A method for manufacturing an alignment film, a display panel, and a display device

A production method and technology of alignment film, which are applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of inability to prevent afterimages of ion impurities, and the inability of layered alignment films to be completely delaminated, so as to avoid the formation of afterimages and avoid processes. Complex, reduced enrichment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

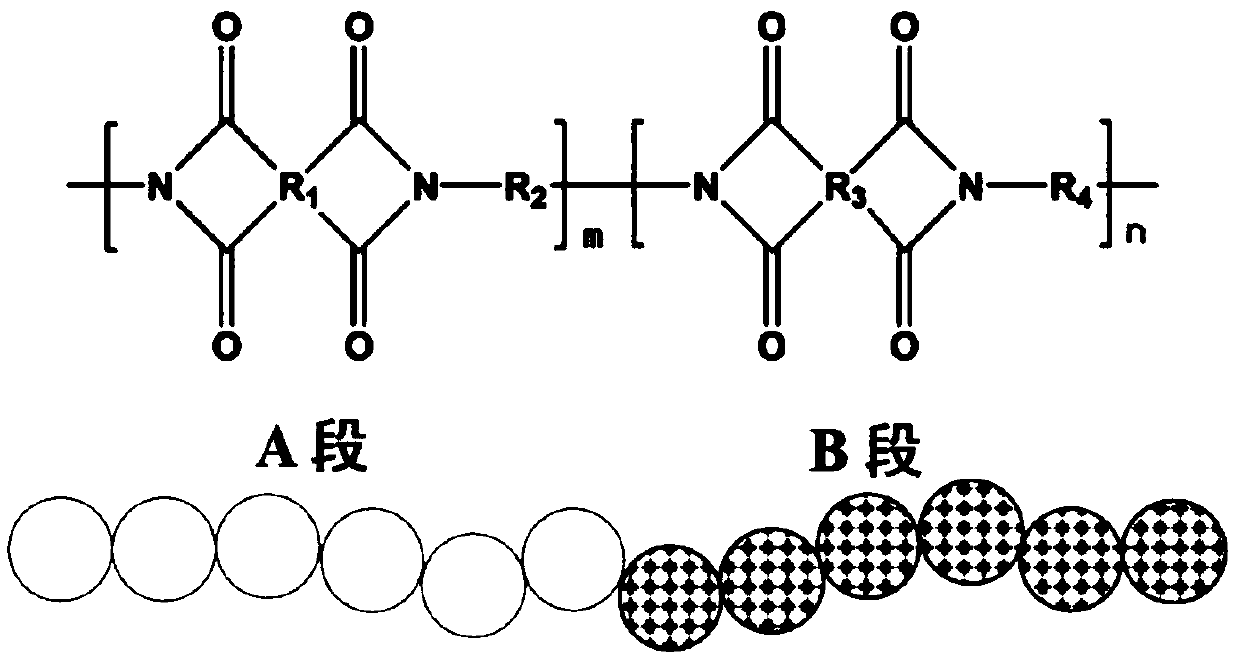

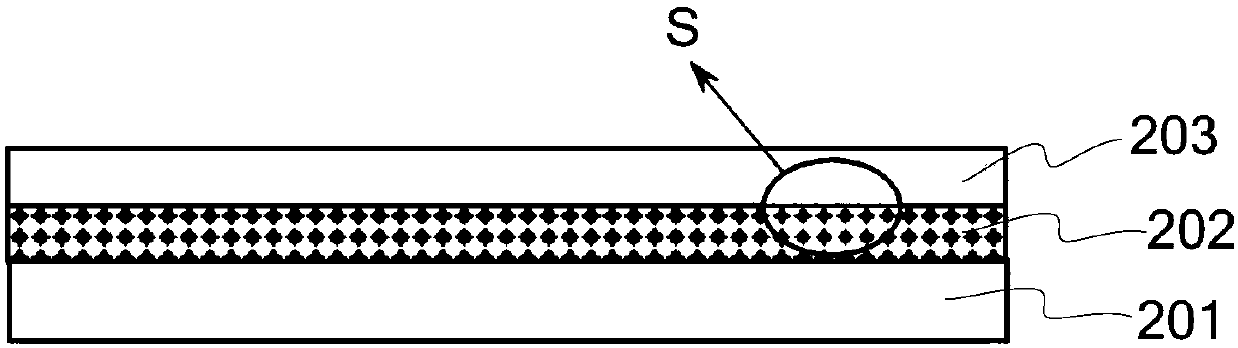

[0040] Aiming at the problems in the prior art that the layered alignment film formed by one-step coating and film formation cannot be completely layered, and the formed alignment film cannot prevent ion impurities in the liquid crystal layer from causing afterimages, the embodiments of the present invention provide A method for manufacturing an alignment film, a display panel and a display device.

[0041] The specific implementations of the method for manufacturing the alignment film, the display panel and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The thickness and shape of each film layer in the drawings do not reflect the real scale, and the purpose is only to illustrate the content of the present invention.

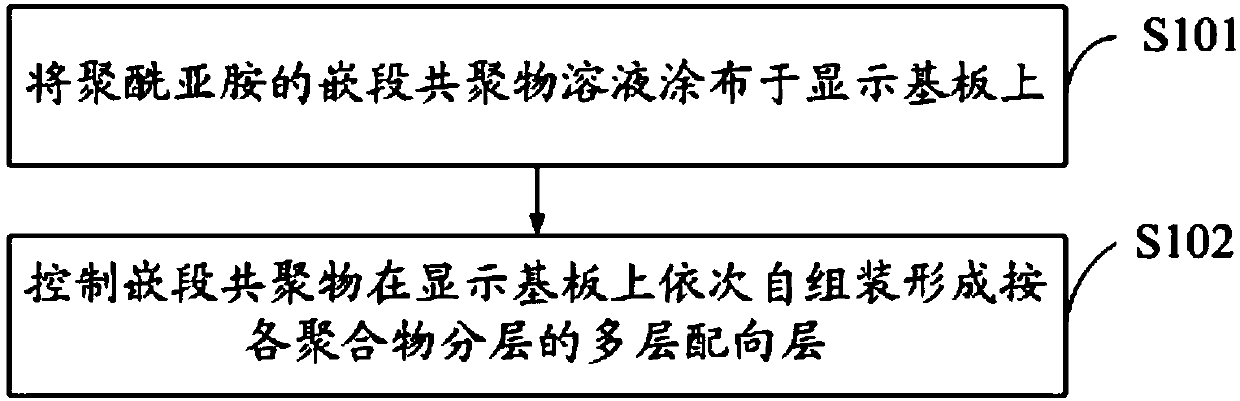

[0042]Embodiments of the present invention provide a method for fabricating an alignment film, such as figure 1 shown, including:

[0043] S101. Coating a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com