Granular vinyl chloride resin for paste processing and process for producing same

A polyvinyl chloride resin and polyvinyl chloride paste technology, applied in chemical instruments and methods, screens, grids, etc., can solve the problems of reduced classification speed, increased equipment costs, and reduced quality of resin dispersions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

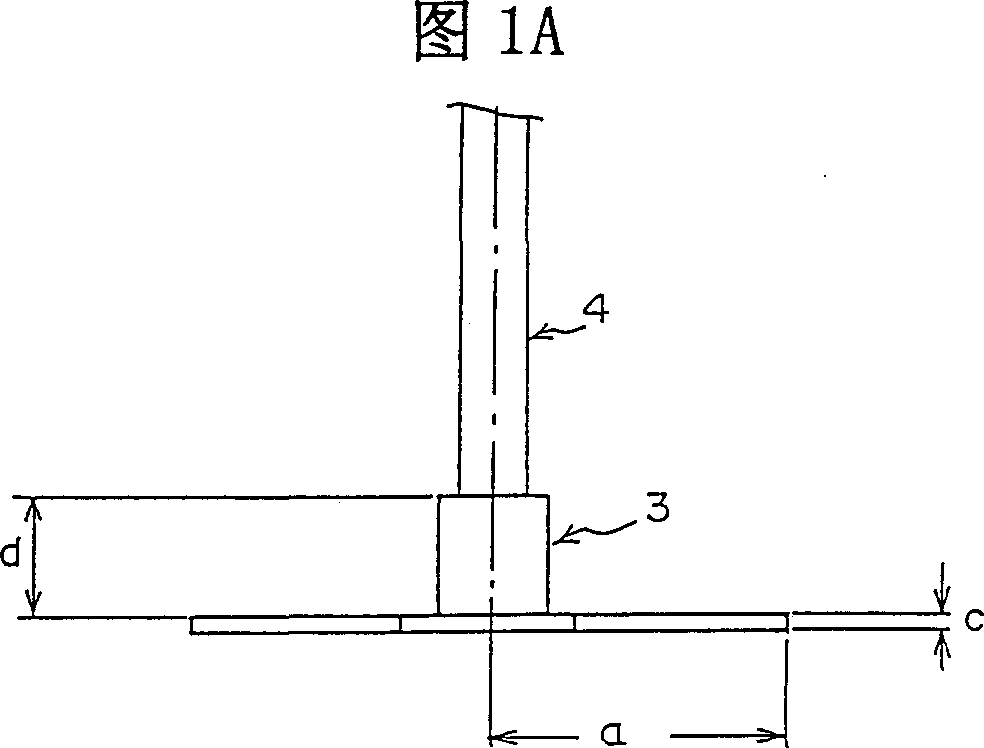

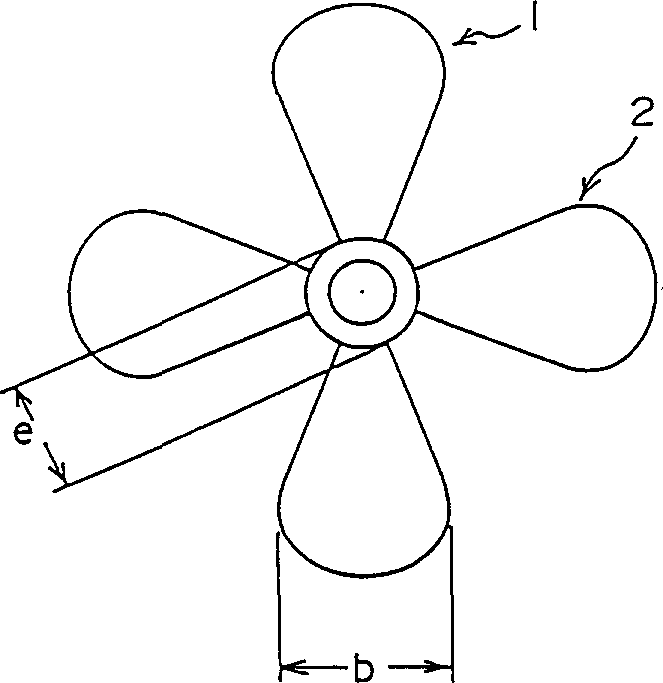

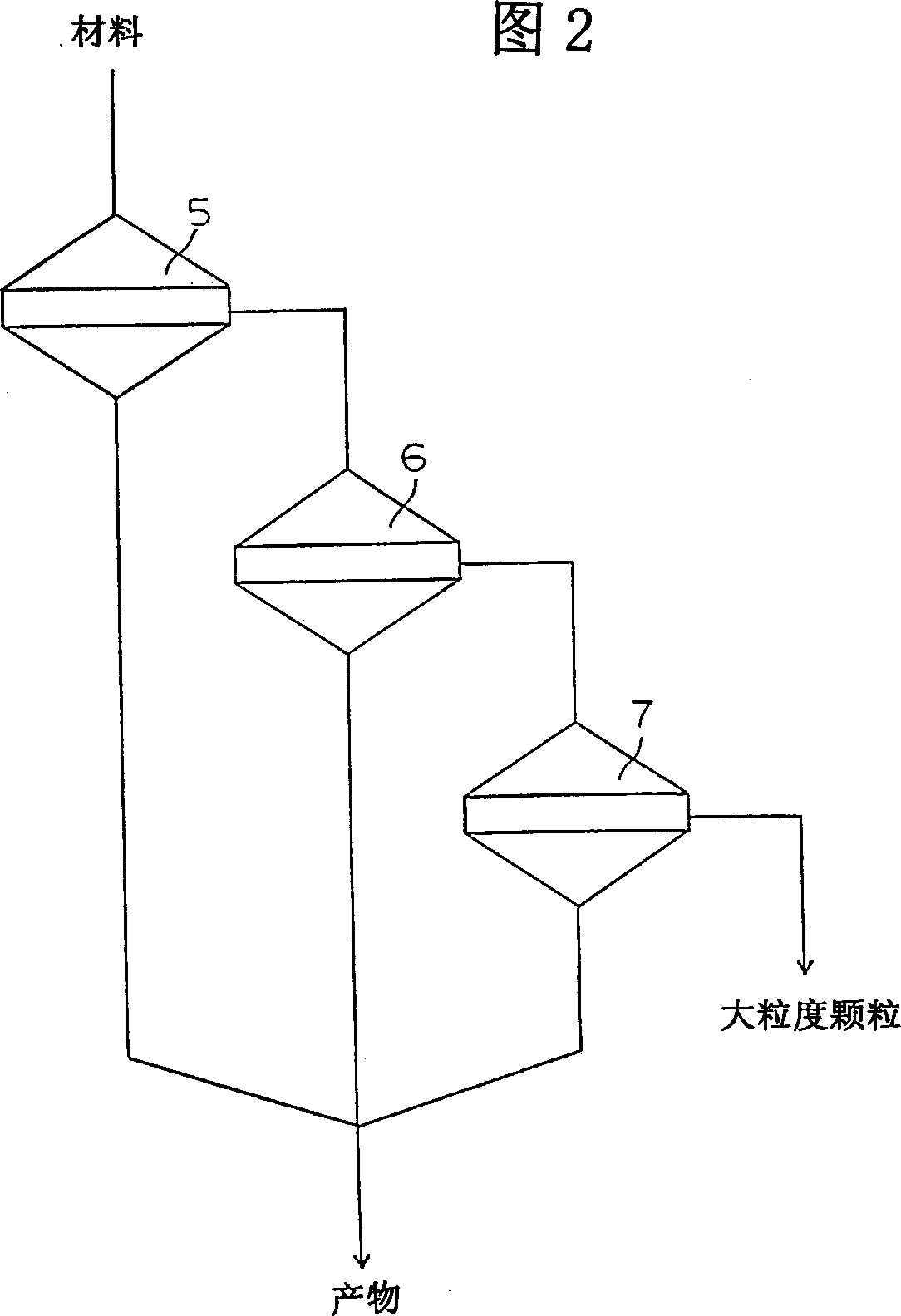

[0093] 100 parts by weight of polyvinyl chloride resin containing 92 (weight)% of particle components with a mode particle size of 1.2 microns and 8 (weight)% of particles with a mode particle size of 0.2 microns and 1 ( weight) parts sodium dodecylbenzene sulfonate, according to the method for inoculating emulsion polymerization to make the polyvinyl chloride resin aqueous dispersion that solid content concentration is 46 (weight)%. A spray drying tower equipped with a turntable atomizer (210mm in diameter and 15,000rpm in rotation speed) is used. The absolute humidity of the heated air is 0.01 kg of water / kg of air, the air inlet temperature is 130°C, and the outlet temperature is 55°C. The aqueous dispersion was spray-dried under the condition of ℃. The granular powder obtained by spray drying has a vibration frequency of 36 kHz, an ultrasonic power (maximum power of 200 watts) output of 70%, and a low-speed vibration motor (output of 0.75 kilowatts, frequency of 1400 Hz) a...

Embodiment 2

[0096] The granular powder obtained by polymerizing and drying in the same steps as in Example 1 was classified by the steps in Example 1 (except that the low-speed vibrating motor was not running) with an ultrasonic vibrating sieve. Because the low-speed vibrating motor stops running, the powder that has passed through the sieve will accumulate under the vibrating sieve, so the time required for classification is about 20 times that of Example 1.

