Epoxy-resin-modified polyurethane waterproof paint and preparation method thereof

A polyurethane waterproof and epoxy resin technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult adhesion to non-polar substrates, easy sedimentation and delamination of waterproof coatings, shortened service life, etc., to achieve improved Structural stability and mechanical properties, increase chemical crosslink density, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

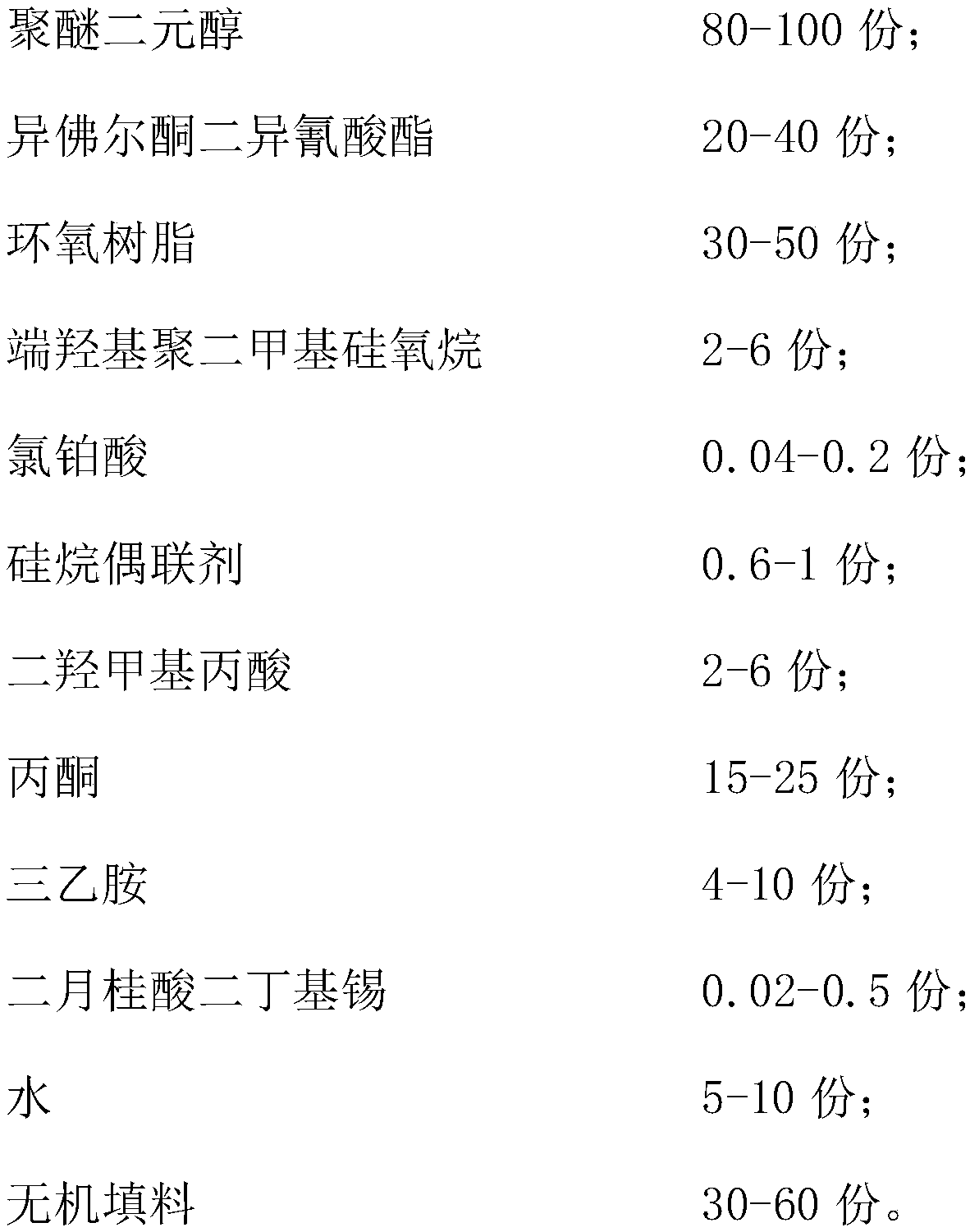

[0023] An epoxy resin modified polyurethane waterproof coating comprises the following components in parts by weight:

[0024]

[0025] The present invention also provides the preparation method of above-mentioned a kind of epoxy resin modified polyurethane waterproof coating, comprises the following steps:

[0026] S1: Heat hydroxyl-terminated polydimethylsiloxane, chloroplatinic acid, and silane coupling agent to 40°C, and then add dropwise epoxy resin, which is polymerized with bisphenol A diglycidyl ether monomer The resulting average molecular weight is 360, the average degree of polymerization is 0.4, and the glycidyl ether type resin with an epoxy value of 0.42 is continuously stirred to carry out condensation reaction until the amount of -OH in the reaction system is reduced by 30%, and the reaction is stopped to obtain polydimethylformaldehyde base siloxane modified epoxy resin;

[0027] S2: In a vacuum environment, heat the polyether diol to 100°C, dehydrate for ...

