A comb-shaped polysiloxane and its solid electrolyte, preparation method and application

A technology of solid electrolyte and polysiloxane, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve problems such as poor electrical conductivity, and achieve the effects of improving mechanical properties, promoting dissociation, and strong exercise ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

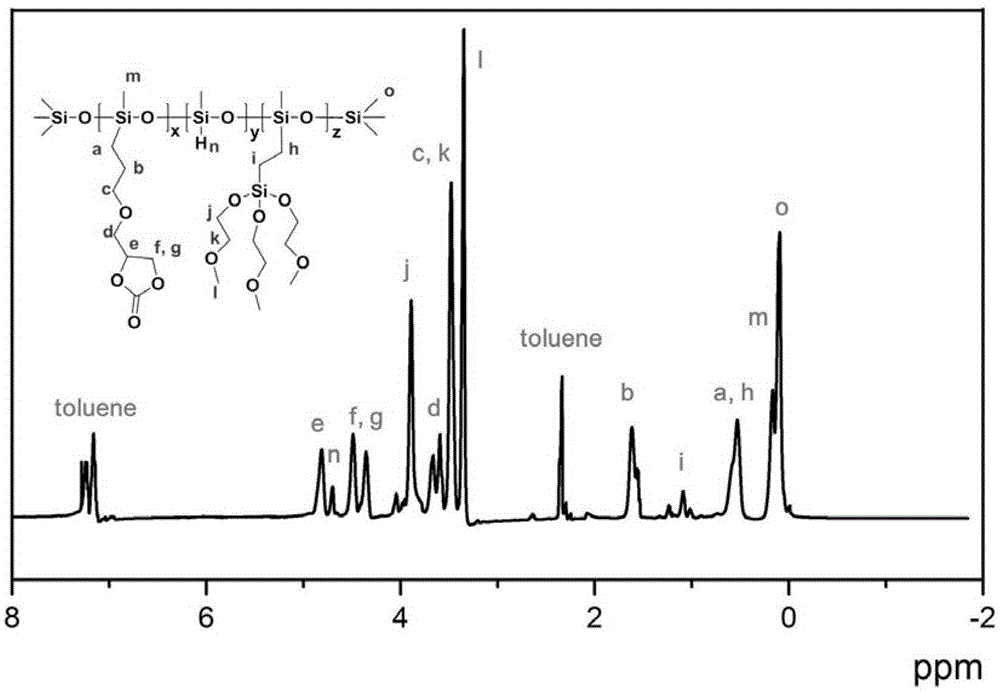

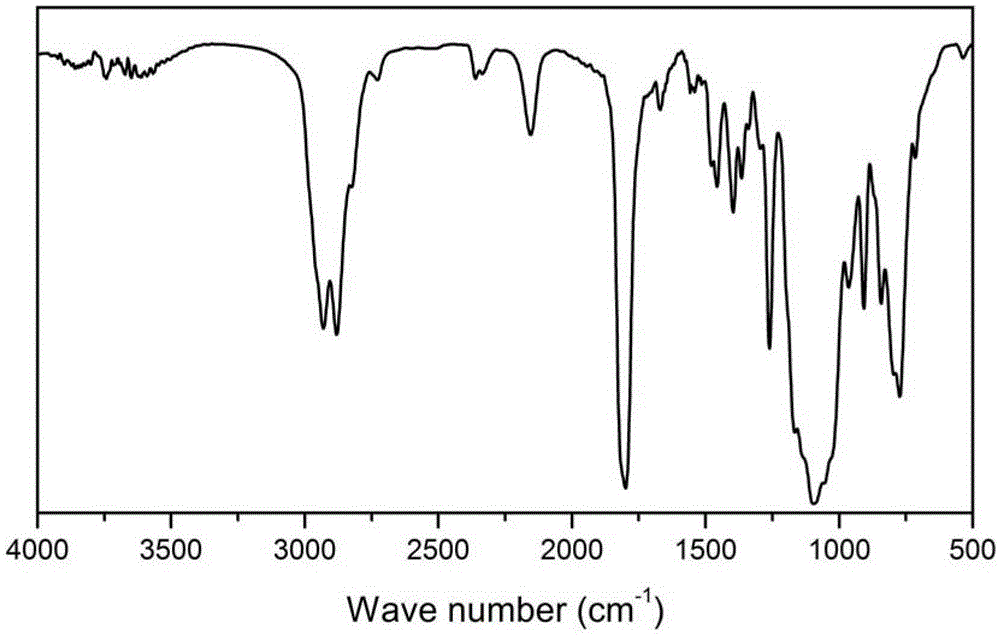

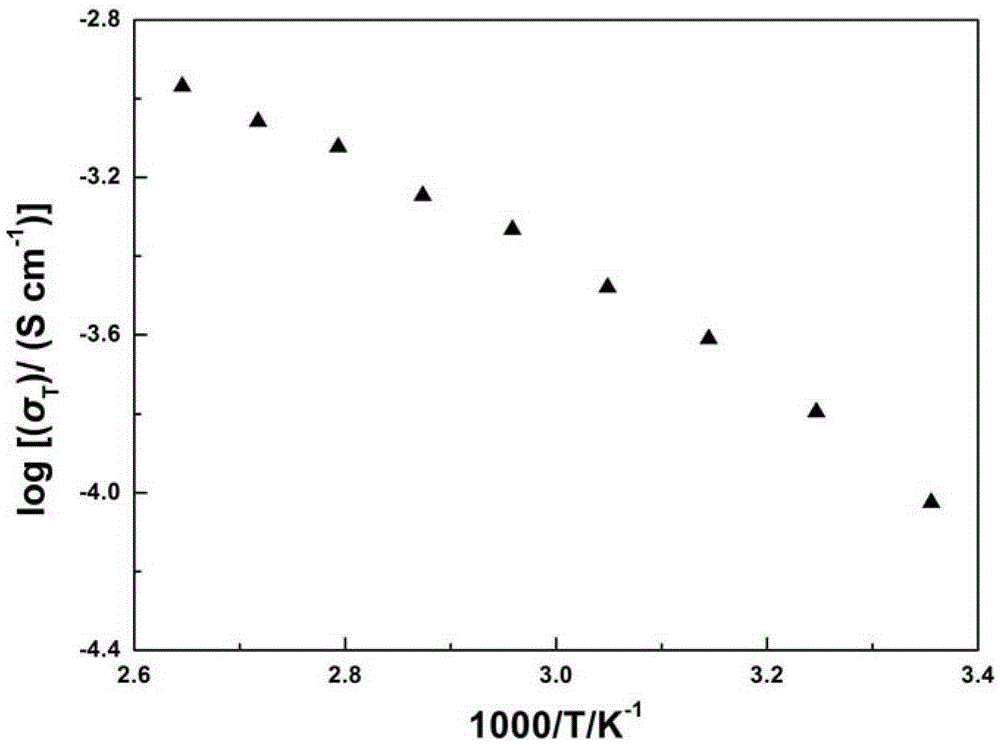

[0044] Take 2g of hydrogen-containing siloxane (molecular weight 1900-2100g / mol), add 0.0322mol of tris(2-methoxyethoxy)vinyl siloxane and vinyl cyclic carbonate, tri( The amount of substance of 2-methoxyethoxy) vinyl siloxane is 0.00970mol (8.82g), the amount of substance of vinyl cyclic carbonate is 0.0225mol (0.526g), that is, the amount of substance of both Quantitative ratio 3:7, 0.01g Castel catalyst was placed in a two-necked flask, 5.673g of anhydrous toluene was added as a solvent, and the reflux reaction was carried out at 110°C for 24h under the protection of argon, and the obtained colloidal polymer was lithium-conducting silicon oxide alkane polymers. In an argon atmosphere, take 1g of the polymer, 0.2g of PVDF (molecular weight 1 million), 0.3g of LiN(SO 2 CF 3 ) 2 Dissolve in 3g of N-methylpyrrolidone and stir until uniform. The solution stirred until uniform was cast-coated on stainless steel, and dried at 80° C. for 36 hours under an argon protective atmos...

Embodiment 2