[0097] The water content of the polyvinyl chloride resin granule that is used for making paste is 0.5 (weight) %, and average particle diameter is 40.0 microns, and the particle content of particle diameter less than 10 microns is 8.1 (weight). )%, and the content of particles with a particle size greater than 149 microns is 0.0010 (weight)%. The bulk density (loose) is 0.550 g / cm 3 , the angle of repose is 34 degrees. In the powder adhesion test, no powder was found to adhere to the horizontal straight pipe. In the dispersibili...

Embodiment 3

[0112] Aqueous dispersions of polyvinyl chloride resins prepared according to microsuspension polymerization, with a mode particle size (calculated by weight) of 1.8 microns and a particle size distribution width of 0.2-6 microns (solid component concentration of 48 (weight) %) carry out spray drying according to the following steps: the dispersion is sprayed with the rotating speed of 19200rpm by the rotating disc type atomizer (diameter 210 millimeters); Adopt absolute humidity to be 0.01 kilogram water / kg air, be heated to 170 The air at °C is passed from the top of the tower to the bottom of the tower in parallel with the dispersion; and the outlet temperature at the bottom of the tower is adjusted to 55 °C. The bulk density (loose) of the resin granular powder obtained after drying is 0.51 g / cubic centimeter, the angle of repose is 40 ± 1 degree, and the particle size is 109 microns or more than 109 microns. The particle content is 0.5 (weight )% and particles with a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com