active components; less auxiliary materials are added so that the pure aroma, taste and color and luster of the red dates are kept.

Owner:HEBEI AGRICULTURAL UNIV.

Thermosetting epoxy asphalt material, preparation method and dedicated compatibilizer thereof

InactiveCN100460469CEasy to operateLow costWorking-up pitch/asphalt/bitumen by meltingBuilding insulationsEpoxyPolyol

The invention discloses a heat-solidity epoxy tar material, preparing method and specific dissolving-reinforcing agent, which comprises the following steps: allocating the raw material with 100% tar, 20-40% epoxy resin, 20-40% hardener and 20-60% heat-solidity epoxy tar; blending evenly; heating to 80-90 deg.c; stirring evenly; solidifying under 100-120 deg.c for 0.5-7h; obtaining the product. The invention provides a specific dissolving-reinforcing agent of heat-solidity epoxy tar material, which contains weak-polarity high-grade fat carbon chain and strong-polarity Mannish alkaline or compound of epoxy resin and polyol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com