Preparation method of decorative plate

A decorative board and board technology, which is applied in the field of preparation of decorative boards, can solve the problems of easy moisture absorption and mildew in the bathroom, general flame retardant performance, and worrying safety, and achieve the goal of improving fire resistance, flame retardancy and fire resistance, and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

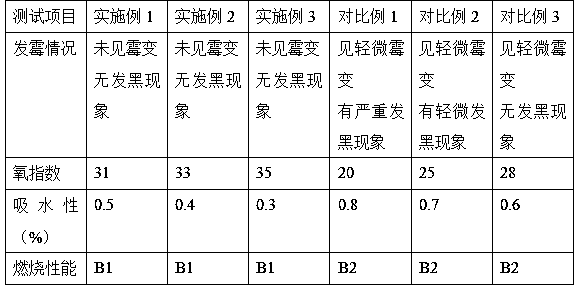

Examples

Embodiment 1

[0036] The surfactant is: alkylphenol polyoxyethylene ether

[0037] The thermoplastic resin is: PPE resin

[0038] Preparation of mixed products:

[0039] Take 60mL of phosphoric acid solution with a concentration of 0.4mol / L and pour it into a three-necked flask with an air duct. After heating the oil bath to 70°C, add urea into the three-necked flask, and control the molar ratio of phosphoric acid to urea to be 1:2. Continue to raise the temperature to 130°C at a heating rate of 2°C / min, add 10 g of diatomaceous earth into the three-necked flask, and keep it warm for 20 minutes to obtain a mixed product;

[0040] Preparation of fiber pulp:

[0041] The above mixed product was poured into a tray and transferred to an oven with a set temperature of 150°C, cured and dried for 2 hours, then placed in a mortar and ground for 30 minutes to obtain a flame-retardant filler, kraft softwood pulp with a solid content of 35%, Magnesium oxide powder, aluminum oxide powder, and ammoni...

Embodiment 2

[0049] The surfactant is: nonylphenol polyoxyethylene ether

[0050] The thermoplastic resin is: PI resin

[0051] Preparation of mixed products:

[0052] Take 62.5mL of phosphoric acid solution with a concentration of 0.4mol / L and pour it into a three-necked flask with an air duct, heat it in an oil bath to 75°C, then add urea into the three-necked flask, and control the molar ratio of phosphoric acid to urea to be 1:2 , continue to raise the temperature to 132.5°C at a heating rate of 2.5°C / min, add 11g of diatomaceous earth into the three-necked flask, and heat it for 25min to obtain a mixed product;

[0053] Preparation of fiber pulp:

[0054] Pour the above mixed product into a tray and transfer it to an oven with a set temperature of 175°C, solidify and dry for 2.5 hours, and then place it in a mortar and grind for 32.5 minutes to obtain a flame-retardant filler. The sulfate coniferous wood with a solid content of 35% pulp, magnesium oxide powder, aluminum oxide powde...

Embodiment 3

[0062] The surfactant is: octylphenol polyoxyethylene ether

[0063] The thermoplastic resin is: PEEK resin

[0064] Preparation of mixed products:

[0065] Take 65mL of phosphoric acid solution with a concentration of 0.4mol / L and pour it into a three-necked flask with an air duct. After heating the oil bath to 80°C, add urea into the three-necked flask, and control the molar ratio of phosphoric acid to urea to be 1:2. Continue to raise the temperature to 135°C at a heating rate of 3°C / min, add 12g of diatomaceous earth into the three-necked flask, and keep it warm for 30min to obtain a mixed product;

[0066] Preparation of fiber pulp:

[0067] The above mixed product was poured into a tray and transferred to an oven with a set temperature of 200°C, cured and dried for 3 hours, then placed in a mortar and ground for 35 minutes to obtain a flame retardant filler, kraft softwood pulp with a solid content of 35%, Magnesium oxide powder, aluminum oxide powder, and ammonia wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com