Preparation method and device of high-softening-point asphalt, high-softening-point asphalt, and binding agent prepared from high-softening-point asphalt

A technology of high softening point asphalt and preparation device, which is applied in the direction of melting and processing tar asphalt/petroleum asphalt/natural asphalt, chemically processing tar asphalt/petroleum asphalt/natural asphalt, and asphalt material binder, etc. Uniform and high softening point special asphalt quality is not stable enough, the average softening point of asphalt is not high, etc., to achieve the effect of stable quality index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of high softening point asphalt, the step comprises:

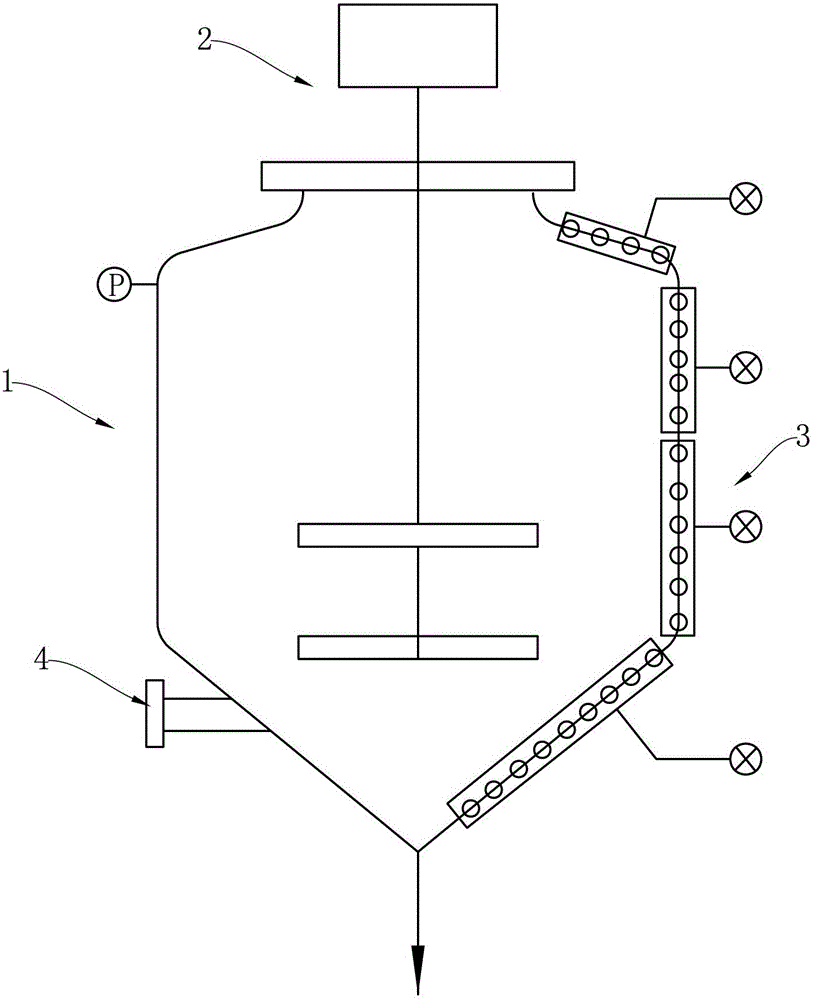

[0036] S1. Import the modified pitch into the monomer container 1, and pass an inert gas into the monomer container 1. The inert gas is nitrogen, and the heating temperature of the four-stage electric heater 3 is sequentially adjusted from top to bottom to 253°C, 257°C, 259°C and 260°C, and turn on the heating to keep the pressure in the monomer container 1 at 0.03MPa;

[0037] S2. After the modified asphalt is heated to 250° C., the temperature is maintained for 13 hours to obtain the high softening point asphalt.

[0038] Finally, the softening point of the high softening point pitch prepared in this example is 250°C, the fixed carbon content is 81%wt, and the ash content is 0.5%wt.

[0039] Utilize this high softening point pitch as raw material to prepare binding agent, after measuring, the softening point of described binding agent is 250 ℃, and fixed carbon content is 80%wt, and ash con...

Embodiment 2

[0041] The preparation method of high softening point asphalt, the step comprises:

[0042] S1. Import the modified asphalt into the monomer container 1, and pass an inert gas into the monomer container 1. The inert gas is nitrogen, and the heating temperature of the four-stage electric heater 3 is adjusted to 354°C from top to bottom. , 355°C, 356°C and 358°C, and turn on the heating to keep the pressure in the monomer container 1 at 0.04MPa;

[0043]S2. After the modified asphalt is heated to 350° C., the temperature is maintained to continue the reaction for 16 hours to obtain the high softening point asphalt.

[0044] Finally, the softening point of the high softening point pitch prepared in this example is 350°C, the fixed carbon content is 87%wt, and the ash content is 0.45%wt.

[0045] Using the high softening point pitch as raw material to prepare a binder, the softening point of the binder is determined to be 350°C, the fixed carbon content is 86%wt, and the ash cont...

Embodiment 3

[0047] The preparation method of high softening point asphalt, the step comprises:

[0048] S1. Import the modified asphalt into the monomer container 1, and pass an inert gas into the monomer container 1. The inert gas is nitrogen, and the heating temperature of the four-stage electric heater 3 is adjusted to 375°C from top to bottom. , 376°C, 378°C and 382°C, and turn on the heating to keep the pressure in the monomer container 1 at 0.05MPa;

[0049] S2. After the modified asphalt is heated to 370° C., the temperature is maintained for 18 hours to obtain the high softening point asphalt.

[0050] Finally, the softening point of the high softening point pitch prepared in this example is 370°C, the fixed carbon content is 89%wt, and the ash content is 0.42%wt.

[0051] A binder was prepared using the high softening point pitch as a raw material. After measurement, the softening point of the binder was 250°C, the fixed carbon content was 88%wt, and the ash content was 0.42%wt....

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com