Coated carbonaceous particles particularly useful as electrode materials in electrical storage cells, and methods of making the same

A technology of coating particles and carbon particles, which is applied in the direction of alkaline battery electrodes, non-aqueous electrolyte battery electrodes, battery electrodes, etc., can solve the problems of low bulk density, limited electrode density, and difficult processing, and achieve high efficiency and powder flow Good performance and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

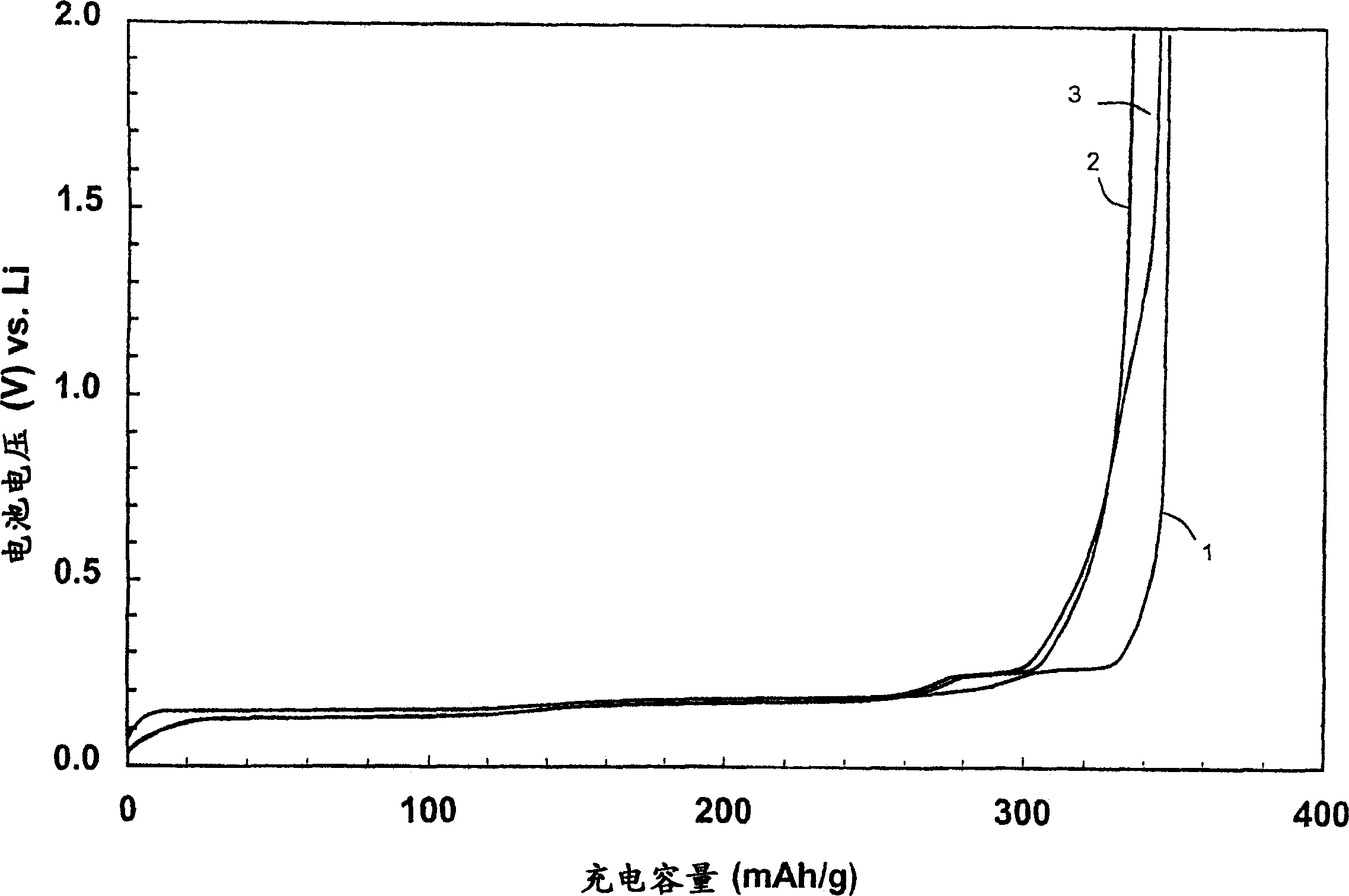

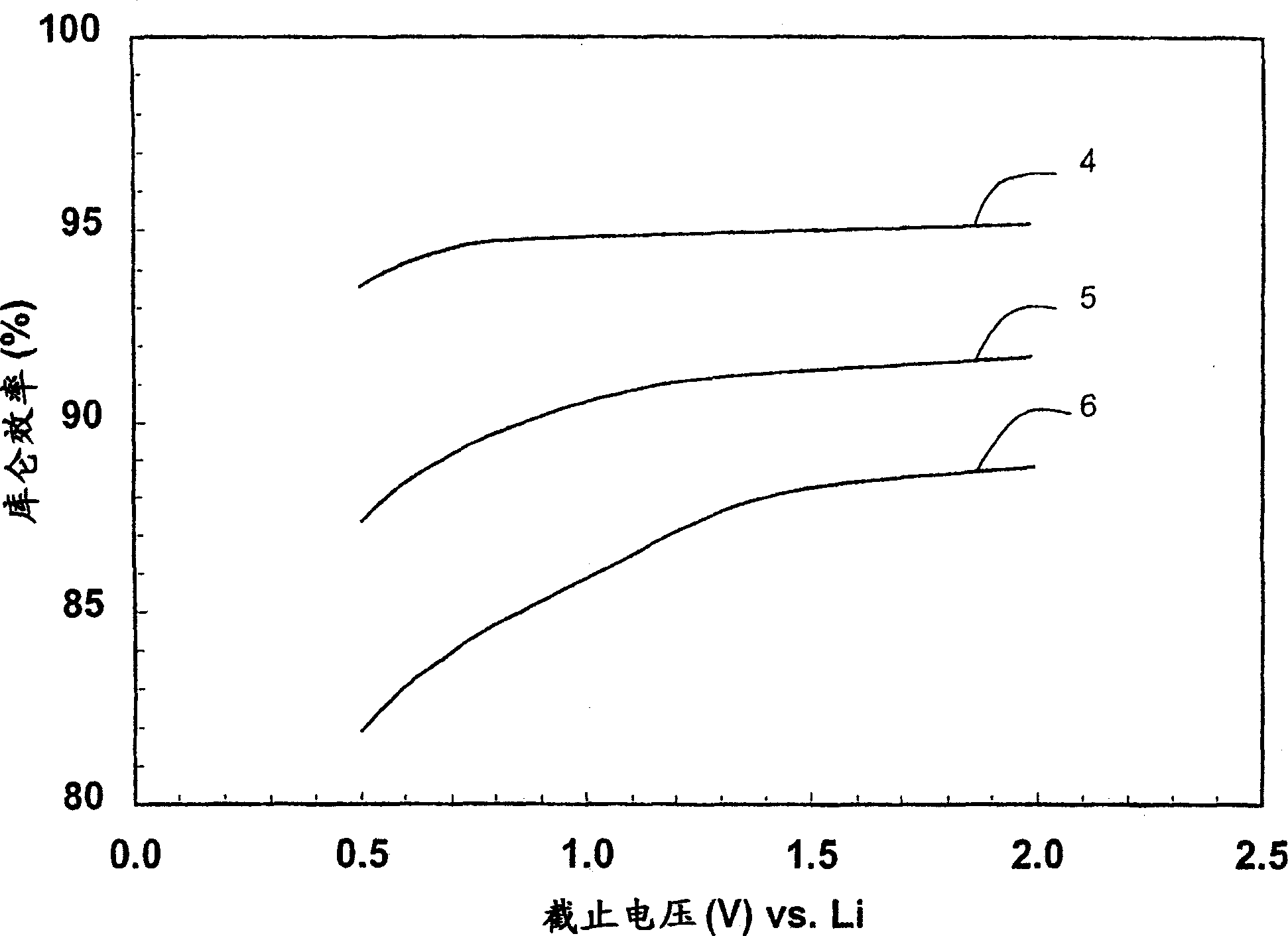

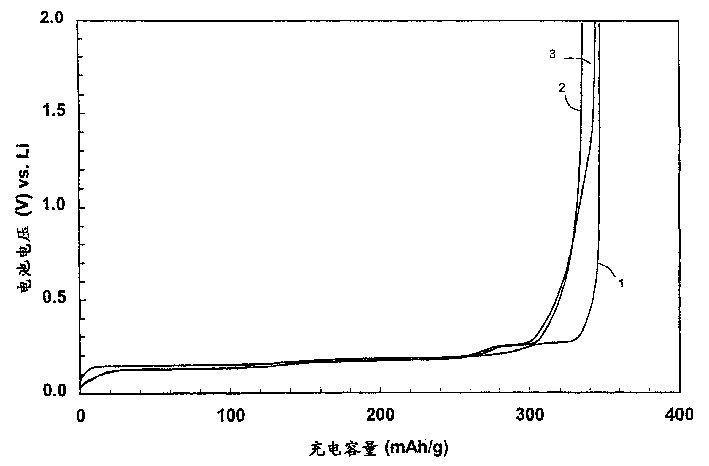

Embodiment 1

[0080] Carbon-containing powders were prepared as follows. "Fresh" granular needle coke is first milled with a hammer mill and then ground into a fine powder with a jet mill. Afterwards, the carbonaceous particles obtained by grinding were sieved to remove particles smaller than 1 μm. The particle size of the resulting carbon-containing powder is about 0.5-50 μm, and the average particle size is about 15-20 μm.

