Hot printing adhesive for leather full wiped film and preparation method thereof

A film transfer and hot ironing technology, applied in printing, dyeing, adhesives and other directions, can solve the problems of poor temperature resistance, color floating and smearing of the full transfer film, affecting the surface effect of the transfer skin, etc., to achieve excellent bonding performance, Good softening and bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

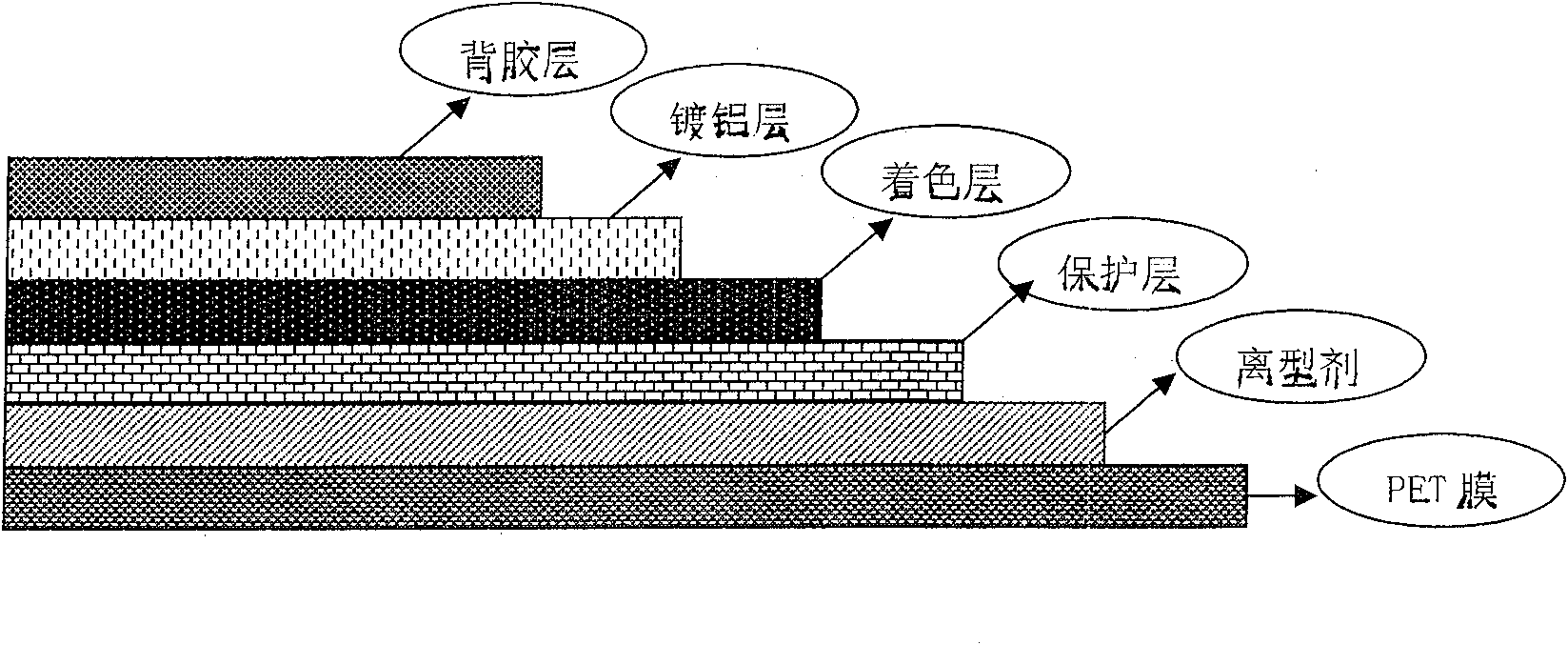

Image

Examples

Embodiment 1

[0026] Raw materials: polyester resin 189kg; neoprene resin 54kg; terpene tackifying resin 27kg; titanium dioxide 15kg; calcium carbonate 15kg; butanone 210kg; butyl acetate 280kg; toluene 210kg.

[0027] preparation:

[0028] (1) Add 210kg butanone and 280kg butyl acetate in the reactor, stir, and heat up to 60°C;

[0029] (2) Add 189kg of polyester resin, 54kg of neoprene resin and 27kg of tackifying resin successively, keep warm at 60°C and stir for two hours until the resin is completely dissolved;

[0030] (3) Then add 15kg titanium dioxide and 15kg calcium carbonate, stir until uniformly dispersed;

[0031] (4) Finally, add 210kg of toluene solution and stir evenly to prepare a hot stamping back glue for leather full transfer film with a solid content of 30%.

Embodiment 2

[0033] Raw materials: polyester resin 297.5kg; neoprene resin 85kg; terpene tackifying resin 42.5kg; titanium dioxide 50kg; calcium carbonate 25kg; butanone 150kg; butyl acetate 200kg; toluene 150kg.

[0034] preparation:

[0035] (1) Add 150kg butanone and 200kg butyl acetate in the reactor, stir, and heat up to 60°C;

[0036] (2) Add 297.5kg of polyester resin, 85kg of neoprene resin and 42.5kg of tackifying resin in turn, and keep warm at 60°C and stir for two hours until the resin is completely dissolved;

[0037] (3) Then add 50kg titanium dioxide and 25kg calcium carbonate, stir until uniformly dispersed;

[0038] (4) Finally, add 150kg of toluene solution and stir evenly to prepare a hot-stamping adhesive for leather full-transfer film with a solid content of 50%.

Embodiment 3

[0040] Raw materials: polyester resin 152kg; neoprene resin 87kg; terpene tackifying resin 31kg; titanium dioxide 18kg; calcium carbonate 12kg; butanone 210kg; butyl acetate 280kg; toluene 210kg.

[0041] preparation:

[0042] (1) Add 210kg butanone and 280kg butyl acetate in the reactor, stir, and heat up to 60°C;

[0043] (2) Add 152kg of polyester resin, 87kg of neoprene resin and 31kg of tackifying resin in turn, and keep warm at 60°C and stir for two hours until the resin is completely dissolved;

[0044] (3) Then add 18kg titanium dioxide and 12kg calcium carbonate, stir until uniformly dispersed;

[0045] (4) Finally, add 210kg of toluene solution and stir evenly to prepare a hot stamping back glue for leather full transfer film with a solid content of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com