Electro-spinning nano fibre nonwoven production apparatus

A technology of nanofibers and production equipment, which is applied in non-woven fabrics, textiles, papermaking, fiber processing, etc., and can solve problems such as difficult insulation control, low production rate, and no good solution for the safety of mass production equipment. , to achieve good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

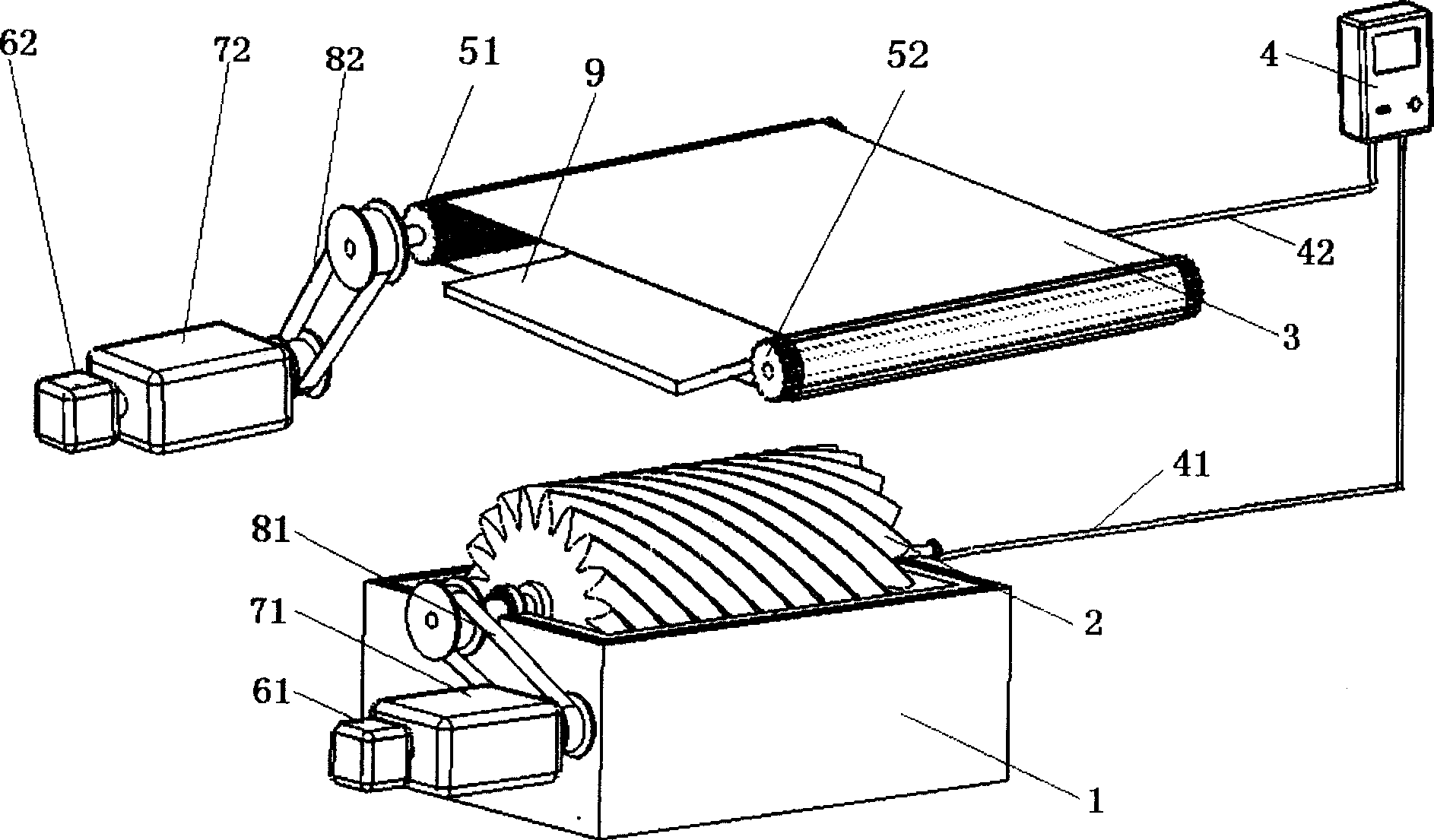

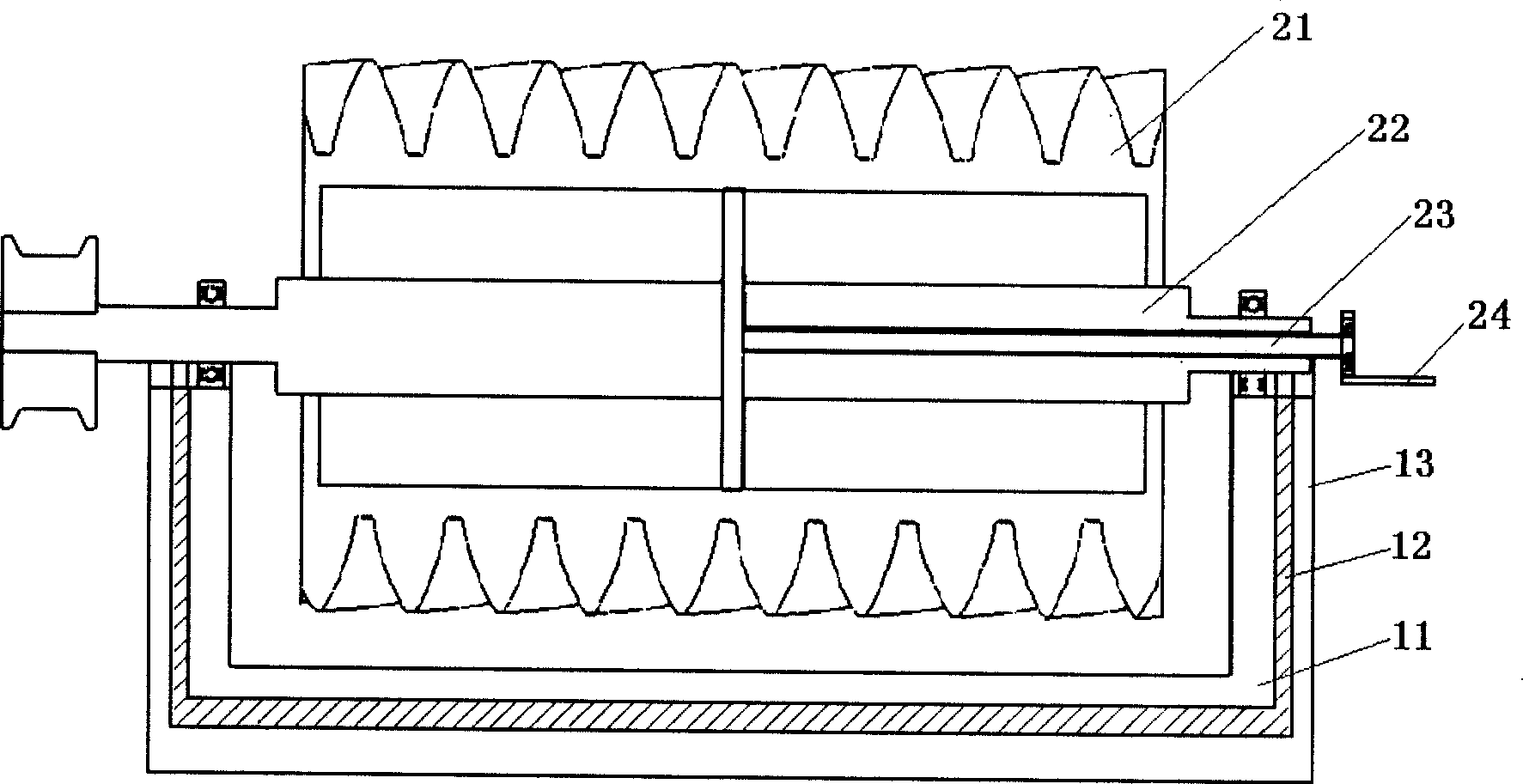

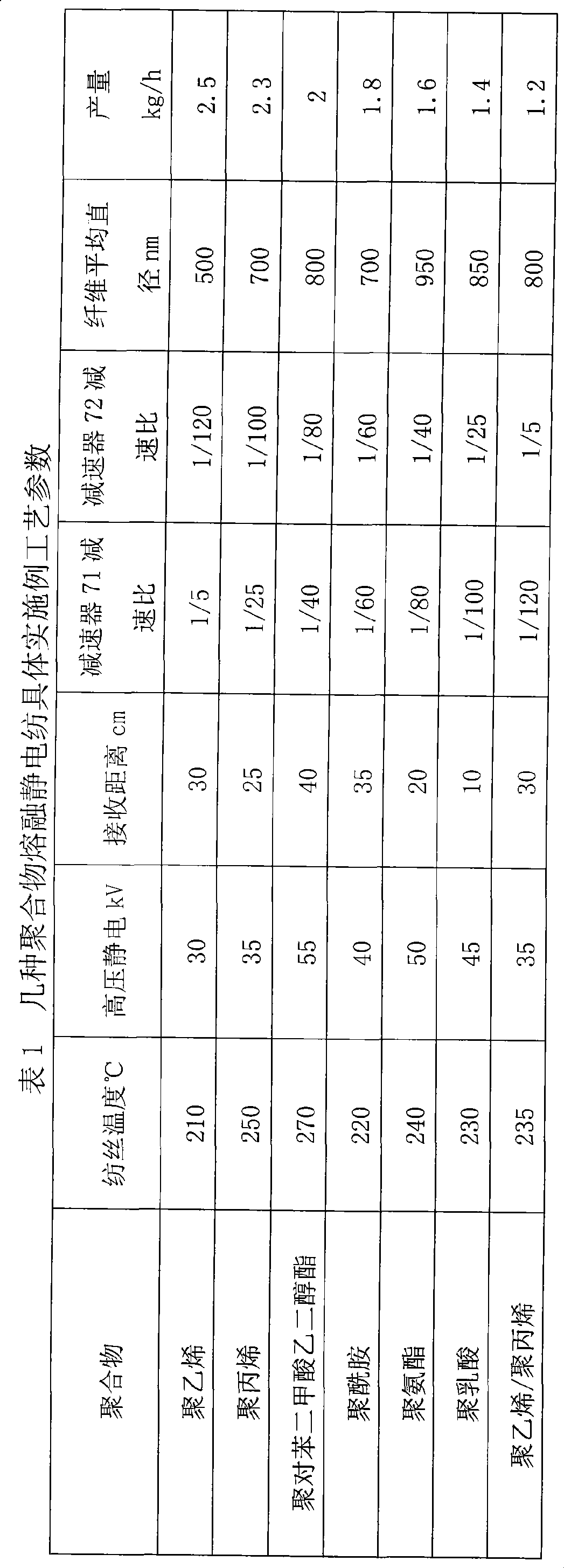

[0021] Such as figure 1An electrospinning device that can mass-produce nanofibers is shown, including a melting pool 1, a metal drum 2, a receiving mesh curtain 3, a high-voltage electrostatic generator 4, a guide roller 5, a synchronous motor 6, a reducer 7, and a pulley 8 , Grounded metal plate 9, etc. During work, the