[0081] 4g Tetralin® (C 10 h 12 4 g of low-melting petroleum pitch (210°C Mettler softening point, 75% Alcor carbon residue, isotropic petroleum pitch 6 h 4 (C 2 h 3 ) 2 )mix. The contents of the first beaker were gradually added to the second beaker, and after the addition the resulting mixture was heated with continuous stirring and held at 128°C for 15 minutes. The heat was then removed and the mixture was cooled to ambient temperature (approximately 22°C) while maintaining continuous stirring. The resulting solid was removed from the cooled mixture by firs...

Embodiment 2

[0091] Reference Example 1 Another sample of coated carbon-containing powder particles was prepared following the processing steps described above. However, according to this example, 8.5 g Tetralin® (C 10 h 12 ) 8.5 g of the low-melting petroleum pitch described in Example 1 was added to the first laboratory-type beaker. The contents of the second laboratory beaker were kept the same as in Example 1, but the final dry weight of the dried coated powder particles recovered was about 22.3 g. Based on this result, it was determined that the coating on the coated carbonaceous powder particles accounted for about 10% by weight of the total mass of the coated carbonaceous powder particles. These dried particles were then mixed with 9 g of 3.8 wt% sodium nitrate (NaNO 3 ) (A.C.S reagent, sold by J.T. Baker, Inc.) aqueous solution was mixed thoroughly. The mixture was then dried under vacuum at 80°C. The dried mixture was then oxidized and heat treated according to the procedure ...

Embodiment 3

[0094] Reference Example 1 Another sample of coated carbon-containing powder particles was prepared following the processing steps described above. However, according to the example provided, will be added to 10 g Tetralin® (C 10 h 12) of 10 g of the low-melting petroleum pitch described in Example 1 was added to the first laboratory beaker. The contents of the second laboratory beaker were kept the same as in Example 1, but the final dry weight of the dried coated powder particles recovered was about 22.7 g. Based on this result, it was determined that the coating on the coated carbon-containing powder particles accounted for about 12% by weight of the total mass of the coated carbon-containing powder particles. Subsequently, these dry particles were mixed with 9 g of 4.5 wt% sodium nitrate (NaNO 3 ) (A.C.S reagent, sold by J.T. Baker, Inc.) aqueous solution was mixed thoroughly. The mixture was then dried under vacuum at 80°C. The dried mixture was then oxidized and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com