Single-layer kaolin modified ultrafine heavy calcium carbonate and preparation method thereof

A technology of heavy calcium carbonate and kaolin, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve problems such as large specific surface area, high surface energy, and easy powder agglomeration, and achieve simple operation process, Reduce agglomeration and overlap, and design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

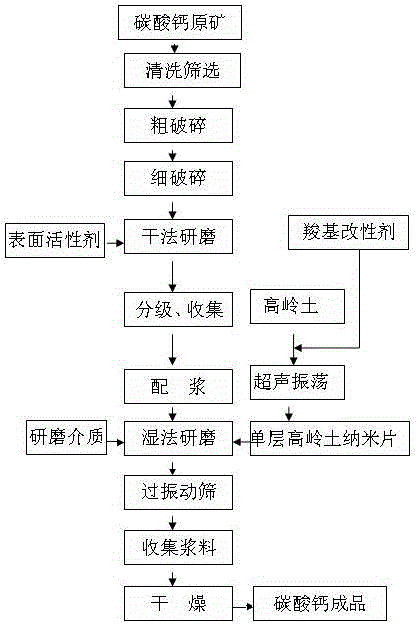

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of monolayer kaolin nanosheets

[0024] Add kaolin powder into tap water, ultrasonically vibrate for 0.5-12h, add carboxyl modifier proportional to kaolin nanosheets, mechanically stir or ultrasonically vibrate for 1-4h, stir it evenly with nitrogen bubbling, and then heat up to 60 °C. o C, gradually add 1.5M sodium hydroxide solution dropwise to adjust the pH of the reaction system to 7-12, and heat to 90 after the reaction for 0.5-2h o C, continue the reaction for 1-4h, the reaction product is washed three times with tap water, centrifuged, and dried in a vacuum drying box for 24h to obtain monolayer kaolin nanosheets; the carboxyl modifier used is sodium alginate, and the seaweed The mass ratio of sodium to ground calcium carbonate is 1:5.

[0025] (2) Preparation of single-layer kaolin modified ground calcium carbonate

[0026] The calcium carbonate coarse material with a diameter of less than 5 cm is sent into the grinding machine, and the surfact...

Embodiment 2

[0032] (1) Preparation of monolayer kaolin nanosheets

[0033] Add kaolin powder into tap water, ultrasonically vibrate for 0.5-12h, add carboxyl modifier proportional to kaolin nanosheets, mechanically stir or ultrasonically vibrate for 1-4h, stir it evenly with nitrogen bubbling, and then heat up to 60 °C. o C, gradually add 1.5M sodium hydroxide solution dropwise to adjust the pH of the reaction system to 7-12, and heat to 90 after the reaction for 0.5-2h o C, continue the reaction for 1-4h, the reaction product is washed three times with tap water, centrifuged, and dried in a vacuum drying oven for 24h to obtain single-layer kaolin nanosheets; the carboxyl modifier used is sodium carboxymethyl cellulose, The mass ratio of the sodium carboxymethyl cellulose to the ground calcium carbonate is 1:200.

[0034] (2) Preparation of single-layer kaolin modified ground calcium carbonate

[0035] The calcium carbonate coarse material with a diameter of less than 5 cm is sent into ...

Embodiment 3

[0041] (1) Preparation of monolayer kaolin nanosheets

[0042] Add kaolin powder into tap water, ultrasonically vibrate for 0.5-12h, add carboxyl modifier proportional to kaolin nanosheets, mechanically stir or ultrasonically vibrate for 1-4h, stir it evenly with nitrogen bubbling, and then heat up to 60 °C. o C, gradually add 1.5M sodium hydroxide solution dropwise to adjust the pH of the reaction system to 7-12, and heat to 90 after the reaction for 0.5-2h o C, continue the reaction for 1-4h, the reaction product is washed three times with tap water, centrifuged, and dried in a vacuum drying oven for 24h to obtain single-layer kaolin nanosheets; the carboxyl modifier used is polyacrylamide, and the polymer The mass ratio of acrylamide to ground calcium carbonate is 1:1000.

[0043] (2) Preparation of single-layer kaolin modified ground calcium carbonate

[0044] The calcium carbonate coarse material with a diameter of less than 5 cm is sent into the grinding machine, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com