Embodiment 2

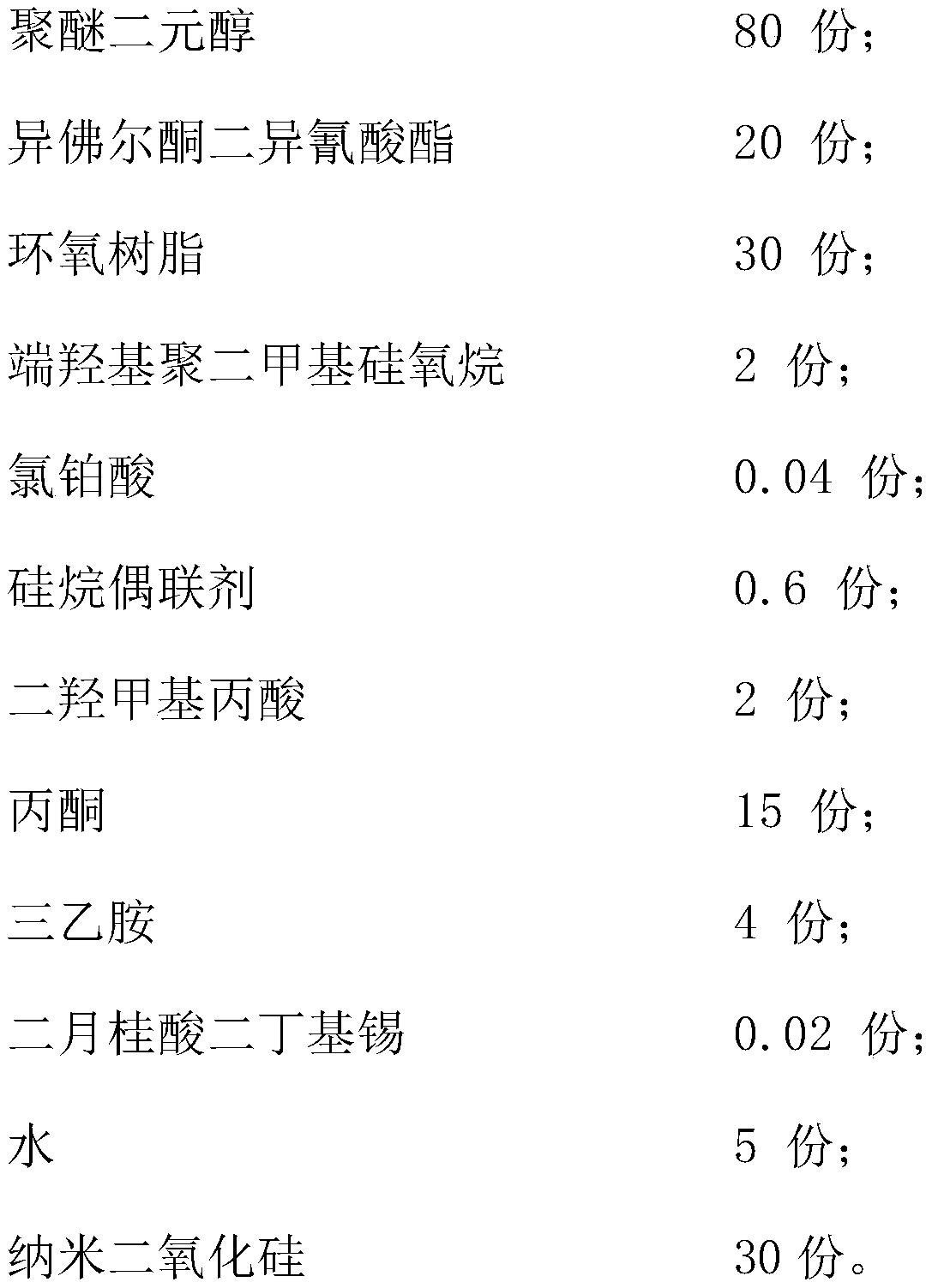

[0031] An epoxy resin modified polyurethane waterproof coating comprises the following components in parts by weight:

