Tobacco flavor characteristic component analysis method and pretreatment method thereof

A technology for analysis of tobacco flavors and components, which is applied in material separation, analysis materials, preparation of test samples, etc. It can solve the problems of low extraction efficiency of characteristic components, difficulty in flavoring cigarettes, easy adhesion and damage to sampling needles, etc. problems, to achieve the effects of chromatographic separation, accurate qualitative and quantitative, avoiding the loss of aroma substances, and comprehensive aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

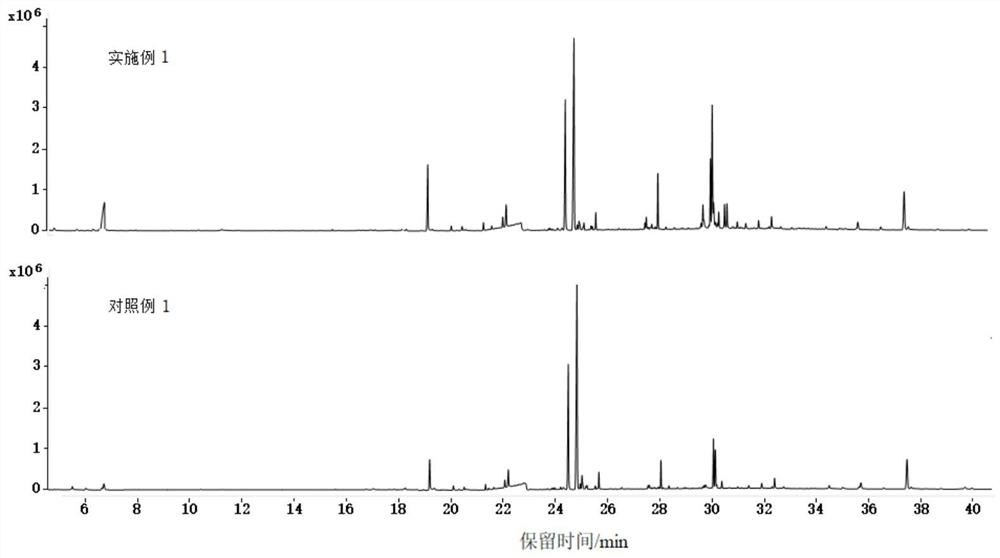

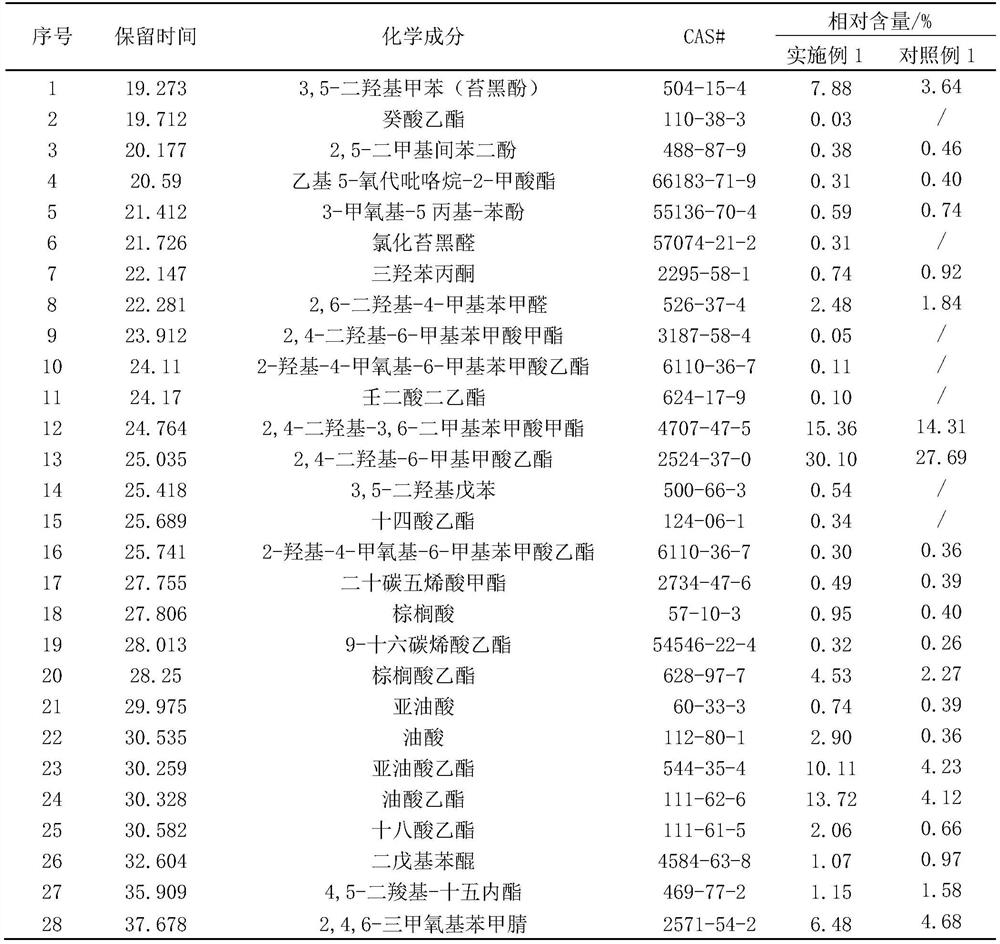

Embodiment 1

[0058] 1. Weigh 5g of commercially available tree moss extract and dissolve it with 100mL of 50% ethanol aqueous solution to obtain a spice diluent for later use;

[0059] 2. Measure 40mL AB-8 macroporous adsorption resin (weak polar resin) into the extraction kettle, first rinse the resin with 100mL absolute ethanol at a flow rate of 2mL / min, and then pump in deionized water at a flow rate of 1mL / min Rinse the resin with water until the effluent is clear; pump all the fragrance diluents into the activated macroporous adsorption resin at a fluidity of 0.5mL / min, pour in liquid carbon dioxide, and at the same time pump anhydrous at a flow rate of 0.1mL / min Ethanol, under the