polymer slices are placed in the melting pool 1, the middle heating plate 12 of the melting pool is connected, different heating temperatures are set according to different polymer raw materials, and the driving DC motor 61 and the reducer 71 are turned on at the same time, and the synchronous motor 61 rotates at a speed of 600 rpm, the reduction ratio of the reducer 71 is set to 1 / 5~1 / 240, so that the metal drum 2 is rotated, the metal drum 2 is engraved with tapered threads 21, and the inside is a cavity; when the polymer is completely melted and mixed evenly Finally, turn on the high-voltage electrostatic generator 4, and its positive electrode 41 is conne...

Embodiment 2

[0023] Such as figure 1 An electrospinning device that can mass-produce nanofibers is shown, including a melting pool 1, a metal drum 2, a receiving mesh curtain 3, a high-voltage electrostatic generator 4, a guide roller 5, a synchronous motor 6, a reducer 7, and a pulley 8 , Grounded metal plate 9, etc. When working, polymer slices are placed in the melting pool 1, solvent is added in a certain proportion, the heating plate 12 in the middle of the melting pool is connected, different melting temperatures are set according to different polymer raw materials, and the driving DC motor 61 and reducer 71 are turned on at the same time , the rotating speed of the synchronous motor 61 is 600 rpm, and the reduction ratio of the reducer 71 is set to 60-120, so that the metal drum 2 is rotated. The metal drum 2 is engraved with tapered threads 21 on the outside, and the inside is a cavity; the polymer is completely dissolved and After mixing evenly, turn on the high-voltage electrost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com