[0046] Take 2g of hydrogen-containing siloxane (molecular weight 1900-2100g / mol), add 0.0333mol of tris(2-methoxyethoxy)vinyl siloxane and vinyl cyclic carbonate, tri( The amount of substance of 2-methoxyethoxy) vinyl siloxane is 0.0300mol (8.82g), the amount of substance of vinyl cyclic carbonate is 0.00333mol (0.526g), that is, the amount of substance of both Quantitative ratio 9:1, 0.01g Castel catalyst was placed in a two-necked flask, 5.673g of anhydrous toluene was added as a solvent, and refluxed at 110°C for 6h under the protection of argon, the obtained colloidal polymer was lithium-conducting silicon oxide alkane polymers. In an argon atmosphere, take 0.8g of the polymer, 0.15g of PEO (molecular weight 1 million), 0.05g of LiN(SO 2 CF 3 ) 2 Dissolve in 1g of acetonitrile and stir until uniform. The solution stirred until uniform was cast-coated on the lithium iron phosphate positive electrode sheet, and dried at 60° C. for 50 h under a relative vacuum of -70 KPa ...

Embodiment 3

[0048] Take 2g of hydrogen-containing siloxane (molecular weight 1900-2100g / mol), add the total amount of 0.0278mol of vinyl triethoxysilane and allyl methyl carbonate, vinyl triethoxysilane The amount is 0.00278mol (0.450g), the amount of allyl methyl carbonate is 0.0250mol (2.9g), that is, the ratio of the two substances is 1:9, and the 0.133 chloroplatinic acid catalyst is placed in a two-necked flask , adding 3.745g of anhydrous benzene as a solvent, under the protection of nitrogen, reflux at 80°C for 48h, and the obtained colloidal polymer is lithium-conducting siloxane polymer. In an argon atmosphere, take 0.6g of the polymer, 0.3g of PVDF (molecular weight of 700,000), 0.1g of LiC 4 BO 8 Dissolve in 5g of N-methylpyrrolidone and stir until uniform. The solution that was stirred until uniform was cast-coated on stainless steel, and dried at 80°C for 36 hours under a relative vacuum of -85KPa to obtain an electrolyte film with a certain thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com