Biological asphalt for road as well as preparation device and preparation method of biological asphalt

A bio-asphalt and road technology, applied in the direction of melting and processing tar asphalt/petroleum asphalt/natural asphalt, etc., can solve the problems of strong temperature sensitivity and poor high temperature performance of bio-asphalt, and achieve low temperature sensitivity, excellent performance and high temperature performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, the prepared bio-asphalt for roads is made of the following raw materials in weight percentage: 20% of biomass heavy oil, 74% of base asphalt, 5% of methanol, and 1% of low-density polyethylene.

[0042] When actually preparing bio-asphalt for roads, the mass percentages of the above raw materials can be adjusted accordingly according to specific needs.

[0043] In this embodiment, the base asphalt is No. 90 asphalt.

[0044] In this embodiment, the biomass heavy oil is the remaining heavy oil after the biomass oil is extracted from gasoline and diesel oil, and its specific gravity is 0.82-0.95; the biomass oil is a liquid oil obtained by pyrolysis of biomass .

[0045] Moreover, the biomass is wood chips, corn stalks, cotton stalks or wheat straws.

[0046] In this embodiment, the biomass is sawdust.

[0047] In the present embodiment, the density of low-density polyethylene is 0.915g / cm 3 ~0.940g / cm 3 .

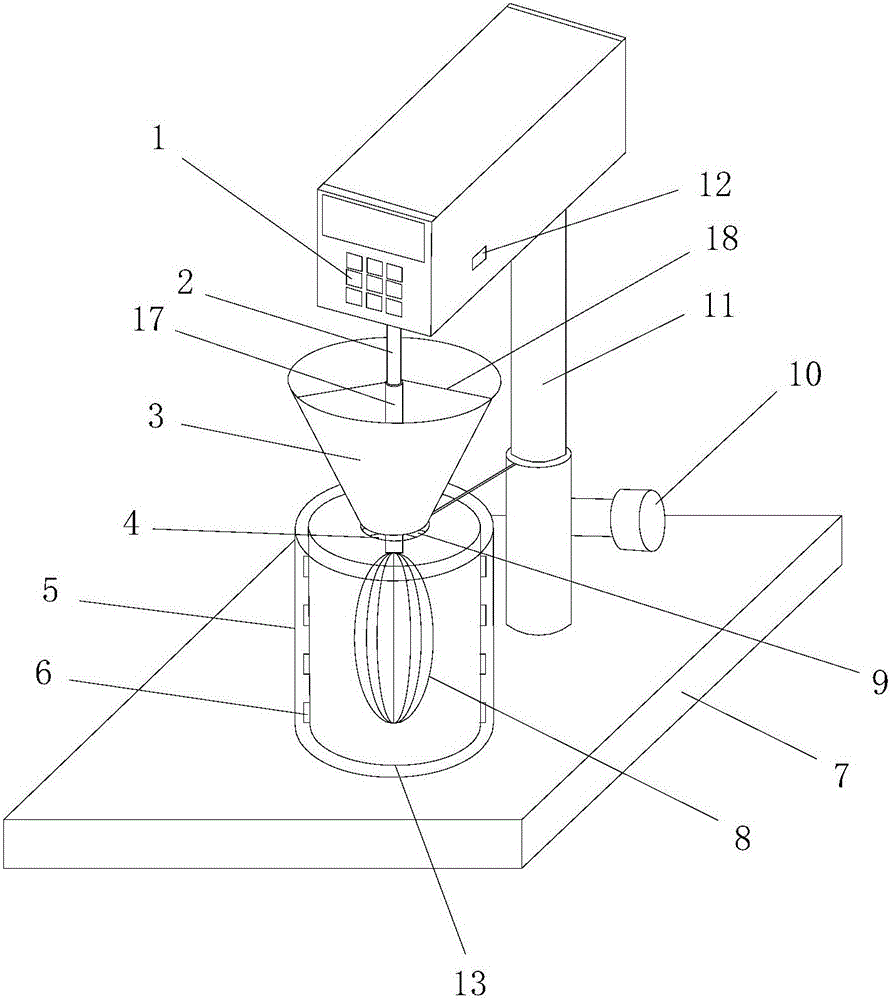

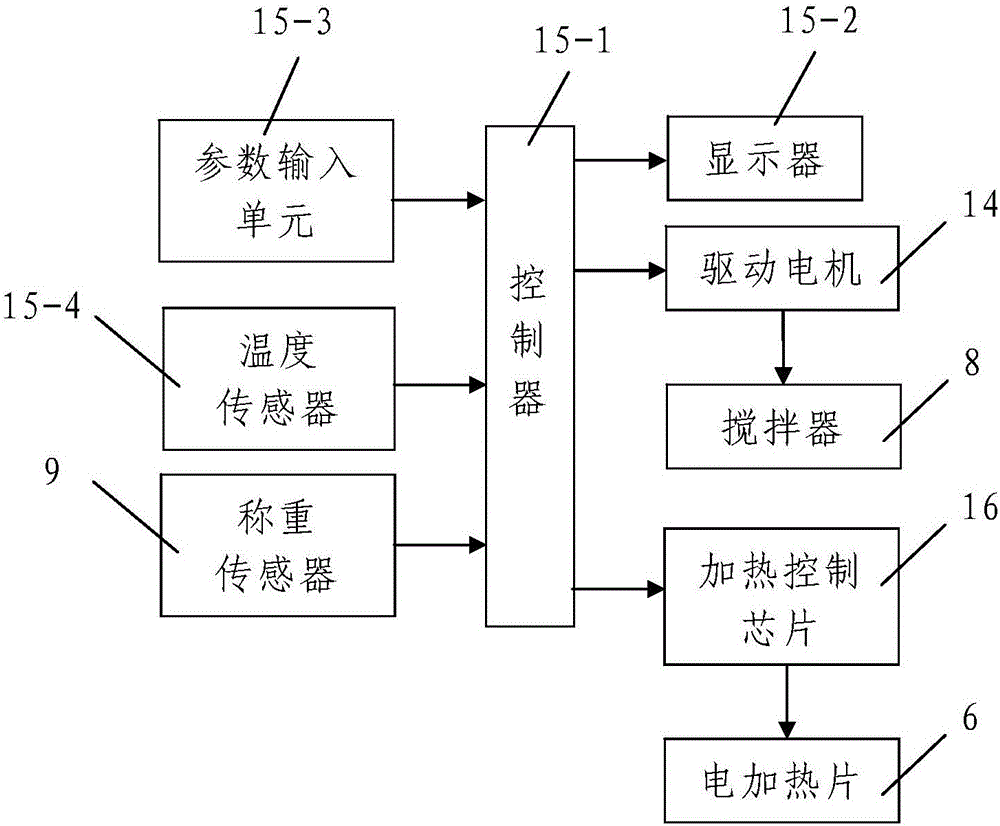

[0048] Such as figure 1 , figure 2 Th...

Embodiment 2

[0070] In this example, the prepared bio-asphalt is made of the following raw materials in weight percentage: 20% of biomass heavy oil, 70% of base asphalt, 5% of methanol, and 5% of low-density polyethylene.

[0071] In this example, the preparation device used is the same as that in Example 1.