[0032]

[0033]

[0034] The preparation method of above-mentioned waterproof paint is with embodiment 1, difference is:

[0035] S1: The condensation reaction temperature is 50°C, the degree of reaction is 45% reduction in the number of -OH, and the epoxy resin used is polymerized from ethylene glycol-glycidyl ether monomer with an average molecular weight of 530 and an average degree of polymerization of 1. Glycidyl ether type resin with a value of 0.51;

[0036] S2: The dehydration temperature is 110°C, and the nucleophilic addition reaction conditions are 70°C and 100KPa nitrogen;

[0037] S3: heat preservation and stirring reaction time is 2h;

Embodiment 3

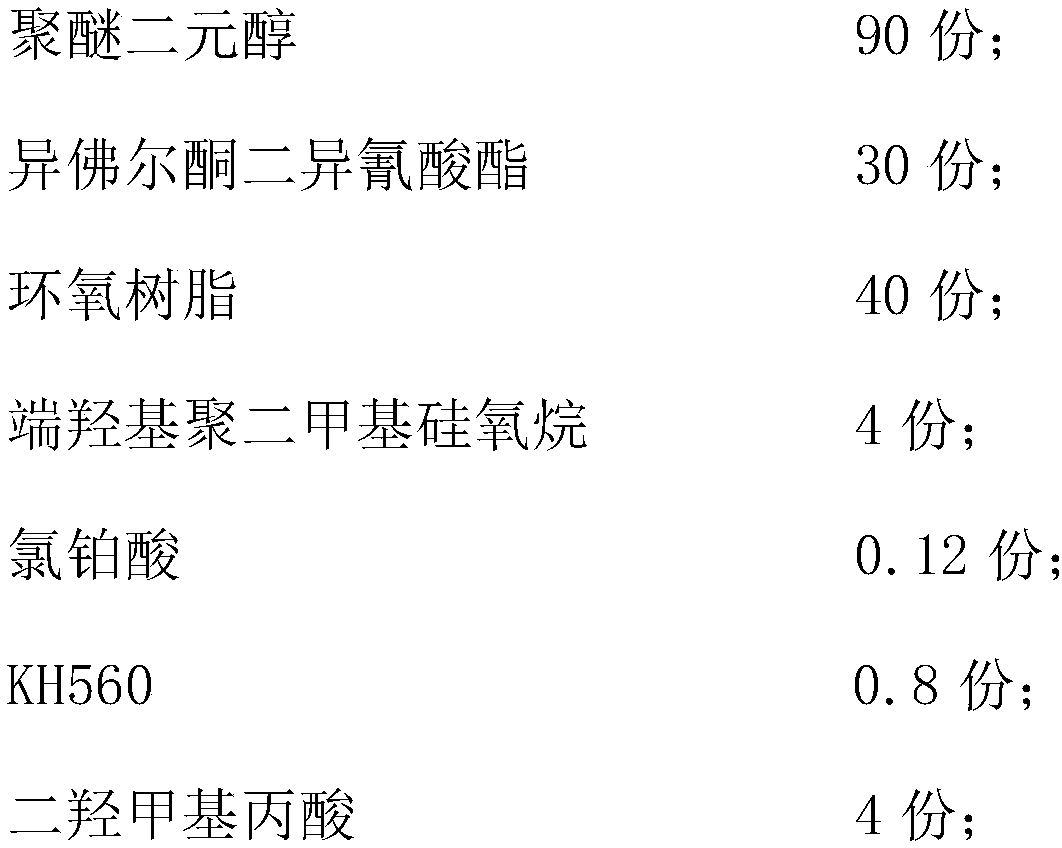

[0039] An epoxy resin modified polyurethane waterproof coating comprises the following components in parts by weight:

[0040]

[0041]

[0042] The preparation method of above-mentioned waterproof paint is with embodiment 1, difference is:

[0043] S1: The condensation reaction temperature is 60°C, the degree of reaction is 60% reduction in the number of -OH, and the epoxy resin used is polymerized from glycerol triglycidyl ether monomer with an average molecular weight of 700 and an average degree of polymerization of 1.6. Glycidyl ether type resin with a value of 0.6;

[0044] S2: The dehydration temperature is 120°C, and the nucleophilic addition reaction conditions are 75°C and 120KPa nitrogen;

[0045] S3: The reaction time of heat preservation and stirring is 3 hours.

[0046] With common epoxy resin modified polyurethane waterproof coating as comparative example, embodiment 1-3 and comparative example are respectively coated on polyethylene, polypropylene, poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com