Environment-friendly release agent for refractory material as well as preparation and use methods thereof

A technology of refractory materials and release agents, which is applied in the field of refractory materials, can solve the problems that the protective interface of the release agent is easily damaged, the release agent fails, and the temperature resistance of the release agent cannot meet the requirements, so as to achieve good emulsification and releasability, avoiding waste, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

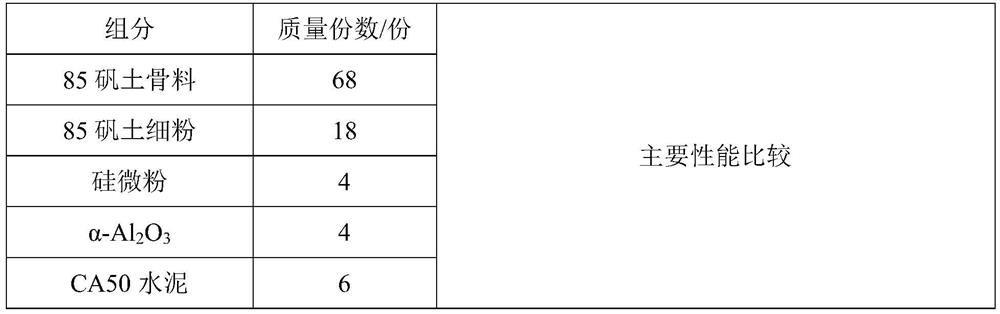

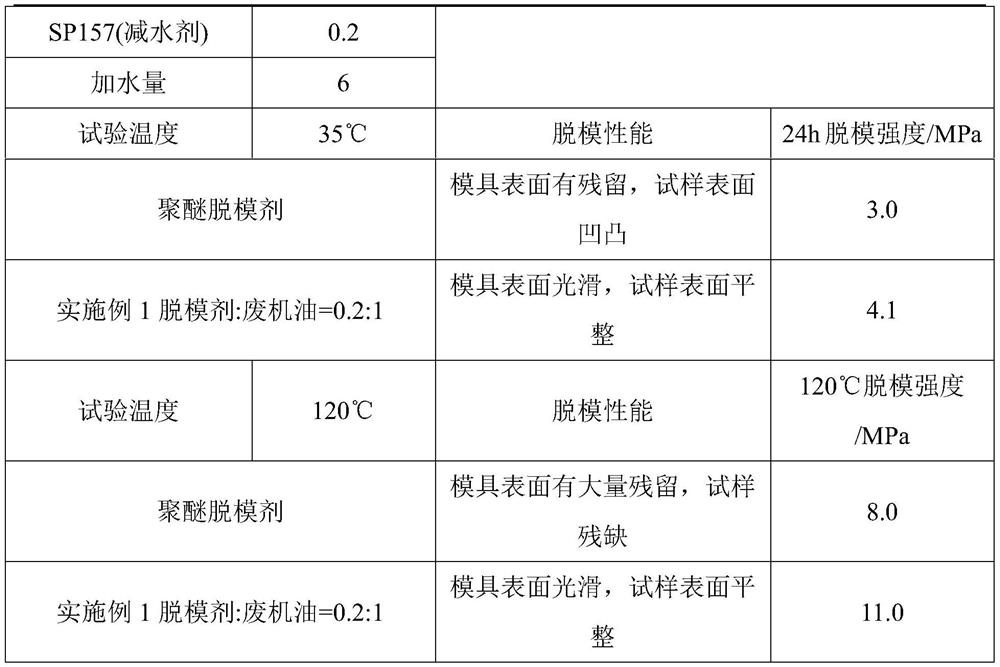

[0020] The environmentally friendly release agent for refractory materials provided in this example is prepared by the following method:

[0021] 150 parts of hydrogen-containing silicone monomer (1% hydrogen content, hydrogen-containing silicone oil with a viscosity of 0.3 Pa·s), 50 parts of polyether monomer (hydroxyl-terminated polyether with molecular weight between 2000 and 10000), plasticized Add 20 parts of agent (tri-n-butyl citrate and epoxidized soybean oil with molecular weight between 200 and 1000 1:10) into the reaction kettle, raise the temperature to 100°C, start stirring, set the stirring rate to 35r / min, and stir for 15min Finally, add 0.02 part of catalyst (chloroplatinic acid) and stir for 45 minutes, raise the temperature to 150°C, then add 2 parts of siliphenyne monomer (n-dodecyltriphenylethynylsilane) and keep it for 5h, cool down to 50°C, add 1 part of coupling agent and keep it out for 10 minutes to get an environmentally friendly release agent.

[00...

Embodiment 2

[0029] The environmentally friendly release agent for refractory materials provided in this example is prepared by the following method:

[0030] Mix 150 parts of hydrogen-containing silicone monomer (hydrogen-containing silicone oil with a hydrogen content of 1.2% and a viscosity of 0.4 Pa·s), 50 parts of polyether monomer (hydroxyl-terminated polyether with molecular weight between 2000 and 10000), plasticize Add 50 parts of agent (tri-n-butyl citrate and epoxidized soybean oil with a molecular weight between 200 and 1000 10:1) into the reaction kettle, heat up to 100°C, start stirring, set the stirring rate to 30r / min, and stir for 20min Finally, add 0.02 parts of catalyst (Castel catalyst) and stir for 45 minutes, heat up to 150°C, then add 5 parts of siliphenyne monomer (n-octadecyltriphenylethynylsilane) and keep it warm for 5h, then cool down to 50°C. Add 2 parts of coupling agent and keep discharging for 15 minutes to obtain an environmentally friendly release agent. ...

Embodiment 3

[0038] The environmentally friendly release agent for refractory materials provided in this example is prepared by the following method:

[0039] 100 parts of hydrogen-containing silicone monomer (hydrogen-containing silicone oil with hydrogen content of 0.8%, viscosity of 0.35 Pa·s), 55 parts of polyether monomer (hydroxyl-terminated polyether with molecular weight between 2000 and 10000), plasticizer (Tri-n-butyl citrate and epoxidized soybean oil with a molecular weight between 200 and 1000 1:1) 25 parts were added to the reaction kettle, the temperature was raised to 100°C, and the stirring was started, and the stirring rate was set at 30r / min. After stirring for 25 minutes, , add 0.03 parts of catalyst (selenocrown ether platinum complex) and stir for 45 minutes, heat up to 150 ° C, then add 3 parts of siliphenyne monomer (n-hexyltriphenylethynyl silane) and keep warm for 5 hours, cool down to 50 ° C, add 1.5 parts of coupling agent and kept for 15 minutes to discharge, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com