[0072] In the present embodiment, the preparation method adopted comprises the following steps:

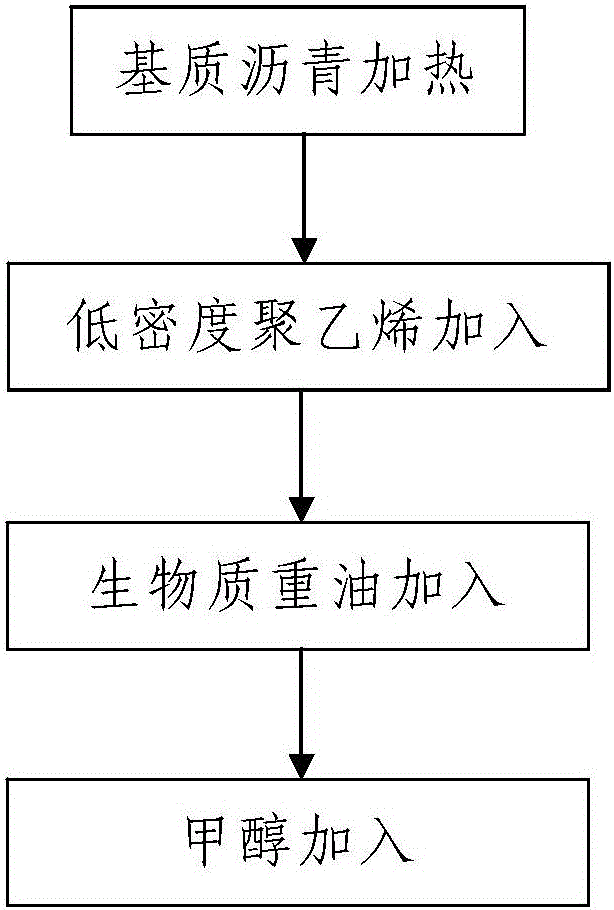

[0073] Step 1. Base asphalt heating: heat base asphalt to temperature T1, where T1=140°C;

[0074] Step 2, adding low-density polyethylene: under the condition of temperature T1, add low-density polyethylene to the heated base asphalt in step 1, and stir for 0.5h at a stirring rate of 3000r / min to obtain the first mixture ;

[0075] Step 3, adding biomass heavy oil: under the condition of temperature T1, add the biomass heavy oil preheated to 60°C into the first mixture described in step 2, and stir for 0.5h at a stirring rate of 3000r / min, Obtain the second mixture;

[0076] Step 4,...

Embodiment 3

[0082] In this example, the prepared bio-asphalt is made of the following raw materials in weight percentage: 10% of biomass heavy oil, 80% of base asphalt, 5% of methanol, and 5% of low-density polyethylene.

[0083] In this example, the preparation device used is the same as that in Example 1.

[0084] In the present embodiment, the preparation method adopted comprises the following steps:

[0085]Step 1. Heating base asphalt: heating base asphalt to temperature T1, where T1=160°C;

[0086] Step 2, adding low-density polyethylene: under the condition of temperature T1, add low-density polyethylene to the heated base asphalt in step 1, and stir for 1.5h at a stirring rate of 500r / min to obtain the first mixture ;

[0087] Step 3, adding biomass heavy oil: under the condition of temperature T1, add the biomass heavy oil preheated to 60°C into the first mixture described in step 2, and stir for 1 hour at a stirring rate of 500r / min to obtain the second mixture;

[0088] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com