Process for preparing modified asphalt

A production process and modified asphalt technology, which is applied in the field of asphalt processing, can solve the problems of asphalt being easy to coke, etc., and achieve the effects of good product quality, improved control accuracy, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

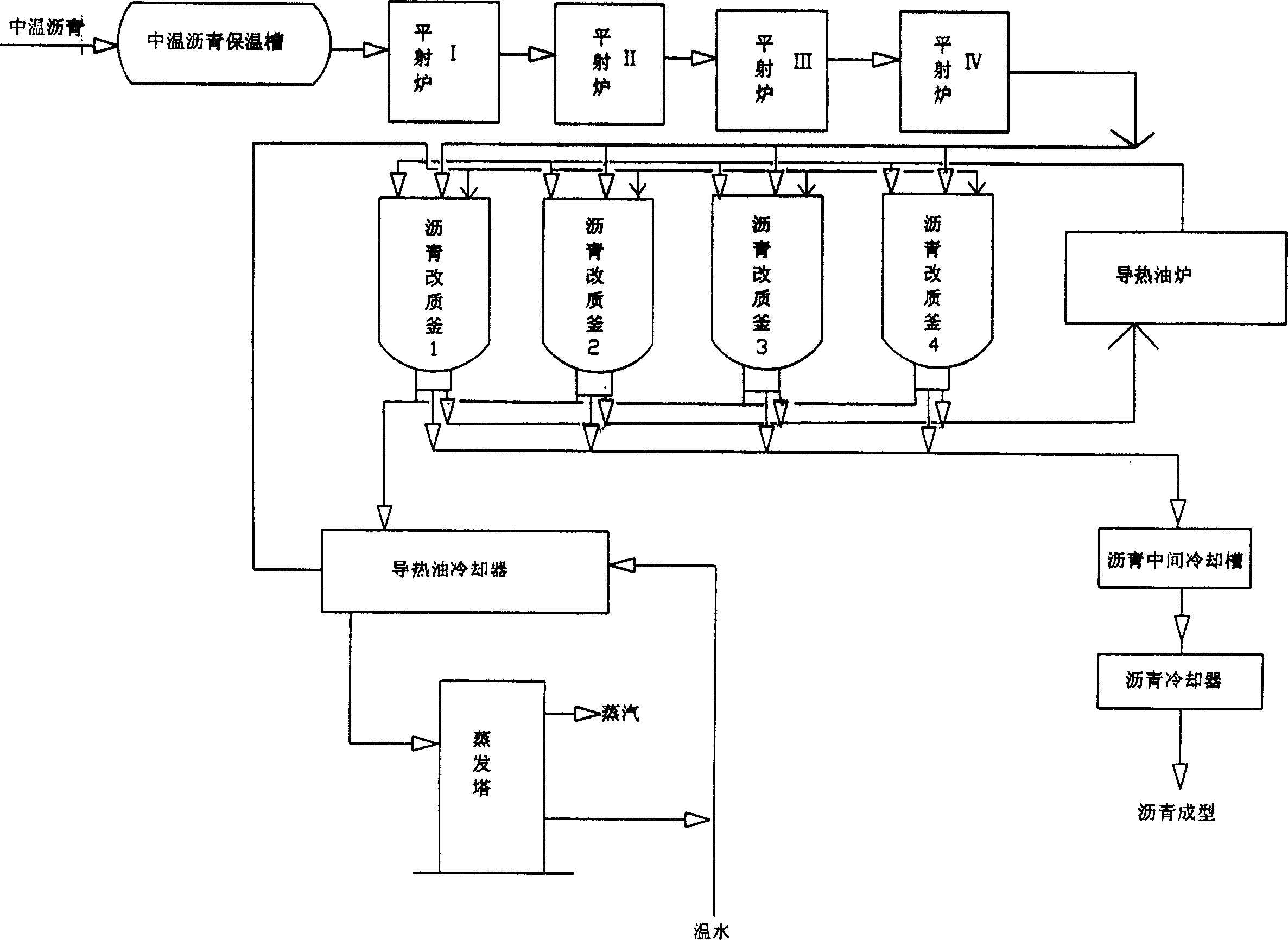

Image

Examples

Embodiment 1

[0020] (1) Sectional heating

[0021] Medium-temperature asphalt raw materials are kept warm in a medium-temperature tank at a temperature of 355°C and 3 / h is continuously sent to the heating system for heating. The heating system is a flat shot furnace, which is divided into 3 sections to heat up, and each section is evenly raised by 10°C to 385°C.

[0022] (2) Modified

[0023] The heated asphalt enters five heat-retaining reforming tanks simultaneously, the reaction temperature is 385°C, and after continuous stirring for 13 hours, the temperature of the reforming tanks is cooled to 170°C, and the cooling time is 6 hours. The heat preservation and cooling of the reforming kettle are completed by the heat transfer oil provided by the heat transfer oil furnace and the heat transfer oil cooler.

[0024] (3) cooling forming

[0025] The modified asphalt is sent to the intermediate cooling tank, and the intermediate cooling tank is 40m 3 / h circulation volume backflow at the...

Embodiment 2

[0027] (1) Sectional heating

[0028] Medium-temperature asphalt raw materials are kept warm in a medium-temperature tank with a temperature of 360°C and 3 / h is continuously fed into the heating system for heating. The heating system consists of four flat-fire furnaces, each of which is divided into four sections, and the temperature is raised in four sections.

[0029] (2) Modified

[0030] The heated bitumen is simultaneously fed into 5 reforming tanks respectively, the reaction temperature is 392°C, after continuous stirring for 11 hours, the temperature of the reforming tank is cooled to 175°C, and the cooling time is 7 hours. The heat preservation and cooling of the reforming kettle are completed by the heat transfer oil provided by the heat transfer oil furnace and the heat transfer oil cooler.

[0031] (3) cooling forming

[0032] The modified asphalt is sent to the intermediate cooling tank, and the intermediate cooling tank is 45m 3 / h circulation volume backflow...

Embodiment 3

[0034] (1) Sectional heating

[0035] Medium-temperature asphalt raw materials are kept warm in a medium-temperature tank at a temperature of 365°C and 3 / h is continuously sent to the heating system for heating. The heating system consists of three flat-fire furnaces, each of which is divided into one section, and the heating is divided into three sections.

[0036] (2) Modified

[0037] The heated asphalt enters 5 reforming tanks simultaneously, the reaction temperature is 395°C, after continuous stirring for 10 hours, the temperature of the reforming tanks is cooled to 170°C, and the cooling time is 6 hours. The heat preservation and cooling of the reforming kettle are completed by the heat transfer oil provided by the heat transfer oil furnace and the heat transfer oil cooler.

[0038] (3) cooling forming

[0039] The modified asphalt is sent to the intermediate cooling tank, and the intermediate cooling tank is 50m 3 / h circulation volume backflow at the same time wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com