Asphalt melting device

A melting device and asphalt technology, applied in the direction of melting and processing tar asphalt/petroleum asphalt/natural asphalt, etc., can solve the problems of polluting the environment slag, energy consumption, difficult cleaning, etc., to reduce equipment energy consumption, meet environmental protection requirements, and easily The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

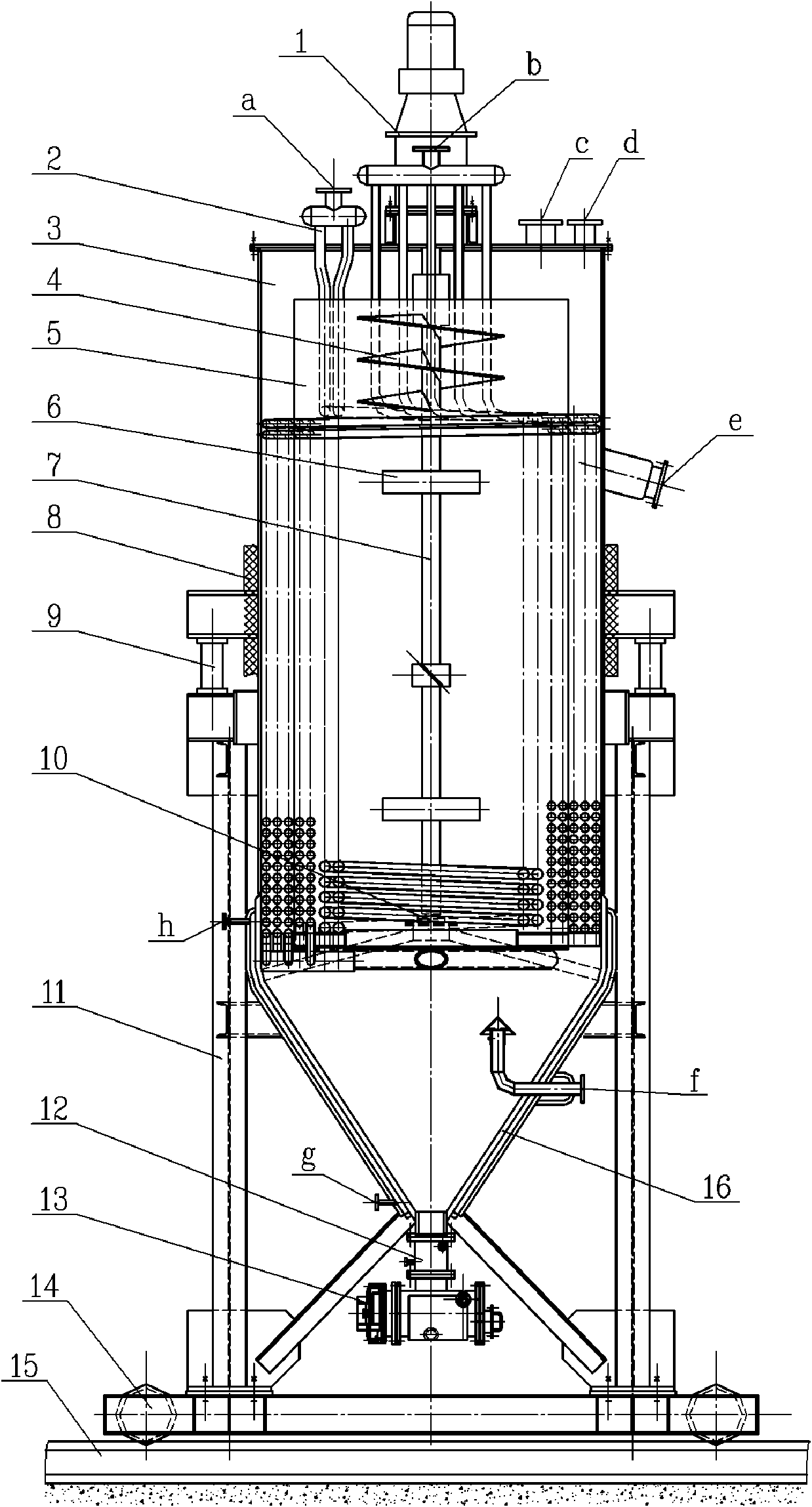

[0019] Embodiment: first the mobile car 14 is installed on the track 15; then the support 11 is fixed on the mobile car 14 with bolts; secondly, 3 temporary support seats slightly higher than the load cell 9 are installed on the support 11 in the circumferential direction; Weld the support frame 10 to the inner lower section of the straight cylinder section of the tank body 3; then hoist the tank body 3 on the temporary support seat on the bracket 11; , Outer assembly according to the set number of coils and the diversion inner cylinder 5, set the number of coils and the size of the heating coil to calculate the heat exchange area according to the production capacity of the device, and then convert the coil size and number of coils before configuring. After the assembly is completed, it is hoisted into the tank body 3 and installed on the support frame 10; then the transmission part in the transmission stirring device 1 is assembled with the propeller blade 4, the straight blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com