a change c 9 Preparation method of petroleum resin molecular polarity

A petroleum resin and molecular technology, which is applied in the field of preparation of changing the molecular polarity of C9 petroleum resin, can solve the problems of poor rubber compatibility, low activation energy of diolefins, and large resin polarity, and achieves weak polarity, waxy wax, etc. The effect of low fog point and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

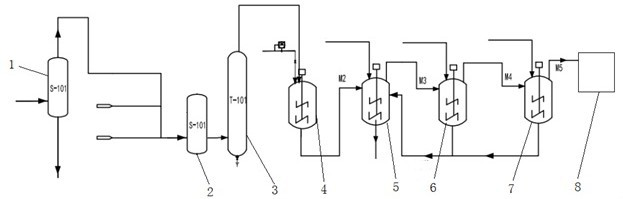

Image

Examples

Embodiment Construction

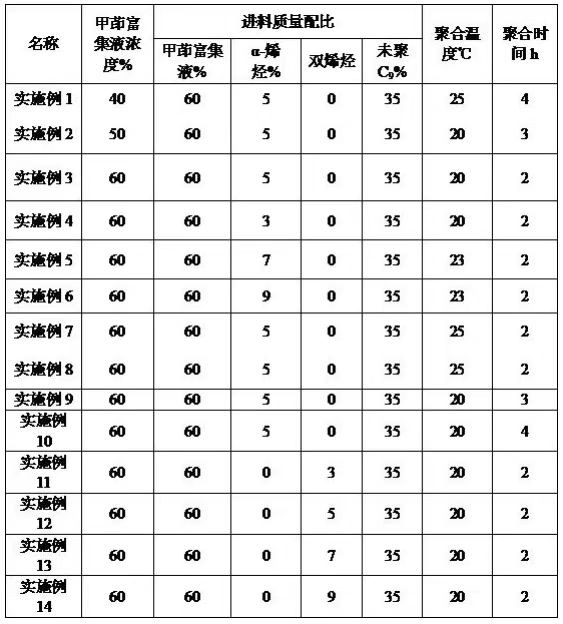

[0022] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0023] a change C 9 The preparation method of petroleum resin molecular polarity is carried out according to the following steps:

[0024] (1) Separating the methylindene enriched liquid from ethylene tar;

[0025] (2) Formindene enriched solution, α-olefin, unpolymerized C 9 Dehydrate after mixing, add BF 3 As a catalyst, a polymerization reaction occurs, the polymerization reaction temperature is 20-25°C, and the reaction time is 2-4h;

[0026] (3) After the polymerization reaction is over, remove the catalyst BF 3 ;

[0027] (4) Removal of the solvent gives C 9 petroleum resin.

[0028] Among them, methylindene enriched solution, α-olefin, unpolymerized C 9 The mass ratio is 60:(3~9):...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com