conditions of 10MPa and 55°C, open the pressure reducing valve, and the ethanol carrying the dissolved aroma components is continuously taken out by carbon dioxide at a flow rate of 1.5L / min, and continuously collected for 1 hour. At the same time, the carbon dioxide gas is separated and liquefied after refr...

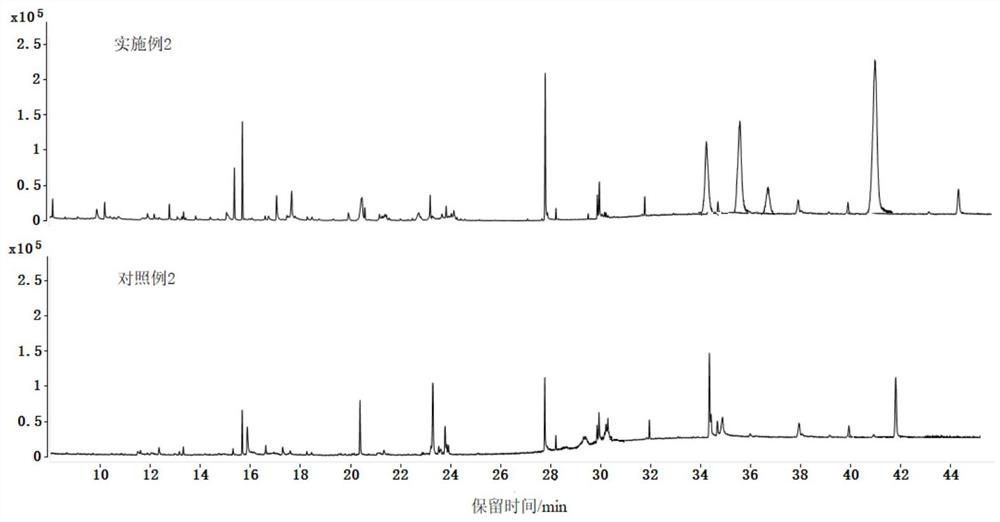

Embodiment 2

[0069] 1. Weigh 10g of commercially available sea buckthorn extract and dissolve it with 120mL of deionized water to obtain a spice diluent for later use;

[0070] 2. Measure 50mL HPD-450 macroporous resin (medium polar resin) into the extraction kettle, first rinse the resin with 80mL absolute ethanol at a flow rate of 2.5mL / min, and then use 50mL deionized water at a flow rate of 1mL / min. The resin was rinsed with a flow rate; all the fragrance diluent was pumped into the activated macroporous resin at a flow rate of 0.8mL / min, liquid carbon dioxide was introduced, and at the same time, a volume ratio of 3:7 was pumped at a flow rate of 0.2mL / min. Alkane ethanol mixed solvent, under the conditions of 10MPa and 50℃, open the pressure reducing valve, the mixed solvent carrying the dissolved aroma components is continuously taken out by carbon dioxide at a flow rate of 1L / min, and continuously collected for 1.0h. At the same time, the carbon dioxide gas is separated after refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com